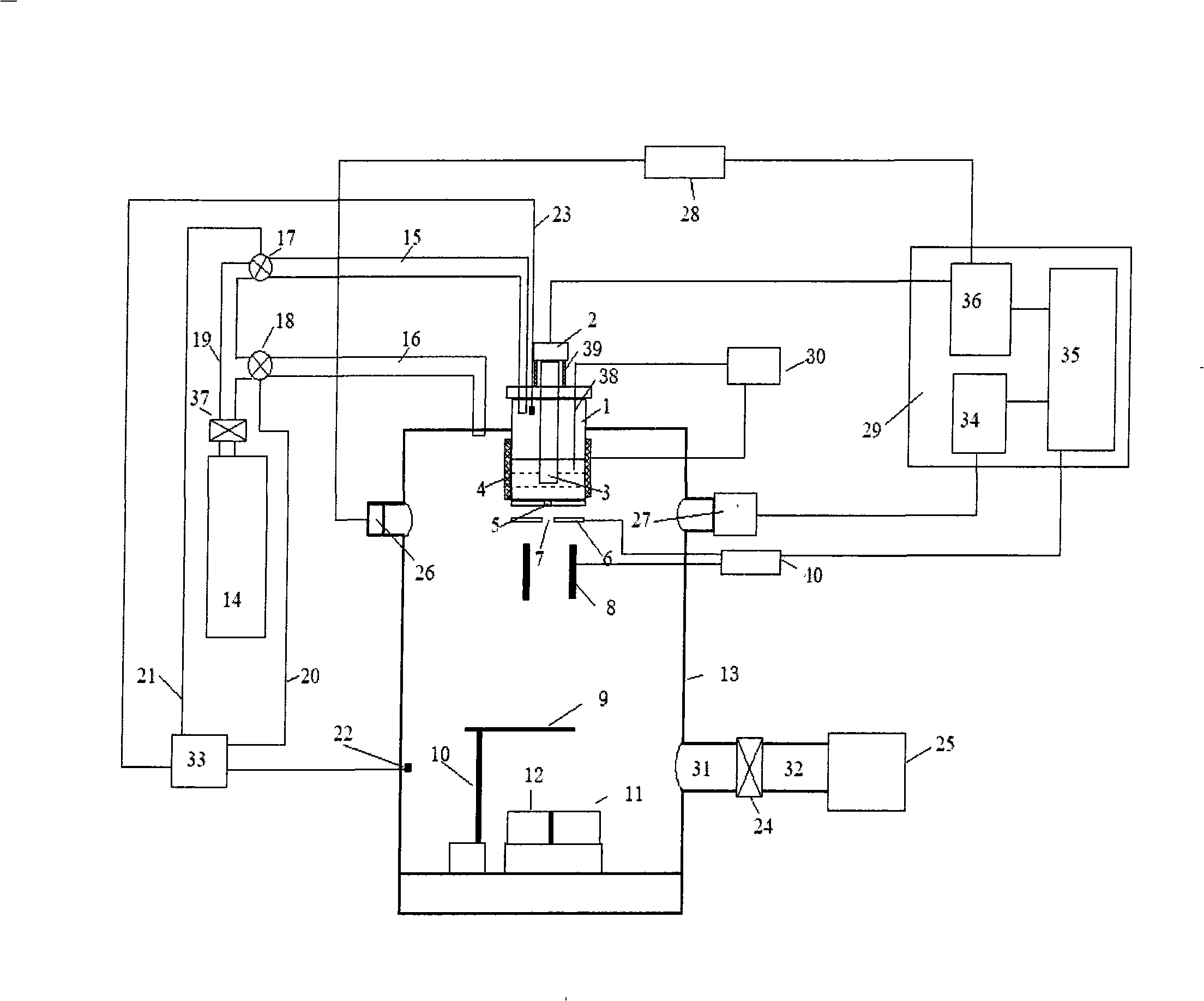

Method and device for preparing micro-uniform grain using harmonic method

A harmonic method and uniform technology, which is applied in the field of micro-particle preparation, can solve problems such as instability and blocked jets of nozzles, and achieve the effect of small size, reduced equipment investment and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Open the crucible loam cake, add the metallic material Sn-3.5Ag-0.5Cu 100g that needs melting in the crucible, and seal;

[0034] (2) Add cooling liquid into the collection device, move the baffle to the top of the collection device, and seal the vacuum chamber;

[0035] (3) vacuumize the crucible and the vacuum chamber, and fill it with nitrogen;

[0036] (4) Heating the crucible, melting the metal material in the crucible, and keeping warm for 20 minutes after the metal material is melted;

[0037] (5) Turn on the piezoelectric oscillator to generate a main frequency of 5KH Z , Harmonic vibration with a frequency ratio of 4, apply a voltage of 250V to the electrode plate, and use the pressure control system to achieve a stable pressure difference of 1.3P between the crucible and the vacuum chamber 0 , so that the molten metal is ejected from the nozzle at the bottom of the crucible in the form of a laminar jet. Under the action of the vibrating head of the piezo...

Embodiment 2

[0042] (1) Open the crucible loam cake, add the metal material Sn-5%Pb that needs melting in the crucible, and seal;

[0043] (2) Add cooling liquid into the collection device, move the baffle to the top of the collection device, and seal the vacuum chamber;

[0044] (3) vacuumize the crucible and the vacuum chamber, and fill it with nitrogen;

[0045] (4) Heating the crucible, melting the metal material in the crucible, and keeping warm for 30 minutes after the metal material is melted;

[0046] (5) Turn on the piezoelectric oscillator to generate a main frequency of 12KH Z Harmonic vibration with a frequency ratio of 2, apply a voltage of 300V to the electrode plate, and use the pressure control system to achieve a stable pressure difference of 1.5P between the crucible and the vacuum chamber 0 , so that the molten metal is ejected from the nozzle at the bottom of the crucible in the form of a laminar jet. Under the action of the vibrating head of the piezoelectric oscilla...

Embodiment 3

[0051] (1) Open the crucible loam cake, add the metallic material Sn-9%Zn that needs melting in the crucible, and seal;

[0052] (2) Add cooling liquid into the collection device, move the baffle to the top of the collection device, and seal the vacuum chamber;

[0053] (3) vacuumize the crucible and the vacuum chamber, and fill it with nitrogen;

[0054] (4) heat the crucible, melt the metal material in the crucible, and keep warm for 25 minutes after the metal material is melted;

[0055] (5) Turn on the piezoelectric oscillator to generate a main frequency of 14KH Z , Harmonic vibration with a frequency ratio of 3, apply a voltage of 300V to the electrode plate, and use the pressure control system to achieve a stable pressure difference of 1P between the crucible and the vacuum chamber 0 , so that the molten metal is ejected from the nozzle at the bottom of the crucible in the form of a laminar jet. Under the action of the vibrating head of the piezoelectric oscillator,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com