Density contrast automatic fluid discharge valve

A technology of poor automatic and discharge valve, applied in the direction of lift valve, valve details, valve device, etc., it can solve the problems of not being able to control the interface accurately, the need to discharge without exhaustion, and it is difficult to achieve separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

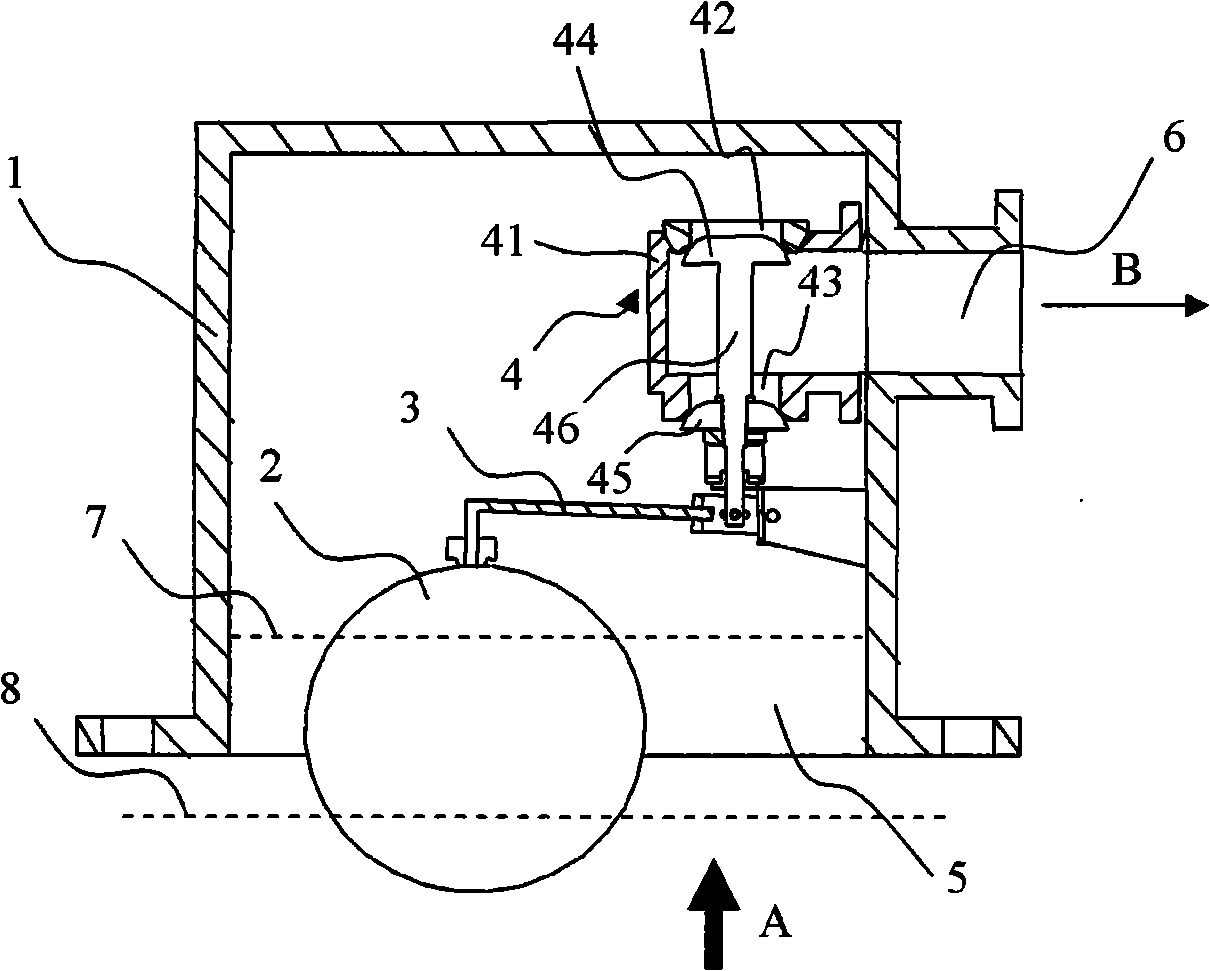

[0014] fit below figure 1 For the specific implementation manner of the present invention, the oil-water mixed liquid is taken as an example for further detailed description.

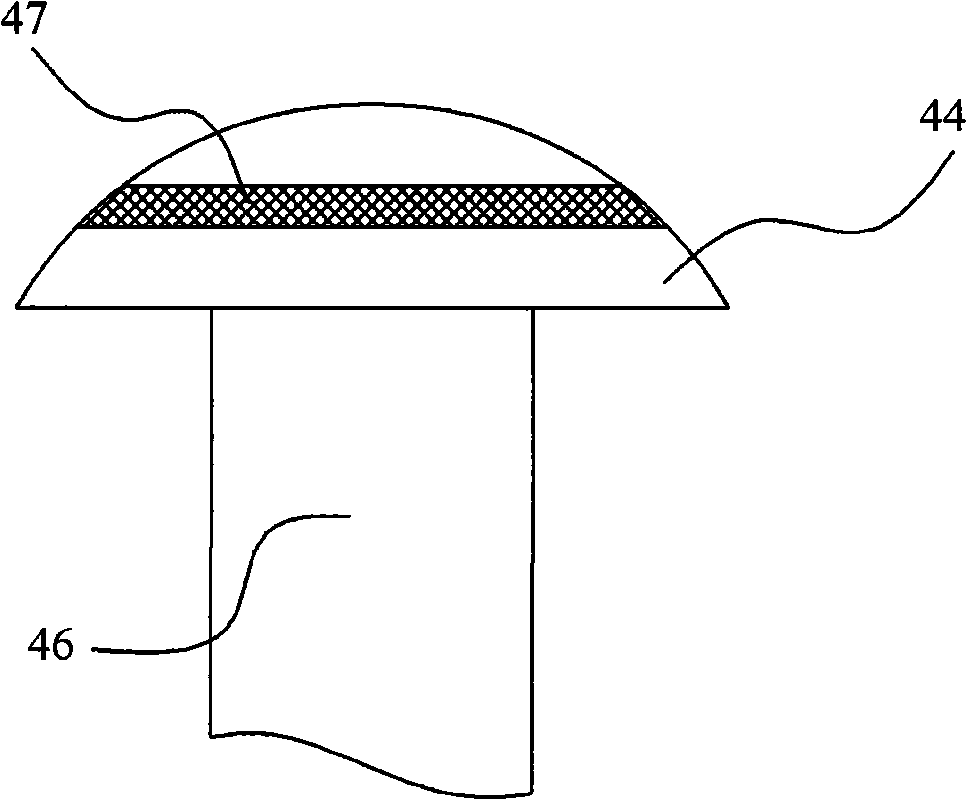

[0015] Such as figure 1 As shown, the present invention includes: a floating ball 2 with a specific gravity between two mixed liquids of oil and water, a casing 1 with an oil-water mixed liquid input port 5 and a single oil liquid discharge port 6, a lever mechanism 3 and a valve port 4, and the valve The port 4 is installed at the position of the discharge port 6 in the shell 1, and the float 2 controls the opening and closing of the valve port 4 through the lever mechanism 3 .

[0016] Since the liquid entering the shell 1 is a mixture of oil and water, a clear interface is formed due to the difference in density between the two, so the floating ball 2 moves between the oil-water interface. The force of the floating ball 2 is buoyancy (f) and its own gravity (mg), and its hovering position and up-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com