Small mode number gear drive error measuring method

A small modulus gear and transmission error technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of small modulus gear micro angular displacement error, which cannot be adopted, and the effect of measuring tiny modulus gear is not ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

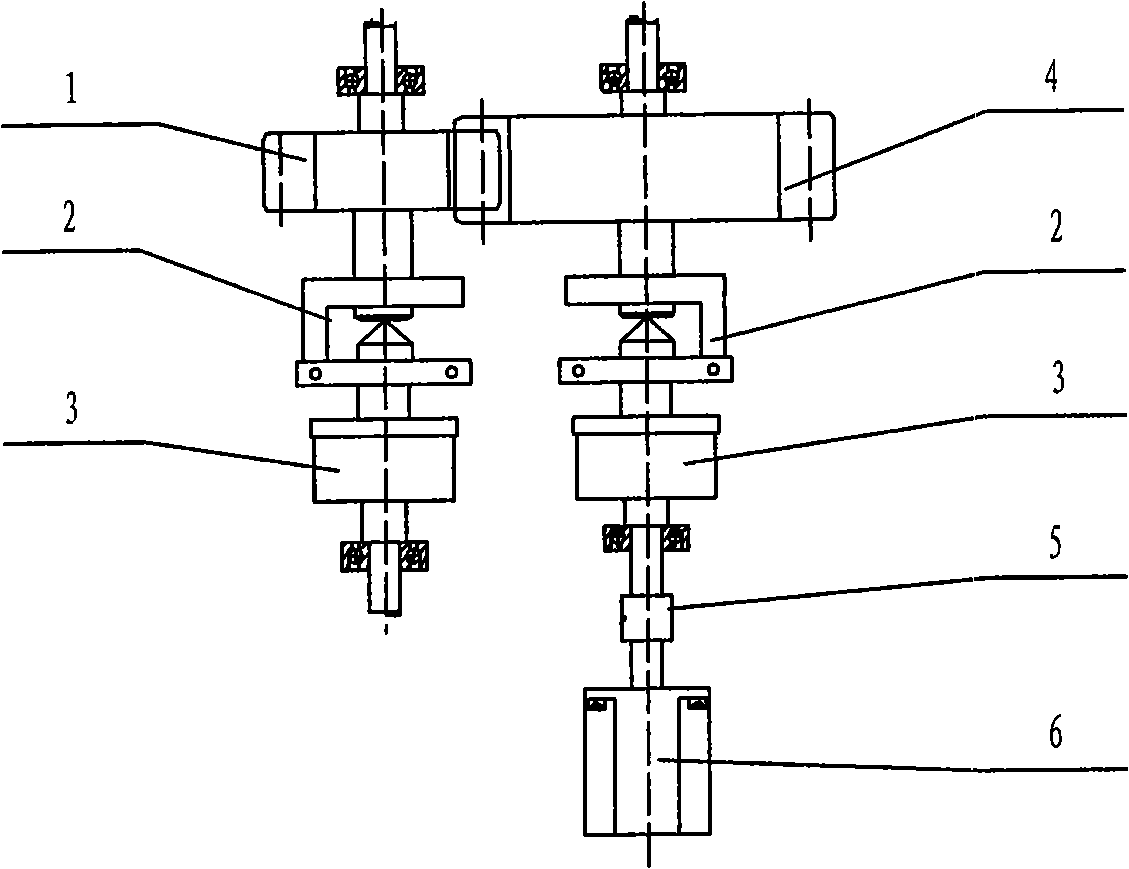

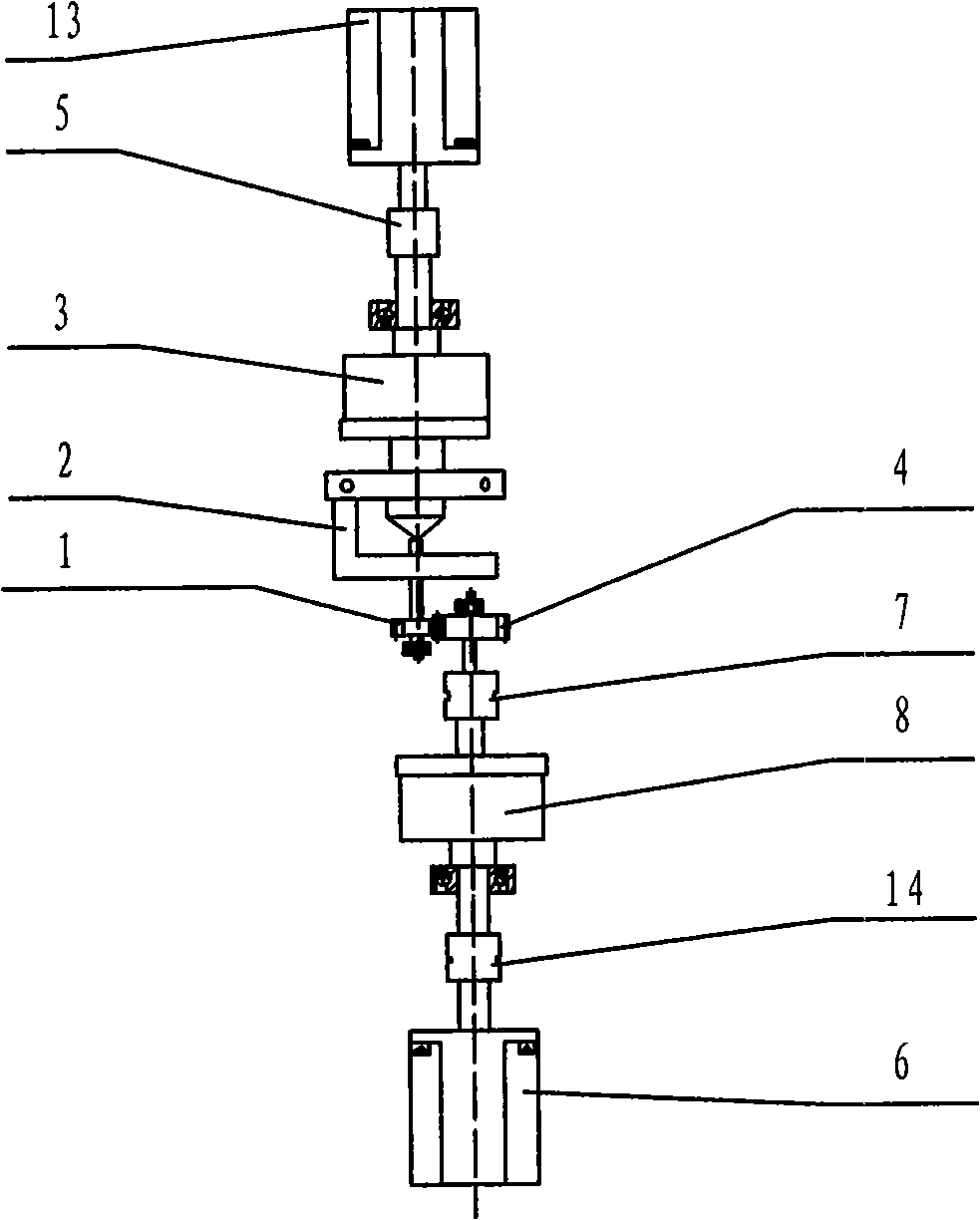

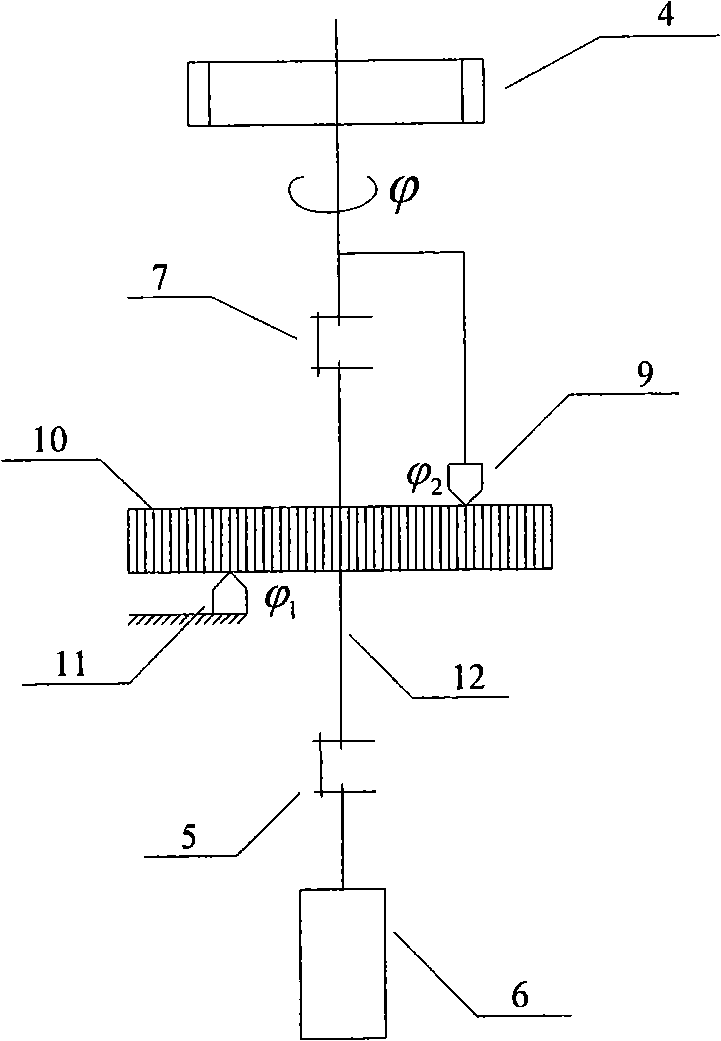

[0024] Attached below figure 2 , 3 The present invention is described further:

[0025] The measurement principle of this embodiment is to change the traditional one-way transmission measurement method into a two-way synchronous drive measurement method. The device is as figure 2 As shown, there are two drive systems included. One set is the measuring gear 4 driving system, which includes the measuring gear 4 , the flexible coupling 7 , the second angle encoder 8 , the second coupling 14 and the second motor 6 . The measuring gear 4 is connected with the flexible coupling 7 , the flexible coupling 7 is connected with the second angle measuring encoder 8 , and the second angle measuring encoder 8 is connected with the second motor 6 through the second shaft coupling 14 . In this way, the second motor 6 drives the second angle measuring encoder 8 , the flexible coupling 7 and the measuring gear 4 to rotate through the second shaft coupling 14 . The other set is the gear un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com