Rabbit hair carding machine

A carding machine, rabbit hair technology, applied in the deburring device, textile and paper making, fiber treatment, etc., can solve the problems of low output level, fiber damage, unsuitable carding and carding of rabbit hair fibers, etc., and achieve high technical and economic benefits , The effect of light fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

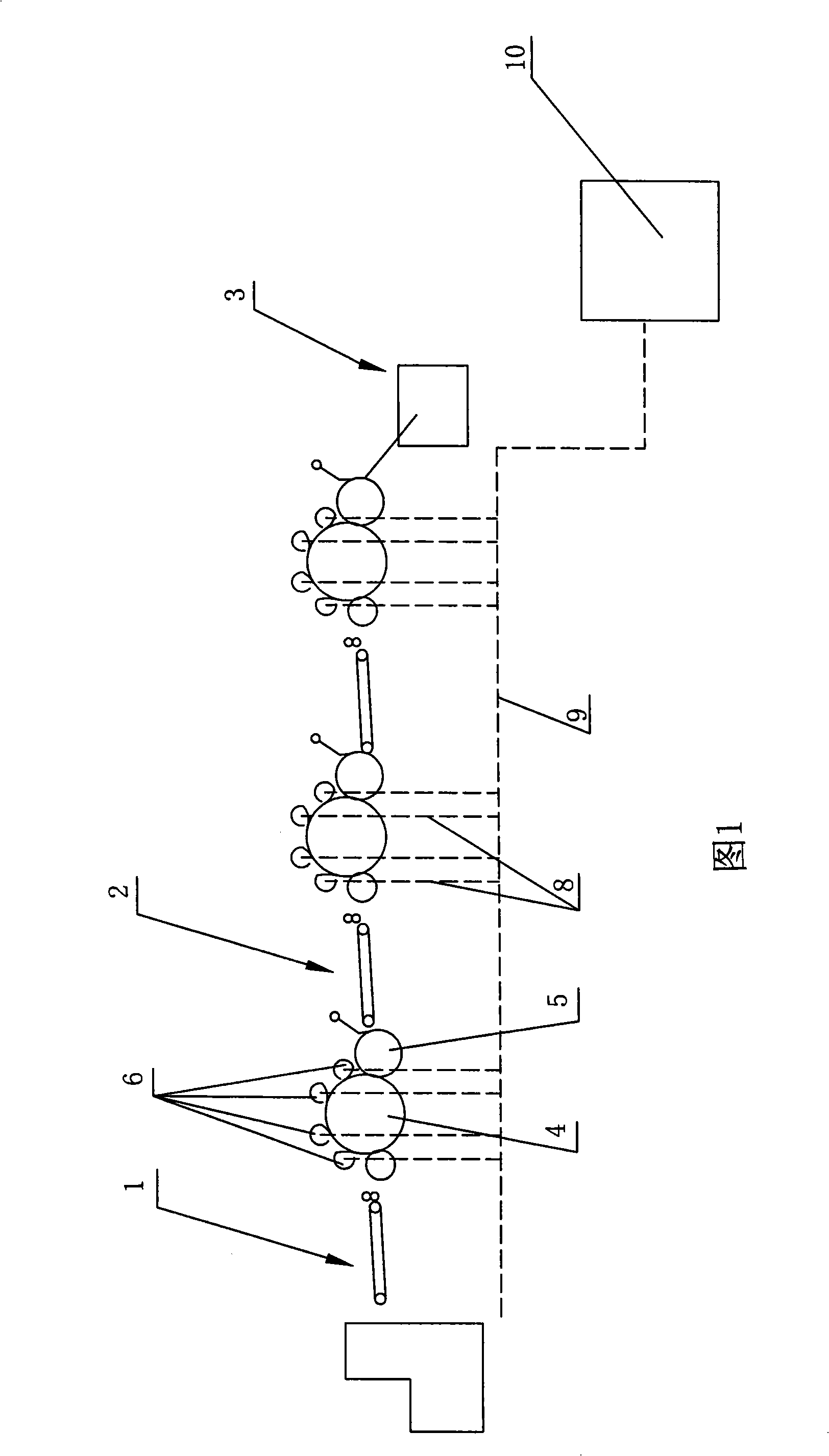

[0026] Combined with Fig. 1, a rabbit hair carding machine, including a hair feeding mechanism 1, a three-section carding device, a bridge mechanism 2, and a cashmere storage box 3, wherein the hair feeding mechanism 1 is at the feeding end of the unit, and the cashmere storage box 3 is at the unit The output end of the bridge mechanism 2 is located between the front and rear carding devices. As for the relevant technical content not specifically mentioned, those skilled in the art can directly adopt or learn from the existing technology and implement it without creative labor.

[0027] The following focuses on explaining the innovative part of the present invention, that is, the technical content of the carding device, and of course also includes some related prior art content.

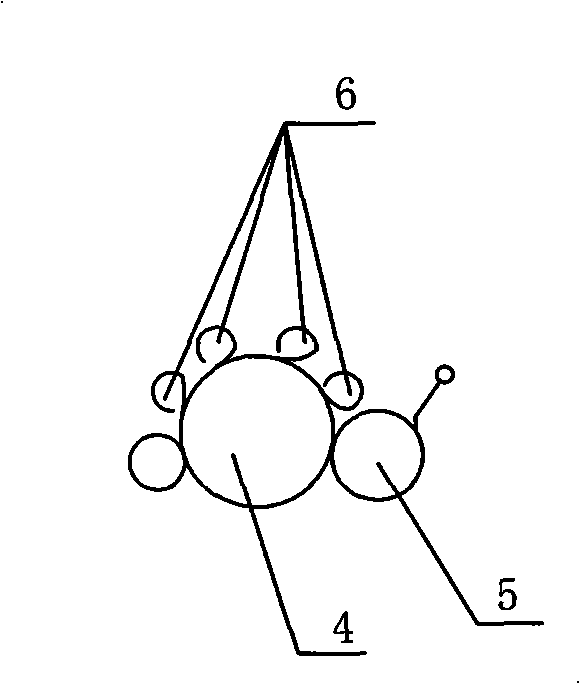

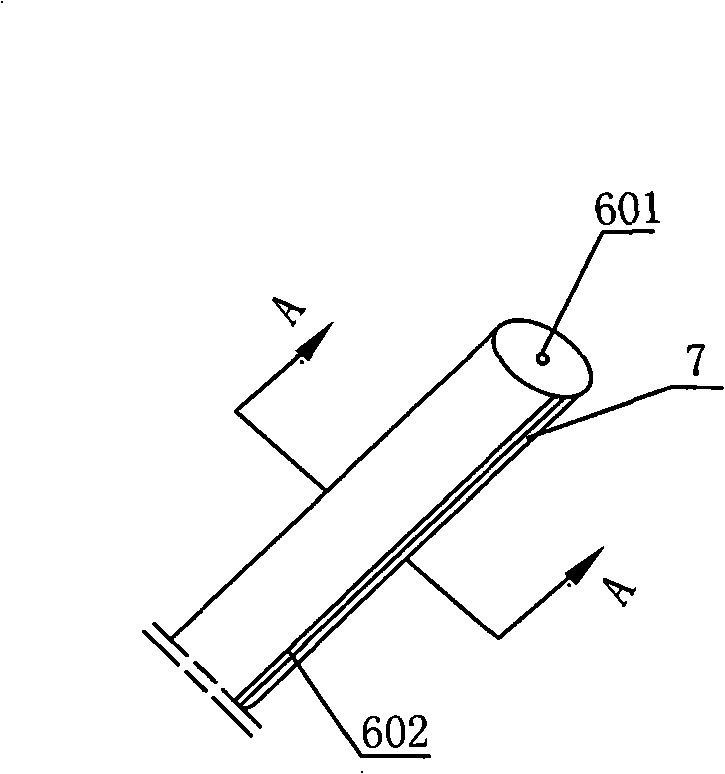

[0028] Carding device embodiment 1, combining figure 2 , image 3 and Figure 4 , taking one (single) carding device as an example, including cylinder 4 and doffer 5. Four negative pressure cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com