Automatic aligning cloth rolling and measuring machine

A cloth measuring machine and side-rolling technology, which is used in measuring devices, winding strips, textiles and papermaking, etc., can solve the problems of length error, low work efficiency, wrinkles, etc., and achieve accurate measurement, high work efficiency, and cloth measuring. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

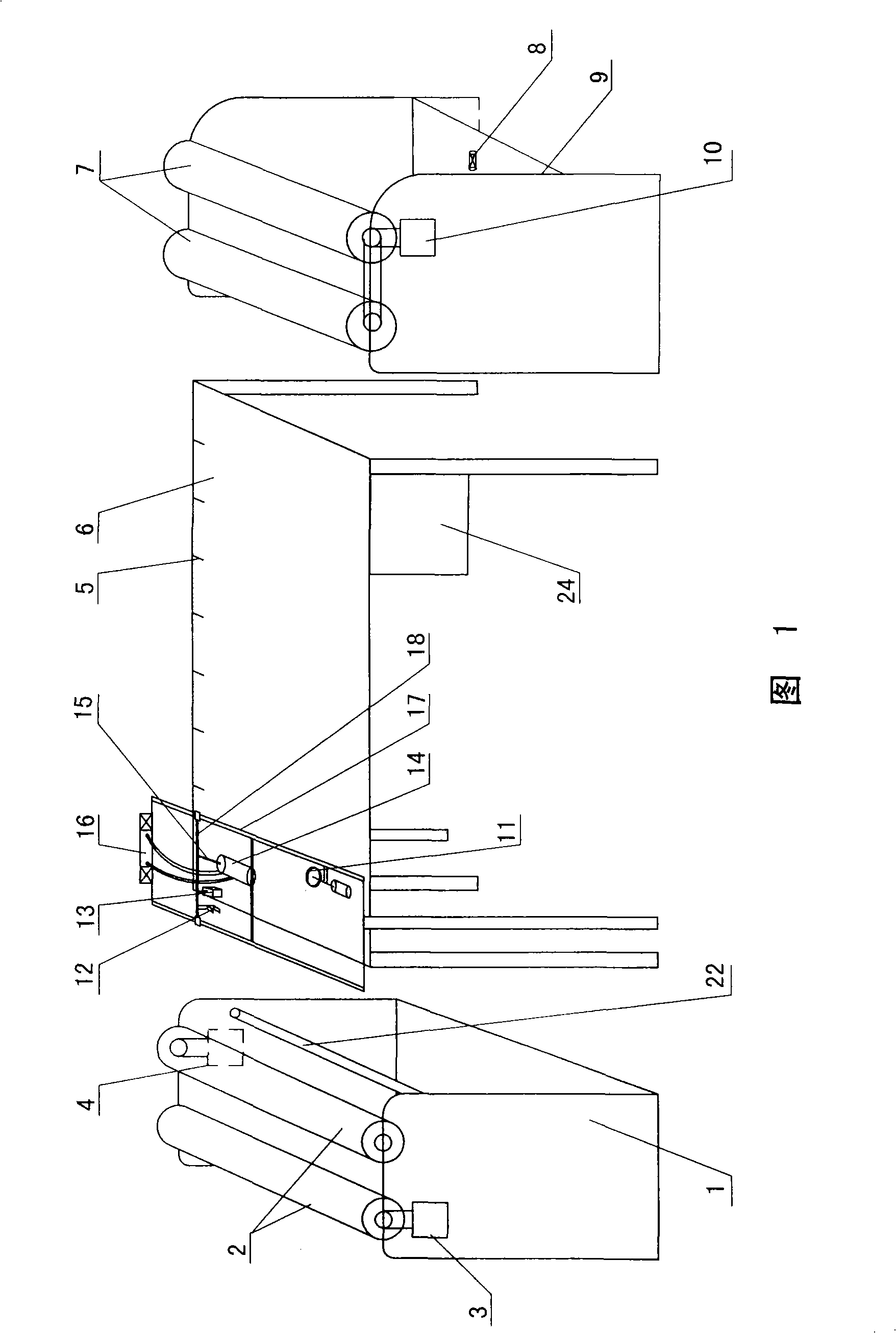

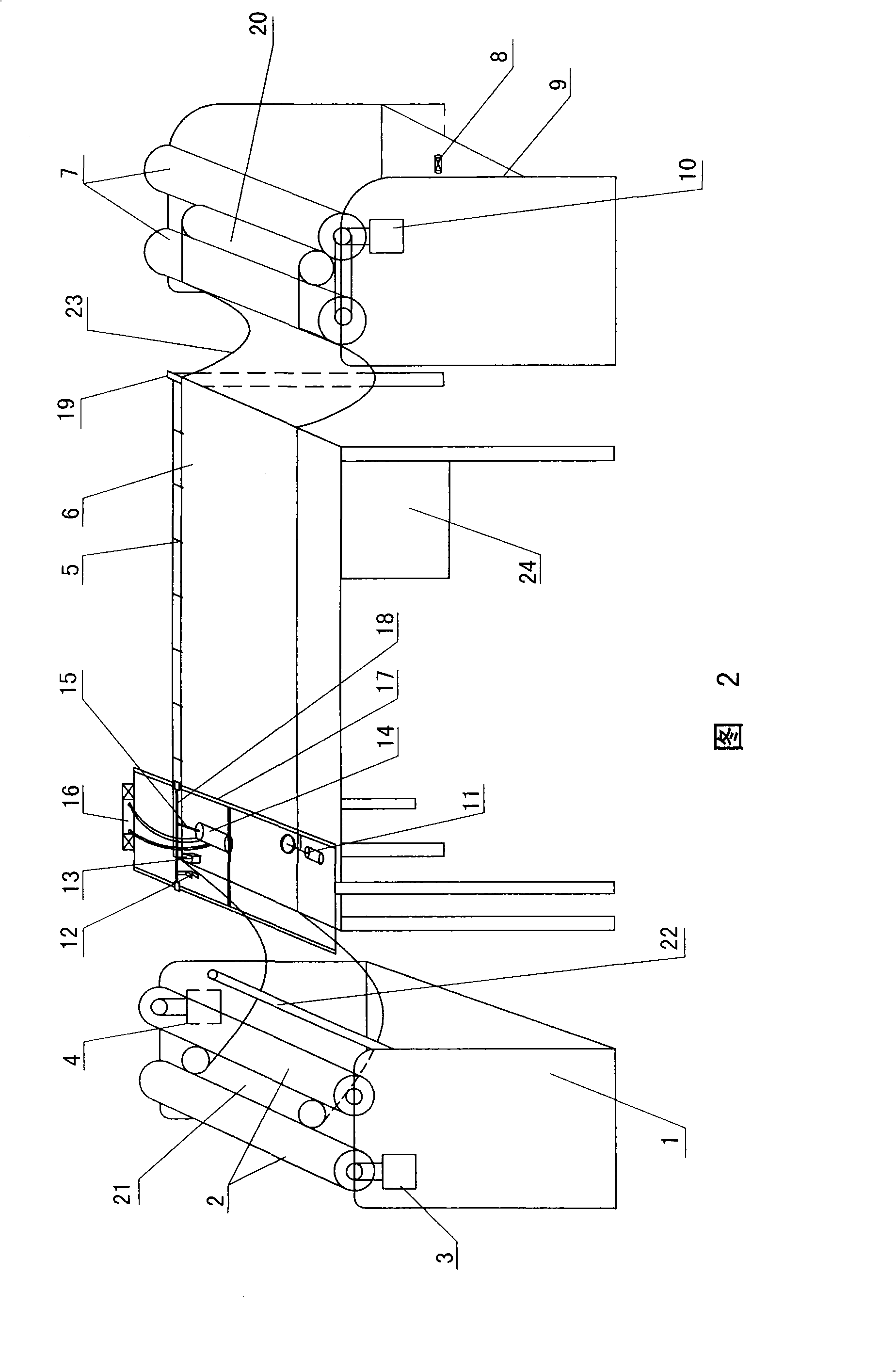

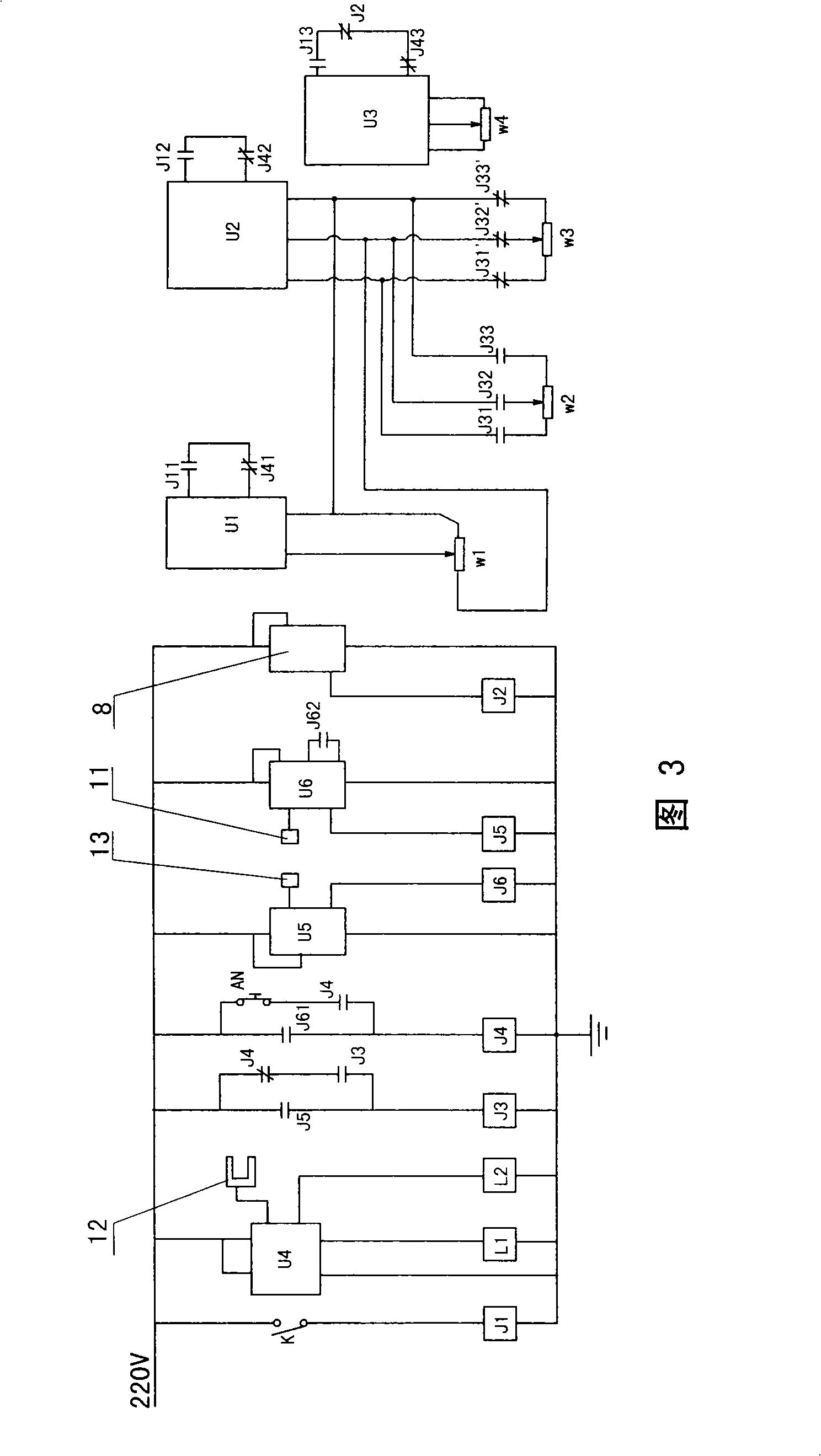

[0020] 1. Cloth rolling device 2, cloth rolling roller 3, 4, motor 5, scale 6, cloth measuring table 7, cloth feeding roller 8, photoelectric switch 9, frame 10, motor 11, speed measuring wheel 12, edge detector 13, Photoelectric sensor 14, cylinder 15, piston 16, two-way solenoid valve 17, bracket 18, cross bar 19, reflective label 20, cloth roll to be tested 21, reel 22, cloth guide roller 23, cloth 24, control box

[0021] In the embodiment shown in Figures 1-2: two parallel cloth feed rollers 7 bearings are installed on the frame 9, connected by chain transmission, the output shaft of the motor 10 is fixedly connected with the active cloth feed roller 7, the model is GJ - The photoelectric switch 8 of 2M-B is installed on the frame 9 and located below the cloth feed roller 7, the cloth feed roller 7 and the two cloth rolls 2 in the cloth roll device 1 are parallel and separated from the scale 5 on the cloth case 6 ends. The cloth roll 20 to be tested is placed between the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap