Totally-enclosed fluid switch

A fluid switch, fully enclosed technology, used in lift valves, valve details, engine components, etc., can solve problems such as friction damage to soft valve plates, inconvenient use and maintenance, and corrosion of other components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

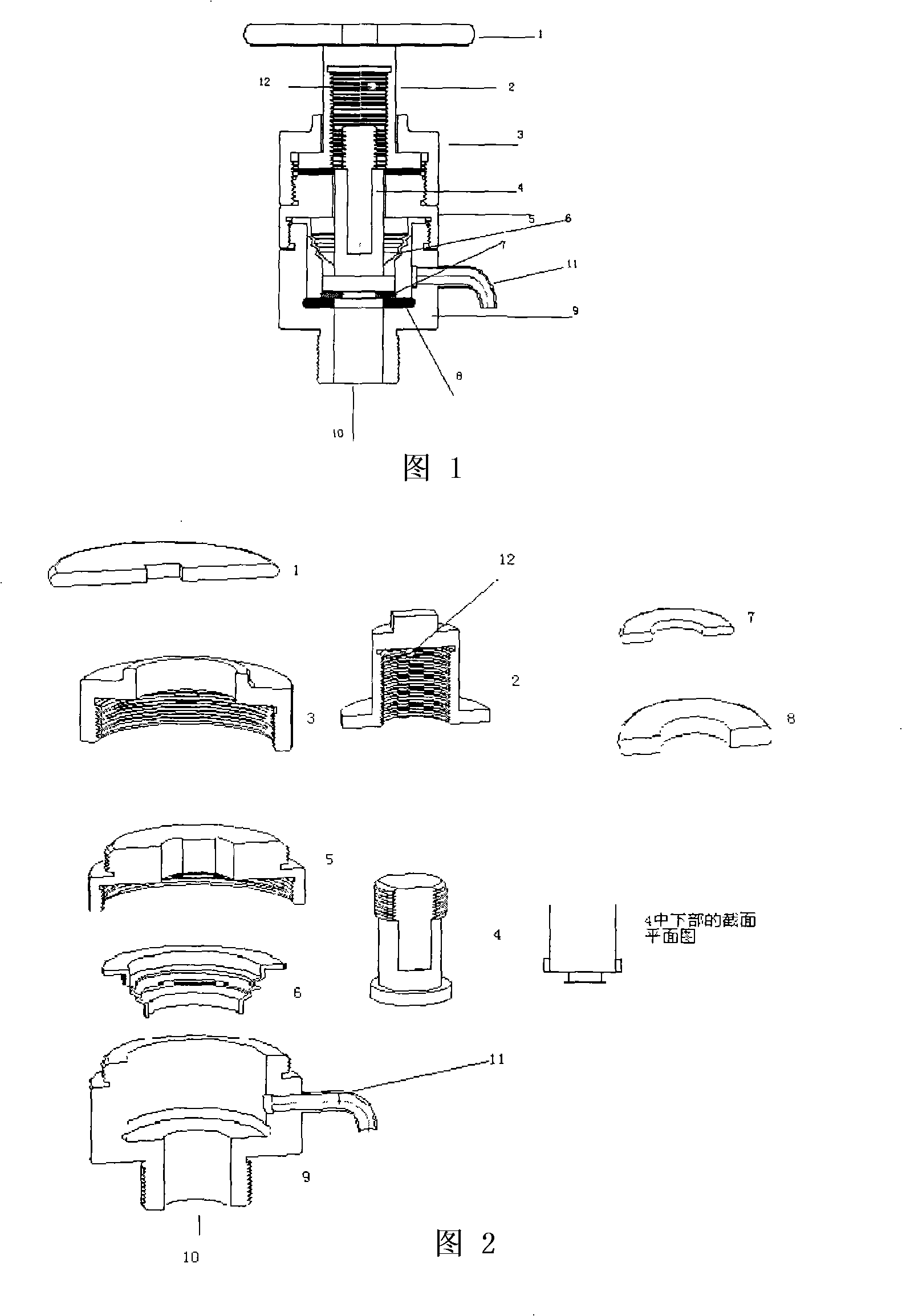

[0048] In order to clearly understand the technical features, innovative features, and innovative effects of the present invention, specific implementation methods thereof will be described below.

[0049] working principle

[0050] When the handle 1 is rotated, the rotating sleeve 2 rotates. At this time, due to the effect of the round hole sleeve 3, the upper and lower positions of the rotating sleeve 2 are fixed accordingly. At the same time, due to the effect of the flat hole outer sleeve 5, the upper and lower The flat bottom circle spindle 4 cannot be fixed left and right with the rotation, but can only move up and down. Finally, due to the relative movement between the screw and the nut when rotating, the top flat bottom circle spindle 4 moves up and down with the rotation of the handle 1, stretching The sleeve 6 also expands and contracts with the up and down movement of the main shaft 4, and the upper valve plate 7 and the lower coupling valve plate 8 appear in an ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com