Method for preparing sheet shaped nano-graphite lubricating oil additive agent

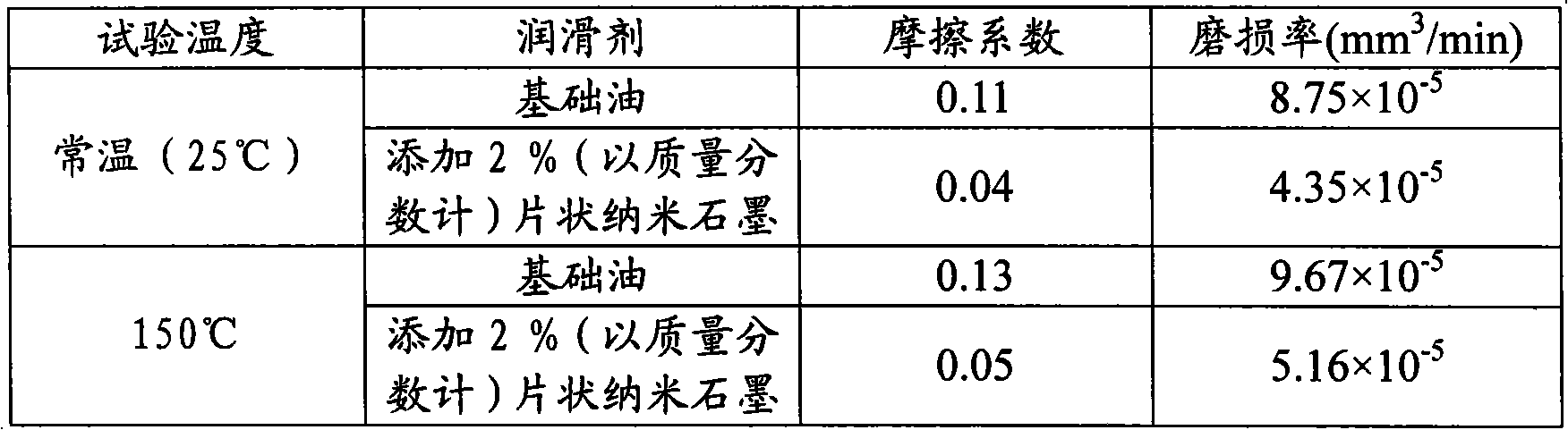

A lubricating oil additive and nano-graphite technology, which is applied in additives, petroleum industry, lubricating compositions, etc., can solve the problems of uneven expansion of expanded graphite, large differences in thickness of nano-graphite flakes, and insufficient natural graphite intercalation treatment. , to achieve the effect of reducing material loss and energy consumption, and improving friction and wear behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] (a) Preparation of primary expanded graphite: Under laboratory conditions, expanded graphite was prepared by chemical method. Wherein, the raw material used is natural flake graphite with a particle size of 50 meshes (purity: 99.9%, origin: Shandong Nanshu Graphite Company), the intercalation agent is concentrated sulfuric acid with a concentration of 98%, and the oxidant is hydrogen peroxide with a concentration of 30%. Intercalation treatment at room temperature of about 25°C for 10 minutes, and then, the intercalated product was washed with water to a pH value of 8, and then dried at 100°C for 2 hours, and high-temperature puffing treatment was performed at a temperature of 800°C. A primary expanded graphite with an expansion factor of about 200 times is obtained.

[0012] (b) Preparation of expanded graphite worms: using primary expanded graphite as raw material, 98% concentrated sulfuric acid as intercalation agent, 30% hydrogen peroxide as oxidant, and intercalati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com