Manganese dioxide modified fiber fabric composite material for ultrasonic motor and its preparation method and application

An ultrasonic motor and fiber fabric technology is applied in the field of manganese dioxide modified fiber fabric composite material for ultrasonic motor and its preparation field, which can solve the problem that the friction performance needs to be improved, so as to improve the tribological performance, improve the bearing capacity, and improve the friction. The effect of wear behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a manganese dioxide modified fiber fabric composite material for an ultrasonic motor, comprising the following steps:

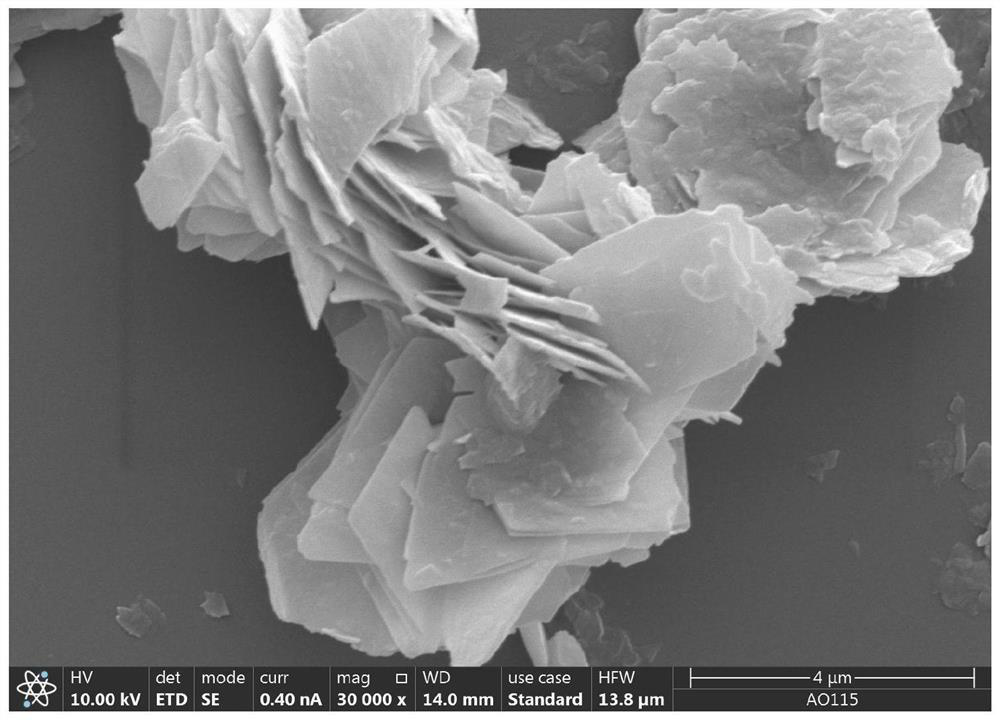

[0024] Mix and disperse phenolic resin, lamellar nano-manganese dioxide, lubricating filler and organic solvent to obtain impregnating solution;

[0025] Immersing the fabric in the impregnating solution, curing and molding the impregnated fabric to obtain a manganese dioxide modified fiber fabric composite material for ultrasonic motors;

[0026] The fabric is a fabric mixed with aramid fiber and glass fiber.

[0027] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0028] The invention mixes and disperses the phenolic resin, the sheet-layer nano manganese dioxide, the lubricating filler and the organic solvent to obtain the impregnating liquid. The present invention has no special limita...

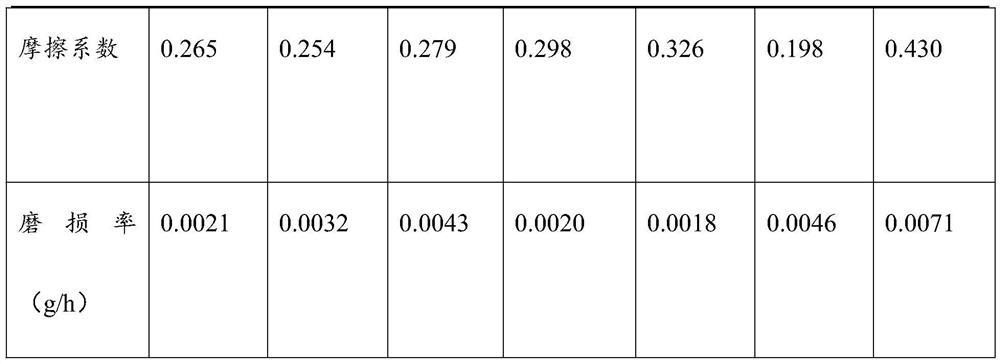

Embodiment 1

[0045] Phenolic resin, acetone, sheet-layer nano-manganese dioxide and polytetrafluoroethylene were mixed by quality 4g, 8g, 0.8g and 2.2g respectively, and ultrasonic (500W) was dispersed for 35min to obtain the impregnation solution; the fabric (the thickness of the fabric was 0.20 ~ 0.22mm) in the impregnation solution for 20 minutes, then moved to 80 ° C blast oven to dry for 60 minutes, repeated dipping-drying steps until the weight of the fabric increased by 60%, and the resulting dried fabric with phenolic resin Stick it on the surface of titanium alloy, apply a pressure of 0.3MPa, raise it from room temperature to 150°C at a speed of 10°C / min, cure for 5 hours, and then shape it to obtain a manganese dioxide-modified fiber fabric composite material for ultrasonic motors.

Embodiment 2

[0047] Phenolic resin, ethyl acetate, lamellar nano-manganese dioxide and graphite were mixed by quality 20g, 40g, 0.1g and 1.8g respectively, and ultrasonic (500W) was dispersed for 25min to obtain the impregnating solution; the fabric (the thickness of the fabric was 0.20 ~0.22mm) was immersed in the impregnation solution for 10 minutes, then moved to a blast oven at 70°C to dry for 30 minutes, and repeated the steps of immersion-drying until the weight of the fabric increased by 50%, and the resulting dried fabric was pasted with phenolic resin Apply a pressure of 0.1MPa on the surface of the aluminum alloy, raise it from room temperature to 120°C at a rate of 5°C / min, cure for 2 hours, and then shape it to obtain a manganese dioxide-modified fiber fabric composite material for ultrasonic motors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com