Driving method of grooved plasma body metal net plate electrode during initialization

A metal mesh, plasma technology, used in cold cathode tubes, instruments, static indicators, etc., can solve the problems of display instability, unstable addressing discharge, screen flicker, and discharge delay.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

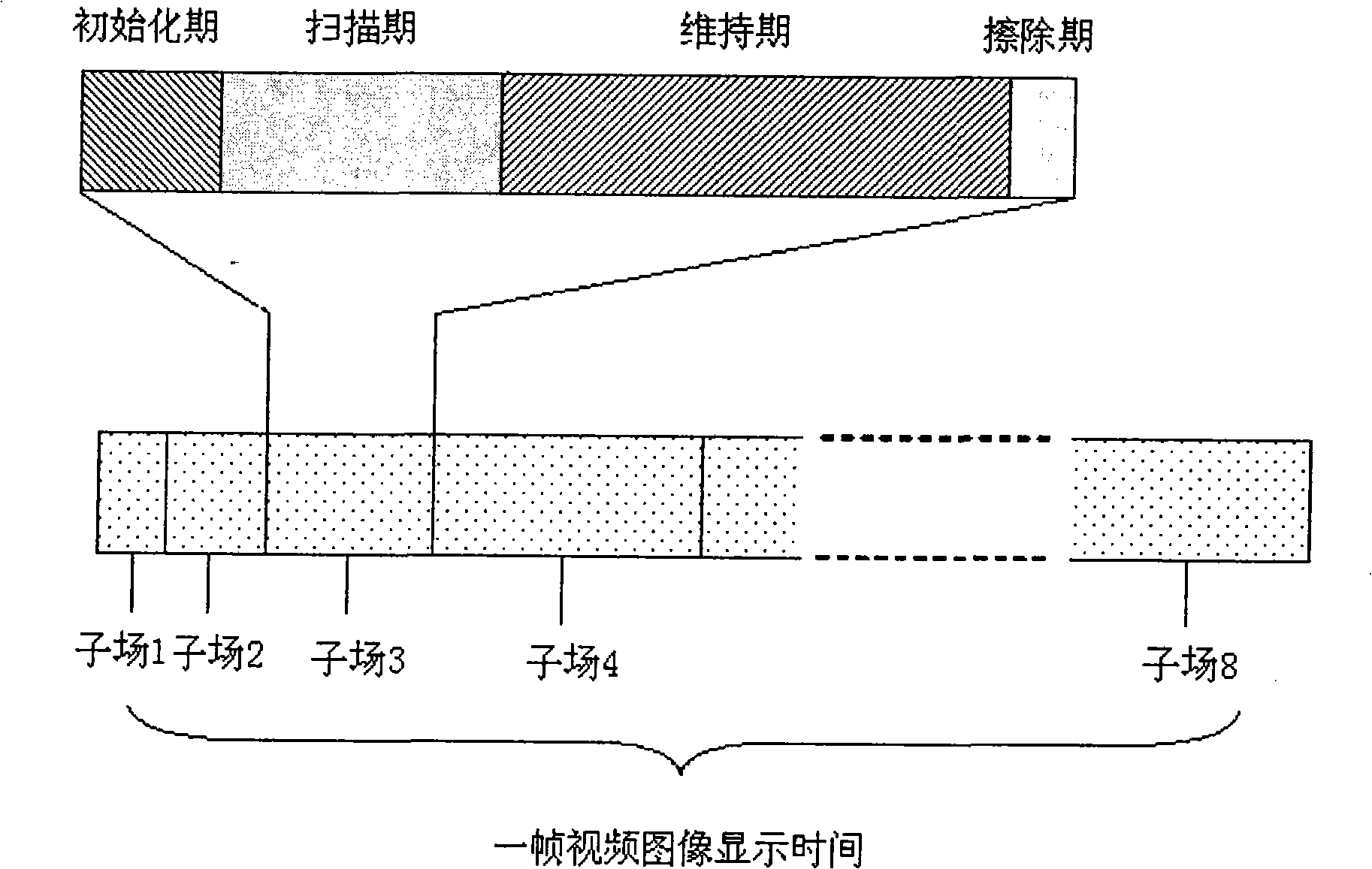

[0105] In the driving method of Example 1, the waveform diagram of the pulses applied to the electrodes during the initialization period is as follows Figure 6 shown.

[0106] exist Figure 5 In the description, the sweep voltage V SCN Parts A2 and A6 in and part B3 of the metal grid plate electrode voltage Vs all take ramp-like waveforms, and in this example 1, such as Figure 6 As shown, the corresponding parts are exponential function waveforms. Except for the voltage waveforms of the above-mentioned parts A2, A6 and B3 during the initialization period, the voltage waveforms of other parts are the same as the above-mentioned Figure 5 The corresponding part in is the same.

[0107] With this driving method, the wall charge is accumulated by adding the voltage of A8 and A9, and the initialization time is shortened by using A1 and A4, that is, the combined waveform of the two waveforms is used as the initialization pulse, and the initialization time Will not lengthen, a...

example 2

[0113] Figure 7 is a waveform diagram of pulses applied to each electrode during initialization in Example 2.

[0114] Such as Figure 7 As shown, the waveform of the applied voltage in Example 2 is characterized in that the intervals that originally used the exponential function waveform in the above-mentioned Variation 1 are changed to a combined waveform composed of a plurality of ramp-shaped waveforms.

[0115] During the period from time t0 to t2, the scanning voltage V SCN The waveform of is composed of two ramp-like waveforms. That is, the period from time t0 to t7 is ramp-shaped waveform 1 (part A10), and the period from time t7 to t2 is ramp-shaped waveform 2 (part A11). In addition, at time t7, there is no gap between waveform 1 and waveform 2 .

[0116] The maximum value of the voltage change rate of the two ramp-shaped waveforms is set below 10V / μsec. As in the above case, this is also to prevent misdischarge.

[0117] Similarly, the scanning voltage VSCN fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com