High-abrasion-resistance lubricating oil containing carbon nitride-graphene additive and preparation method thereof

A technology of graphene and carbon nitride, which is applied in the field of lubricating oil, can solve problems such as unsatisfactory performance of lubricating oil and affect dispersion stability, and achieve the effects of small friction coefficient, improved dispersion, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

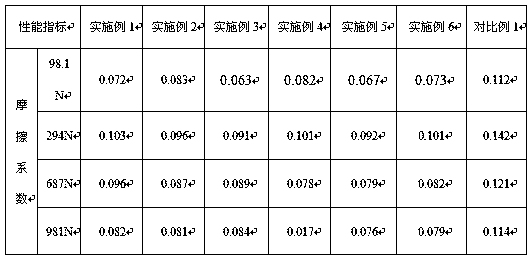

Examples

Embodiment 1

[0033] The preparation process is:

[0034] (1) Disperse two-dimensional carbon nitride nanosheets in excess copper chloride and graphene colloidal solution, soak the surface of carbon nitride in the colloidal solution, then filter, filter out excess colloidal substances, dry, and In a hydrogen environment, treat at 450°C for 10 minutes to reduce copper chloride to copper, and fix graphene on the surface of two-dimensional carbon nitride; High temperature makes the copper on the surface of carbon nitride slightly melt, further leveling and fixing graphene, and making a wear-resistant composite additive for carbon nitride supported graphene; the colloidal solution is copper chloride, graphene, polyvinyl alcohol , Water is formulated with a mass ratio of 1:5:0.1:20. The inert gas is helium;

[0035](2) Add the composite additive prepared in step (1) to the lubricating base oil, mix well, then add viscosity index improver, dispersant, detergent, anti-oxidant, anti-corrosion and...

Embodiment 2

[0040] The preparation process is:

[0041] (1) Disperse two-dimensional carbon nitride nanosheets in excess copper chloride and graphene colloidal solution, soak the surface of carbon nitride in the colloidal solution, then filter, filter out excess colloidal substances, dry, and In a hydrogen environment, treat at 450°C for 15 minutes to reduce copper chloride to copper, and fix graphene on the surface of two-dimensional carbon nitride; High temperature makes the copper on the surface of carbon nitride slightly melt, further leveling and fixing graphene, and making a wear-resistant composite additive for carbon nitride supported graphene; the colloidal solution is copper chloride, graphene, polyvinyl alcohol , Water is formulated with a mass ratio of 1:5:0.1:20. The inert gas is helium;

[0042] (2) Add the composite additive prepared in step (1) to the lubricating base oil, mix well, then add viscosity index improver, dispersant, detergent, anti-oxidant, anti-corrosion an...

Embodiment 3

[0047] The preparation process is:

[0048] (1) Disperse two-dimensional carbon nitride nanosheets in excess copper chloride and graphene colloidal solution, soak the surface of carbon nitride in the colloidal solution, then filter, filter out excess colloidal substances, dry, and In a hydrogen environment, treat at 450°C for 15 minutes to reduce copper chloride to copper, and fix graphene on the surface of two-dimensional carbon nitride; High temperature makes the copper on the surface of carbon nitride slightly melt, further leveling and fixing graphene, and making a wear-resistant composite additive for carbon nitride supported graphene; the colloidal solution is copper chloride, graphene, polyvinyl alcohol , Water is formulated with a mass ratio of 1:5:0.1:20. The inert gas is helium;

[0049] (2) Add the composite additive prepared in step (1) to the lubricating base oil, mix well, then add viscosity index improver, dispersant, detergent, anti-oxidant, anti-corrosion an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com