Novel bone surgery fixing system and method of use thereof and polyurethane applied therein

A fixation system and orthopedic surgery technology, applied in fractures, medical science, surgery, etc., can solve the problems of difficulty in transmitting X-rays, inability to detach, and high cost, achieving superior cost performance, no infection, and ideal effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

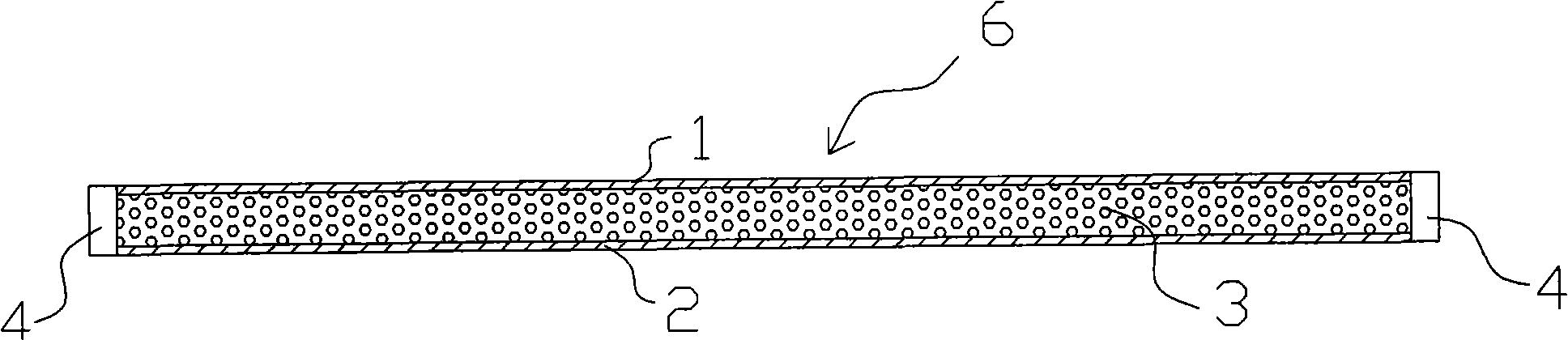

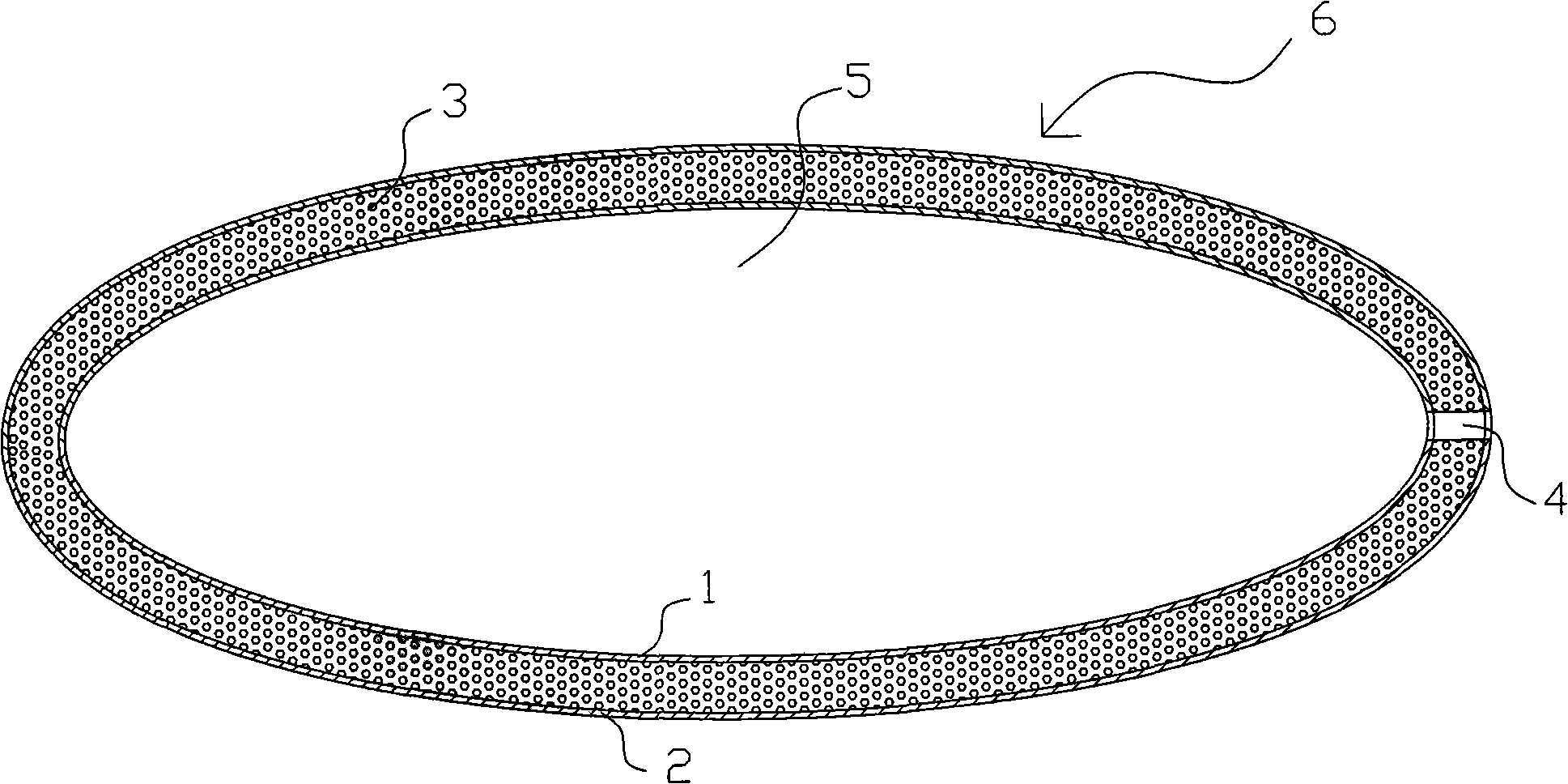

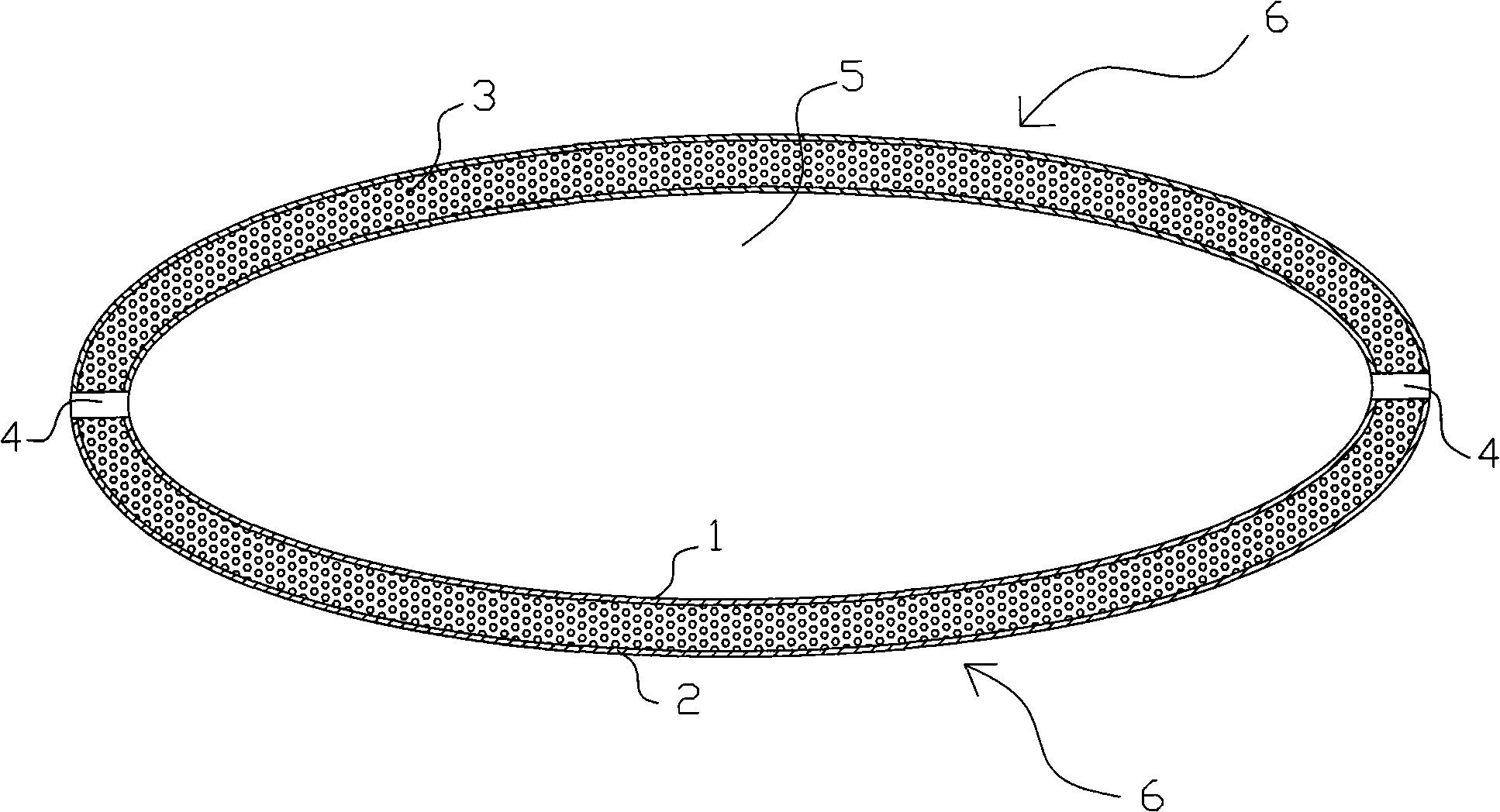

[0047] Mixture B is composed of 90 parts by weight of polyether polyol, 0.3 parts by weight of dimethylcycloethylamine, 2 parts by weight of silicone stabilizer, 7.7 parts by weight of water and 141B, first take 250ml of compound A liquefied MDI Mix with 250ml of mixture B, stir and mix well, fill the polyurethane slurry into the interlayer of two cotton cavities, push it evenly with a roller, and spread it out. After about 1 to 2 minutes, the polyurethane will change from liquid Enter the solid-state softening section, at this time, wrap the two cotton cavities on the desired fixed part, pull up the zipper, shape it by hand to make it close to the desired fixed part, and keep the injured part of the patient still for 8~ After 8.5 minutes, the shaping is completed. At this time, the polyurethane enters the solid hardening section, and after another 20 minutes, the shaping of the orthopedic surgery fixation system is completed, and a flexible fixation system is obtained.

Embodiment 2

[0049] Mixture B is composed of 93 parts by weight of polyether polyol, 1 part by weight of dimethylethanolamine, 4 parts by weight of silicone stabilizer, 2 parts by weight of water and 141B, first take 250ml of compound A liquefied MDI and 250ml The mixture B was mixed, and the rest of the operation steps were the same as in Example 1, and finally a flexible fixing system was obtained.

Embodiment 3

[0051] Mixture B consists of 90 parts by weight of polyether polyol, 1 part by weight of dimethylethanolamine, 4 parts by weight of silicone stabilizer, 5 parts by weight of water and 141B. First, take 250ml of compound A liquefied MDI and 500ml of The mixture B was mixed, and the rest of the operating steps were the same as in Example 1, and finally a rigid fixed system was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com