In-plane buckling composite mode thin type straight line ultrasound electric motor

A linear ultrasonic motor and composite mold technology, applied in the field of electric motors, can solve the problems of high assembly precision requirements for eight piezoelectric ceramic sheets, easy cracking of piezoelectric ceramic plates, and increased motor manufacturing costs, etc., to achieve flexible switching between forward and reverse motion , easy design and processing, and better motor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

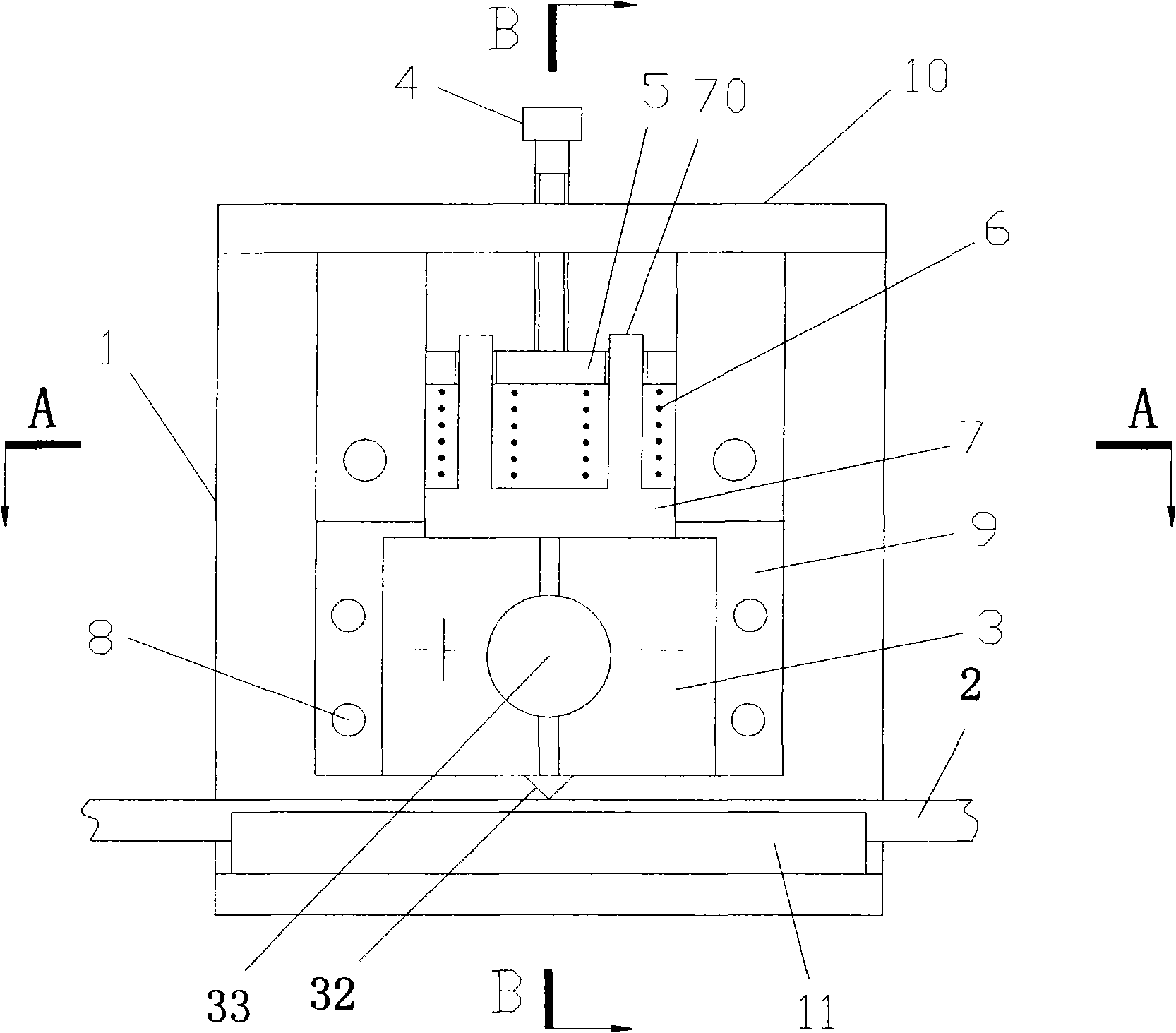

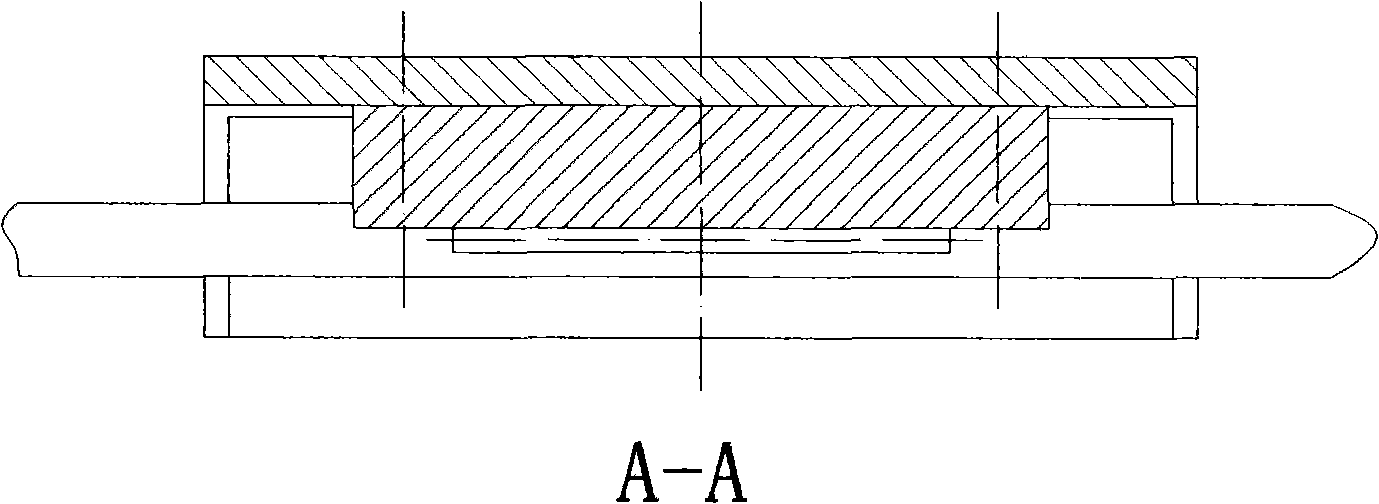

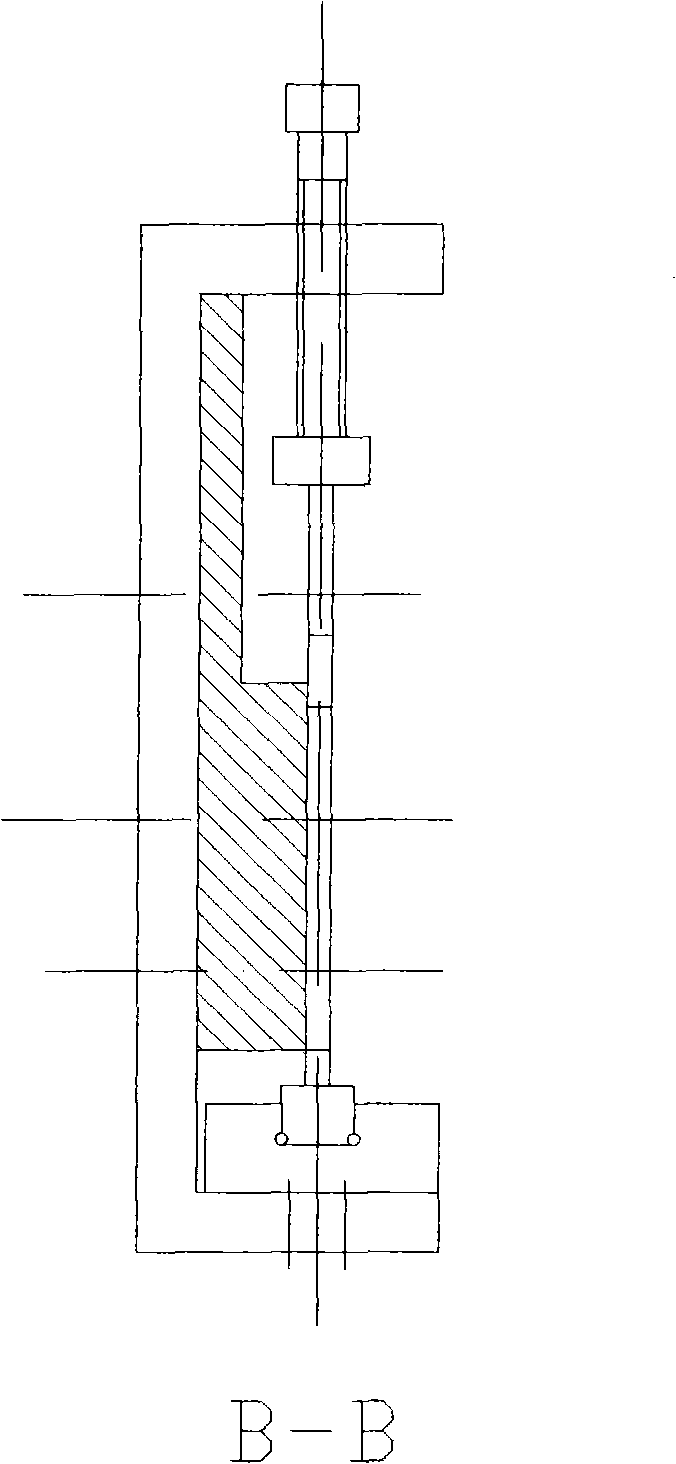

[0027] Such as figure 1 , figure 2 and image 3 The in-plane longitudinal-bending compound mode thin linear ultrasonic motor shown includes a frame 1, a mover 2 that outputs force, a vibrator 3 that excites ultrasonic vibrations, and a preload mechanism that applies contact preload. The mover 2 is a linear slide rail, a sliding seat 11 is fixed in the frame, and the mover 2 is movably mounted on the sliding seat 11. The vibrator 3 includes a rectangular metal elastic plate 30, a rectangular piezoelectric ceramic sheet 31 and a tooth 32, and the metal elastic plate 30 Paste and fix the piezoelectric ceramic sheet 31, paste and fix the shifting tooth 32 at the middle position of the metal elastic plate 30 and the side of the piezoelectric ceramic sheet 31 in the length direction, the shifting tooth 32 is in contact with the mover 2, the top surface of the vibrator 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com