Tool for screw mounting operation

A technology for installation and screws, which is applied in the manufacture of tools, screwdrivers, transportation and packaging, etc. It can solve the problems of large-scale structures, inability to simply correspond, and larger devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

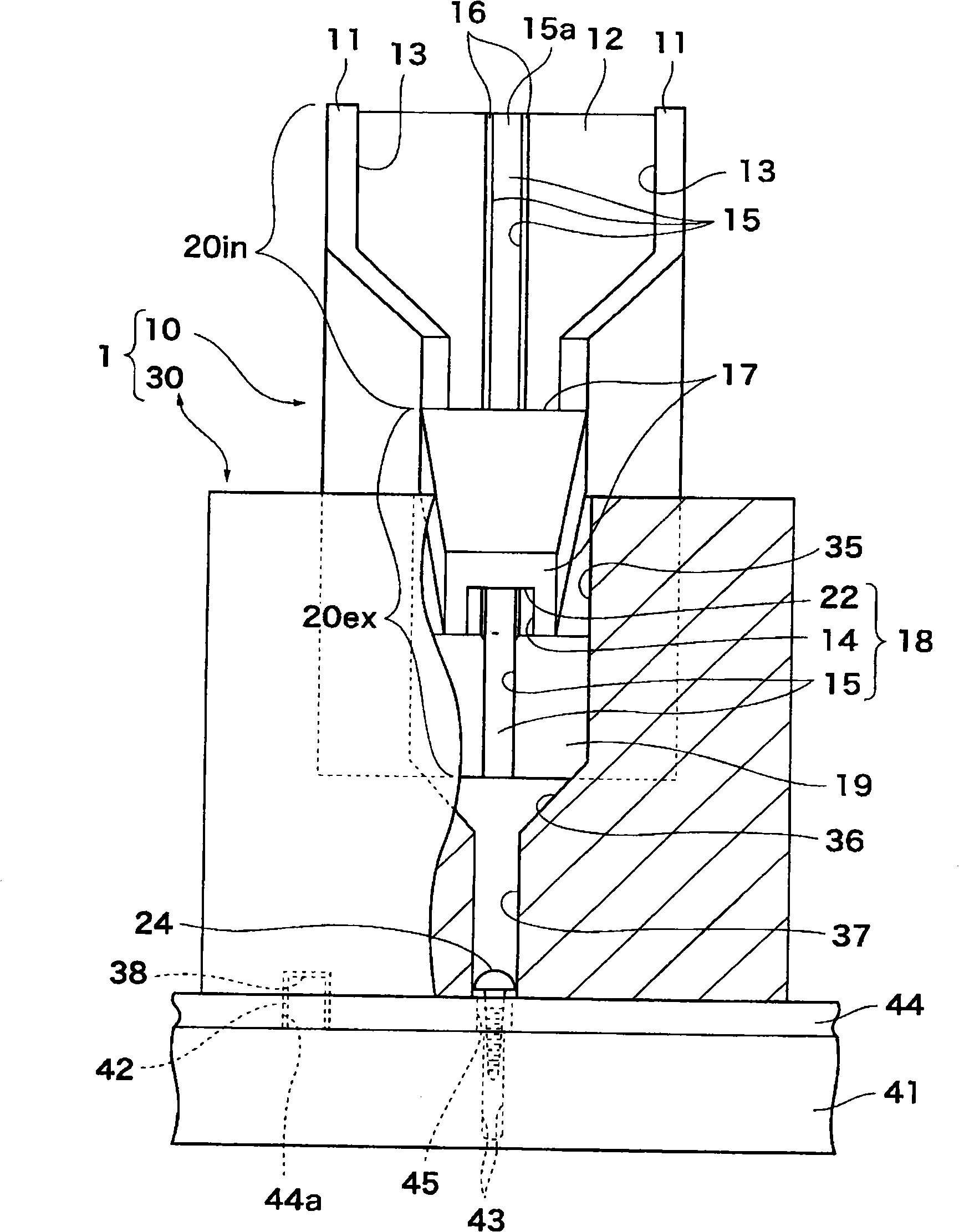

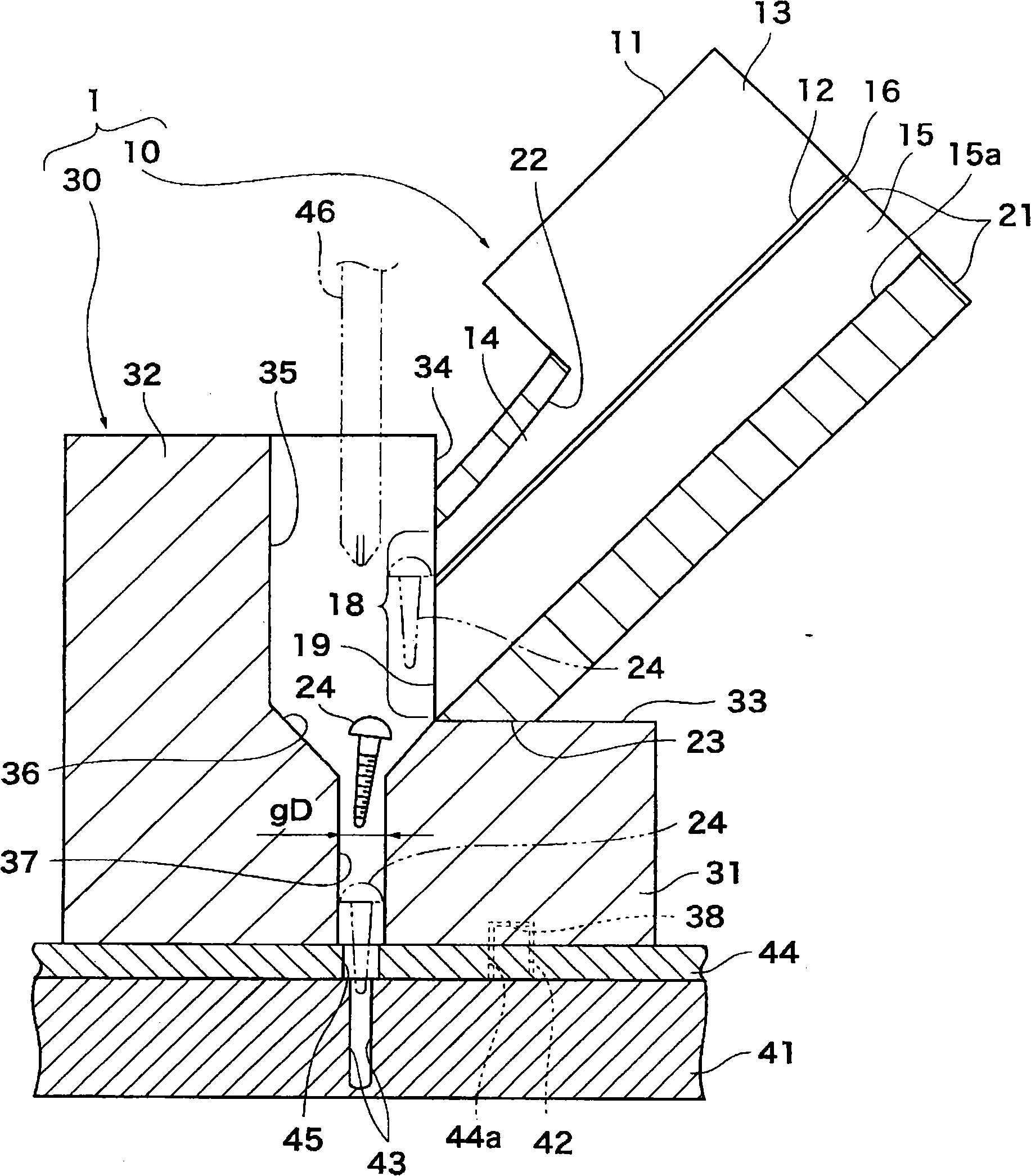

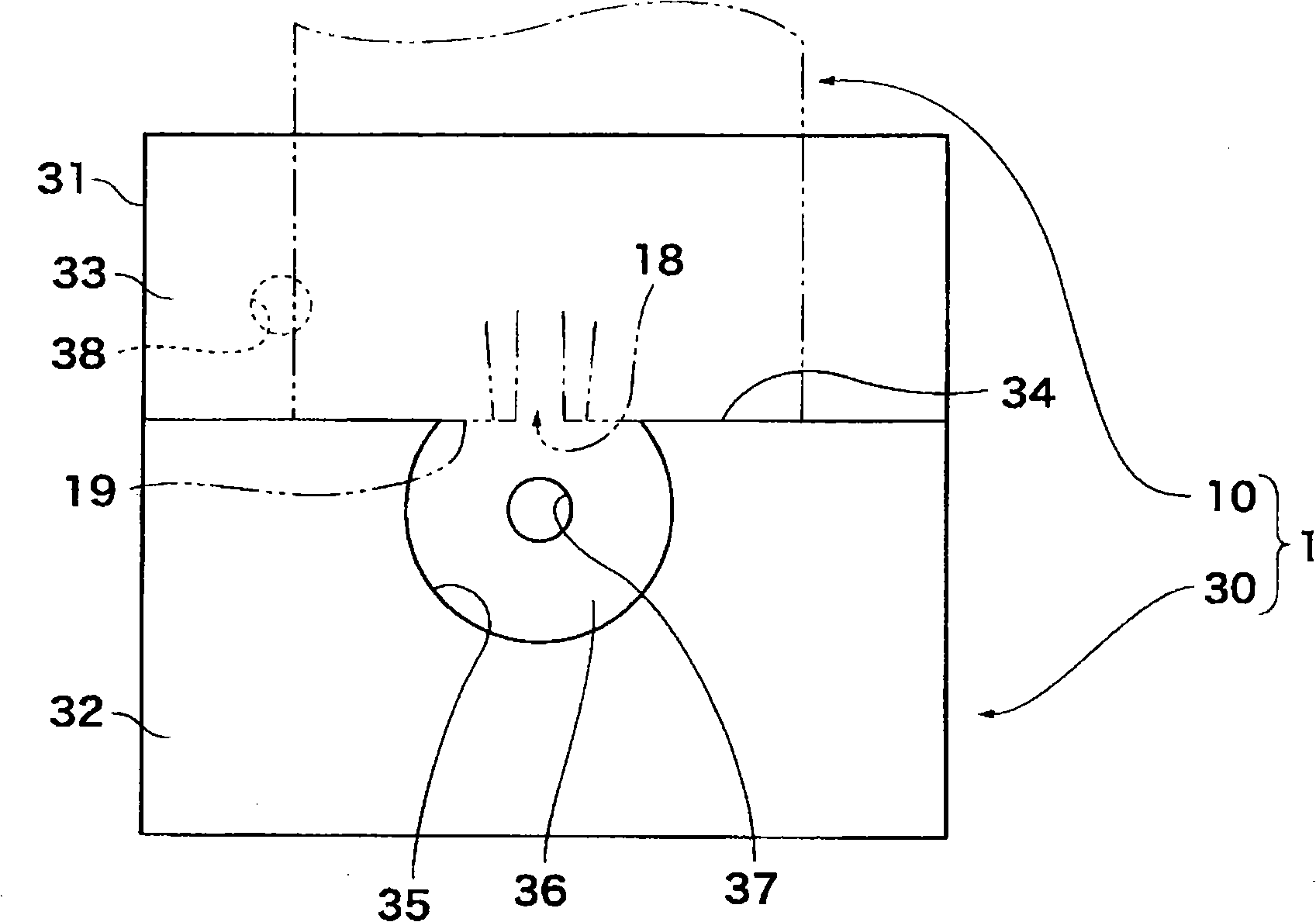

[0029] figure 1 It is a front view of the screw mounting work tool according to one embodiment of the present invention when it is in use. figure 2 It is a front view of the right side when the same screw mounting work tool is used.

[0030] This screw mounting work tool 1 is composed of a main mounting tool 10 and an auxiliary tool 30 . The screw mounting work tool 1 is a simple tool for positioning the screw in a desired connection hole when two members are connected using a screw.

[0031] In this embodiment, the following work is taken as an example. The use of the tool 1 for screw installation work is to facilitate the work of temporarily inserting the screw 24 into the lower hole 43 for connection of the key frame 41 and The state of the connection hole (screw hole) 45 of the key unit 44, and the screw 24 is used to connect and fix the key unit 44 (common base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com