Drag reduction pipe

A pipeline and inner tube technology, which is applied in the field of drag reduction pipelines, can solve the problems of high resistance in long-distance pipelines, and achieve the effects of reduced transportation energy consumption, reduced frictional resistance, and reduced resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

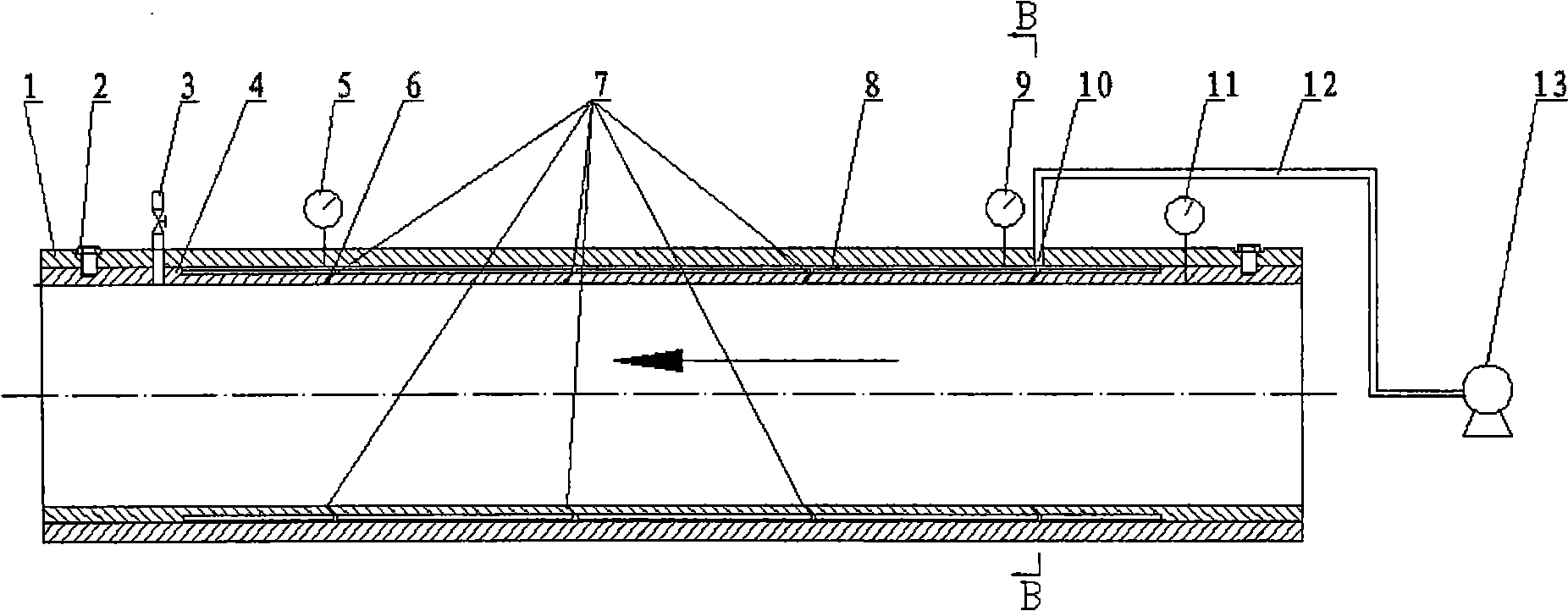

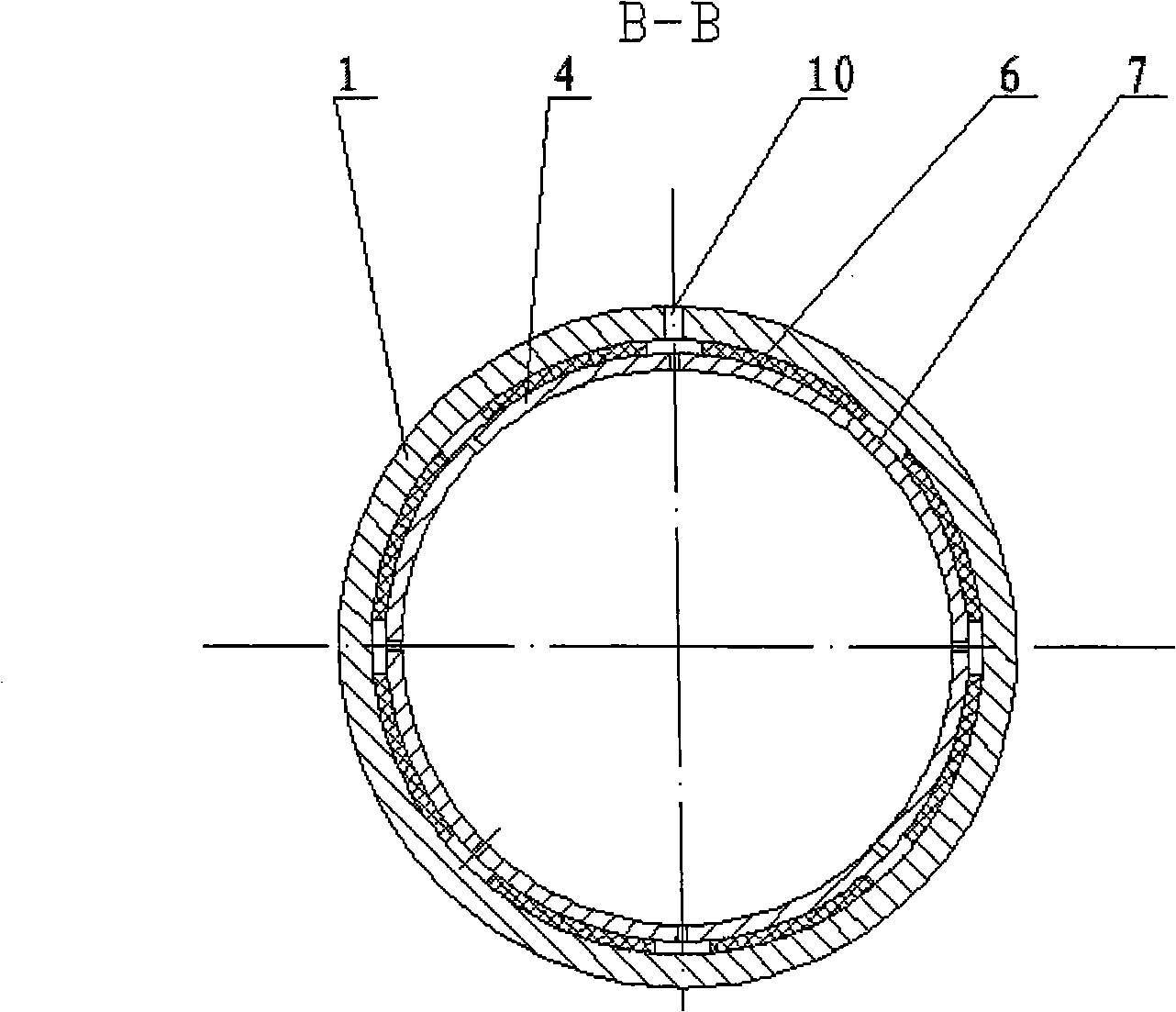

[0015] The pipeline conveying device based on the two-phase flow technology proposed by the present invention has a schematic structural diagram as shown in figure 1 shown. It includes an outer tube 1 and an inner tube 3, which are fixed by connecting screws 2. The outlet end of the air compressor or booster pump 12 is connected to the annular groove 5 through the guide pipe 11 and the guide hole 9, and the inlet pressure gauge 8 and the terminal pressure gauge 4 are respectively installed at the two ends of the outer pipe 1. The inlet end of the tube is also provided with a pressure gauge 10 for measuring the medium in the tube, and the gas entering the axial groove 7 and the circumferential groove 5 with the inlet pressure gauge installed respectively enters the inner tube through the air hole 6.

[0016] The working process of an embodiment of the device of the present invention is described below in conjunction with the accompanying drawings: after the air or low-viscosit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com