Roll stand provided with a displacement device

A technology of rolling mill stand and rolling mill stand, which is applied in the direction of metal rolling mill stand, driving device for metal rolling mill, metal rolling stand, etc. The effect of improved proximity, simple axial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

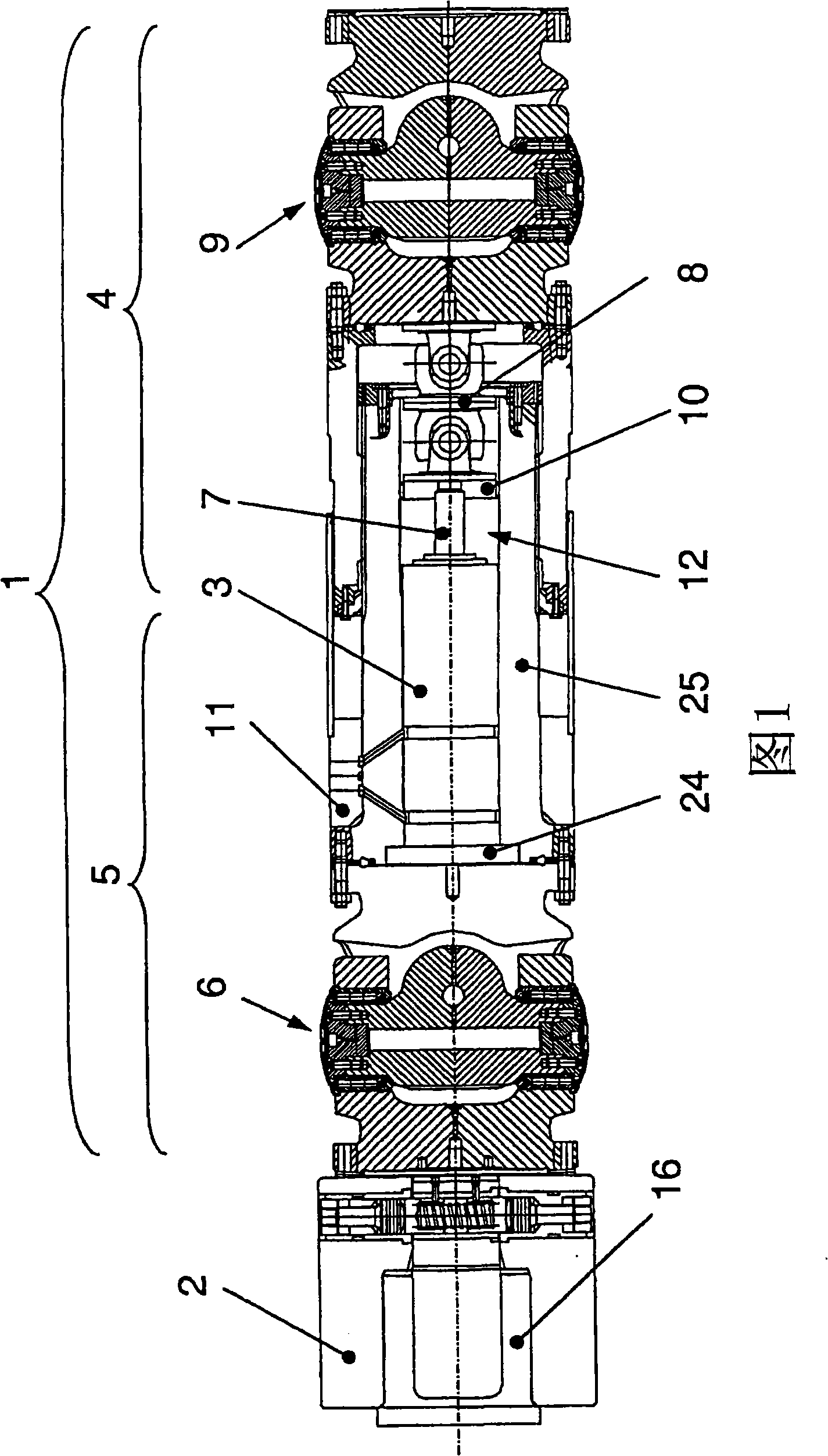

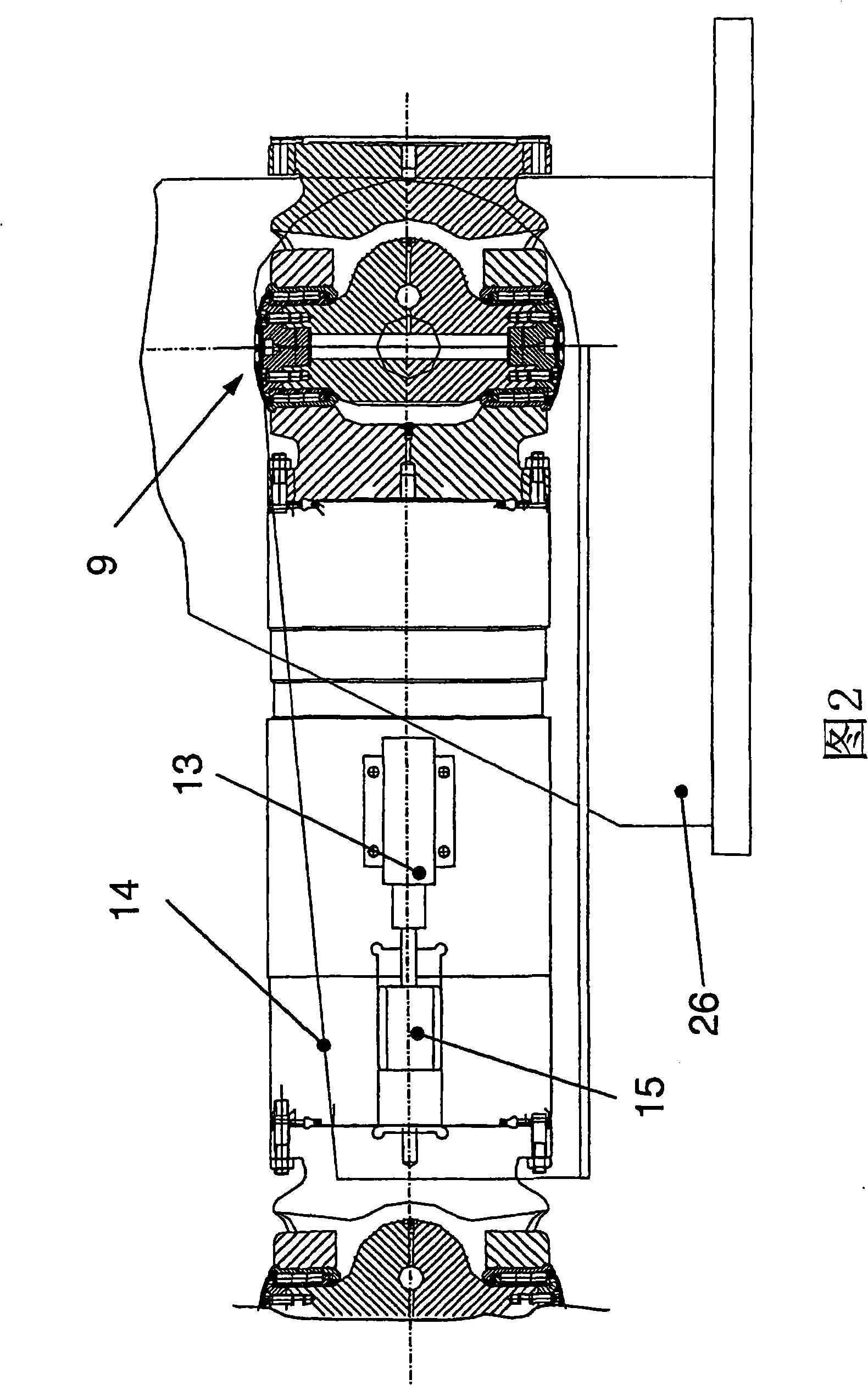

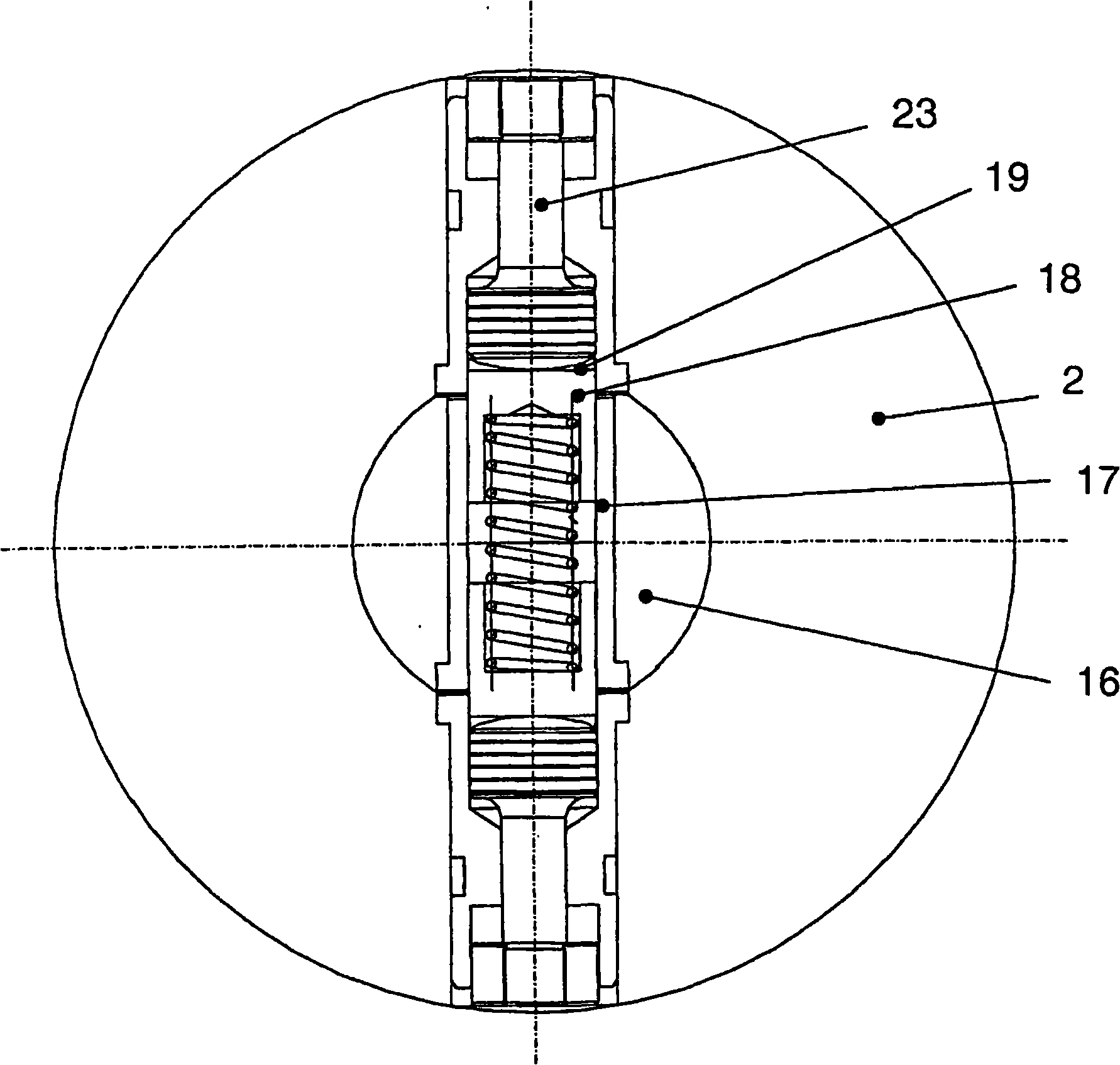

[0036] FIG. 1 shows a transmission shaft ( 1 ) with two shaft parts ( 4 ) and ( 5 ) in section. The shaft part (4) is arranged stationary on the motor side, while the shaft part (5) is arranged displaceable in the axial direction. The drive shaft (1) serves to drive the rollers, wherein height position offsets and axial position changes can be compensated accordingly via the drive shaft (1). The shaft (1) shown has two joints (6, 9). A piston-cylinder unit (3) is arranged in the recess (12) for axially displacing the movable shaft part (5), wherein the cylinder is fixed by means of a cylinder flange (24) to the joint head (6) and Between the drive shaft inner parts (25). The piston rod (7) is guided radially within the drive shaft inner part (25) by means of a guide disc (10). The piston rod (7) is connected to the joint head (9) via the guide disc (10) and the connecting joint (8), wherein unavoidable axial offsets can be compensated and thus avoid damage to the piston-cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com