Grid type double-feedback aerogenerator rotor position detecting method

A technology for rotor position detection and wind power generators, which is applied in wind power generation, control generators, electrical components, etc., and can solve problems such as inconvenient maintenance of installed position sensors, complicated working environment, and reduced system reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

[0029] example:

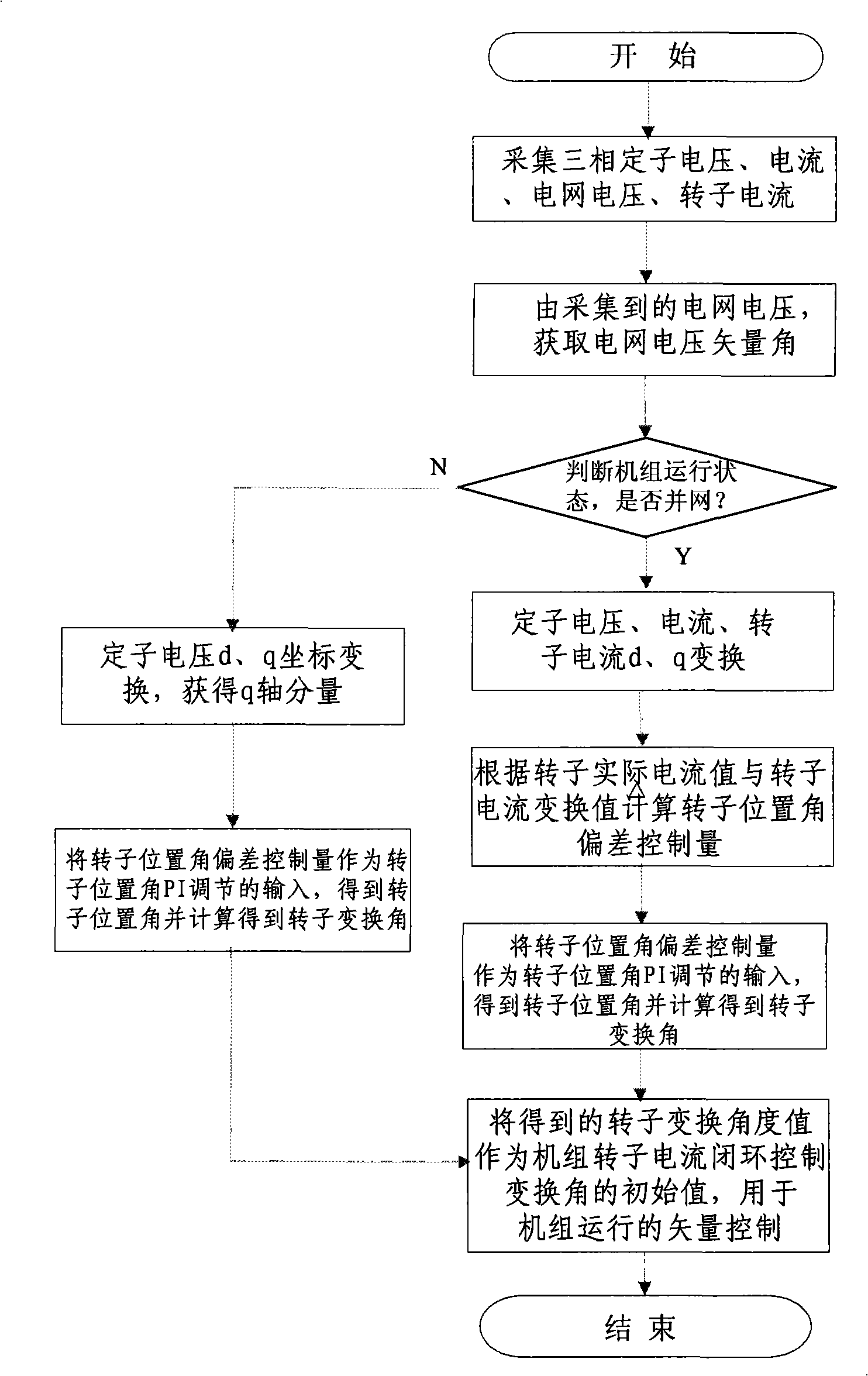

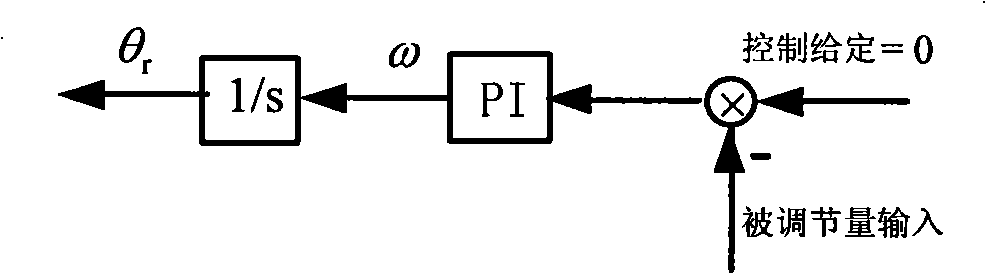

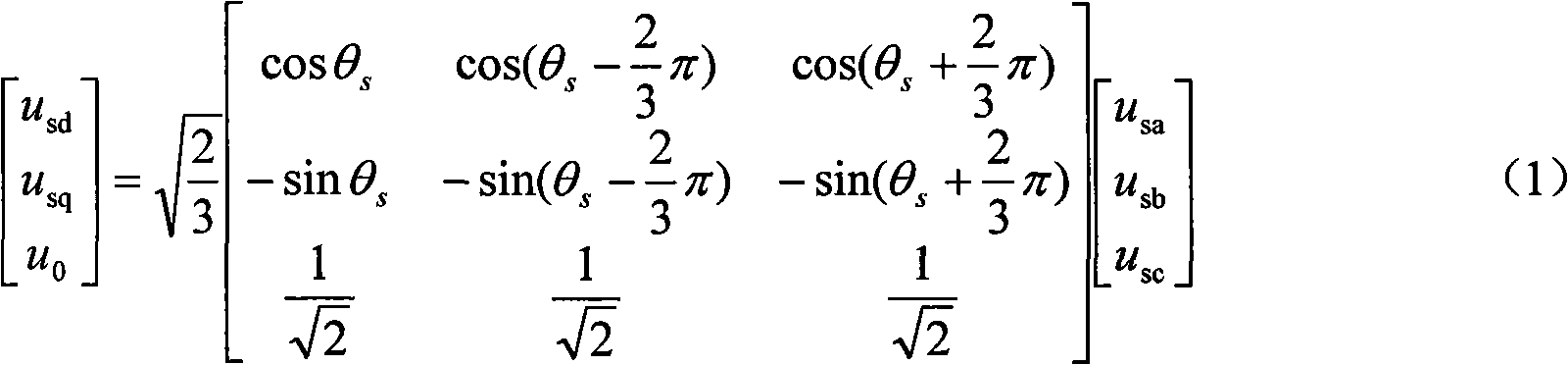

[0030] Here, taking the grid voltage-oriented doubly-fed generator vector control mode as an example, there are: u sd =-ω 1 L m i rq , u sq = 0, ω 1 is the angular velocity of the stator, under the control of the rotor-side converter controller, according to figure 1 The flow shown, the specific implementation steps are as follows:

[0031] Sampling the rotor current, stator voltage, current and grid voltage of the generator; from the collected grid voltage, the grid voltage vector angle θ is obtained through the phase-locked loop s ;Judging the operating status of the unit:

[0032] 1. If the unit is in the no-load excitation control stage before grid connection, the rotor side of the double-fed generator is connected to the converter, and the stator side is ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com