Fault injection system and method for verifying anti-single particle effect capability

An anti-single event effect and fault injection technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as high requirements for software and hardware equipment, unfavorable automation, non-uniform random selection, etc., to improve computing Speed, increased versatility, and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

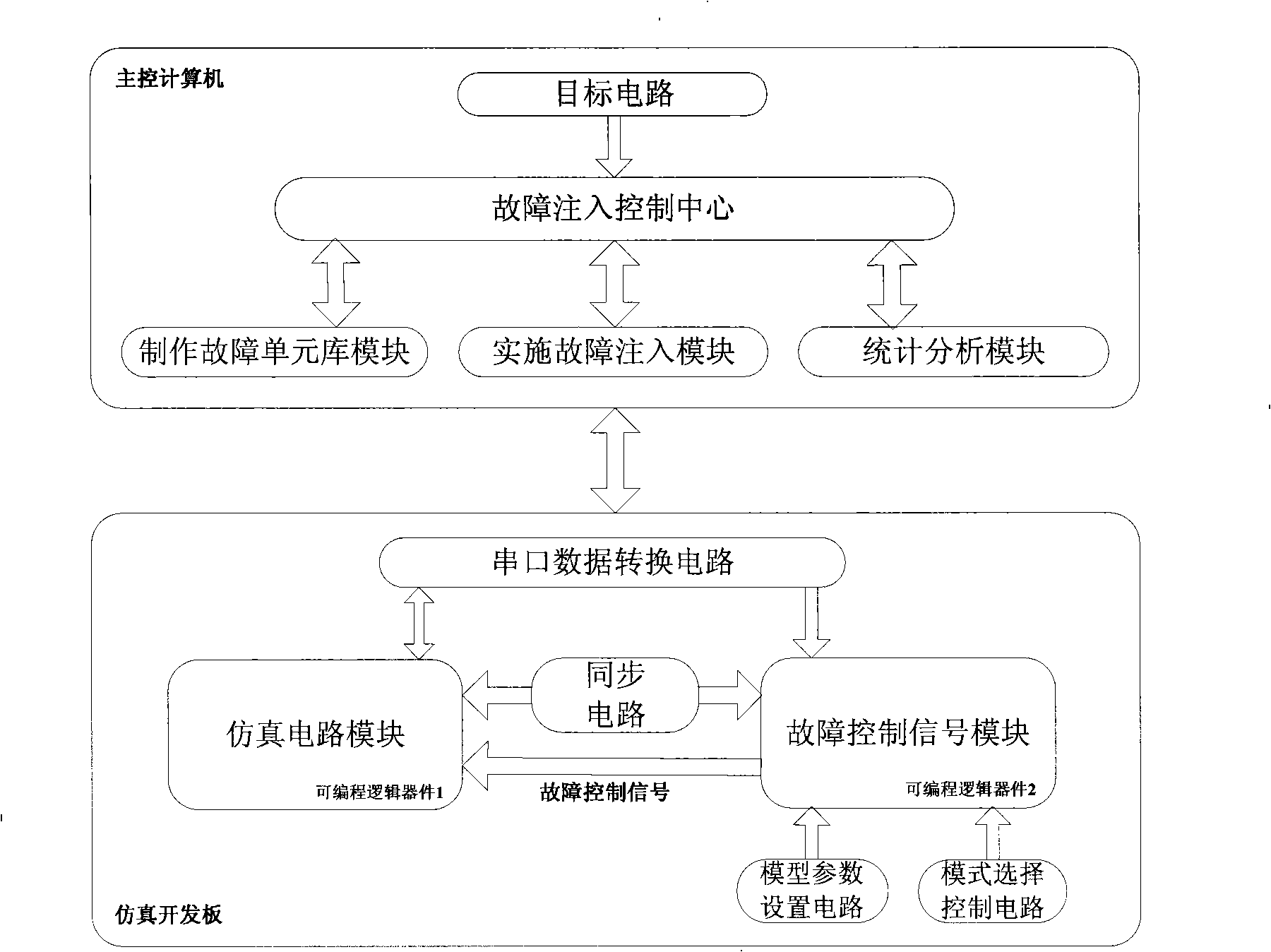

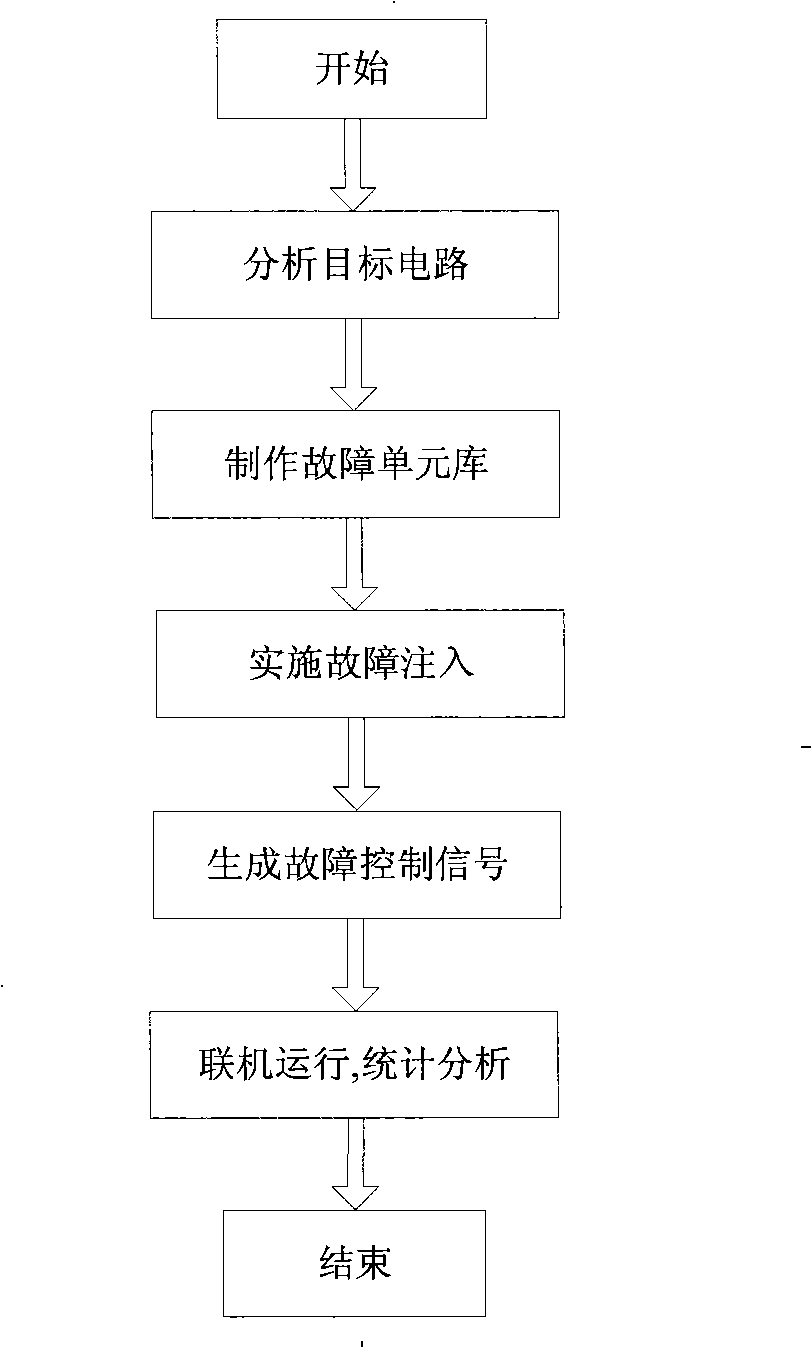

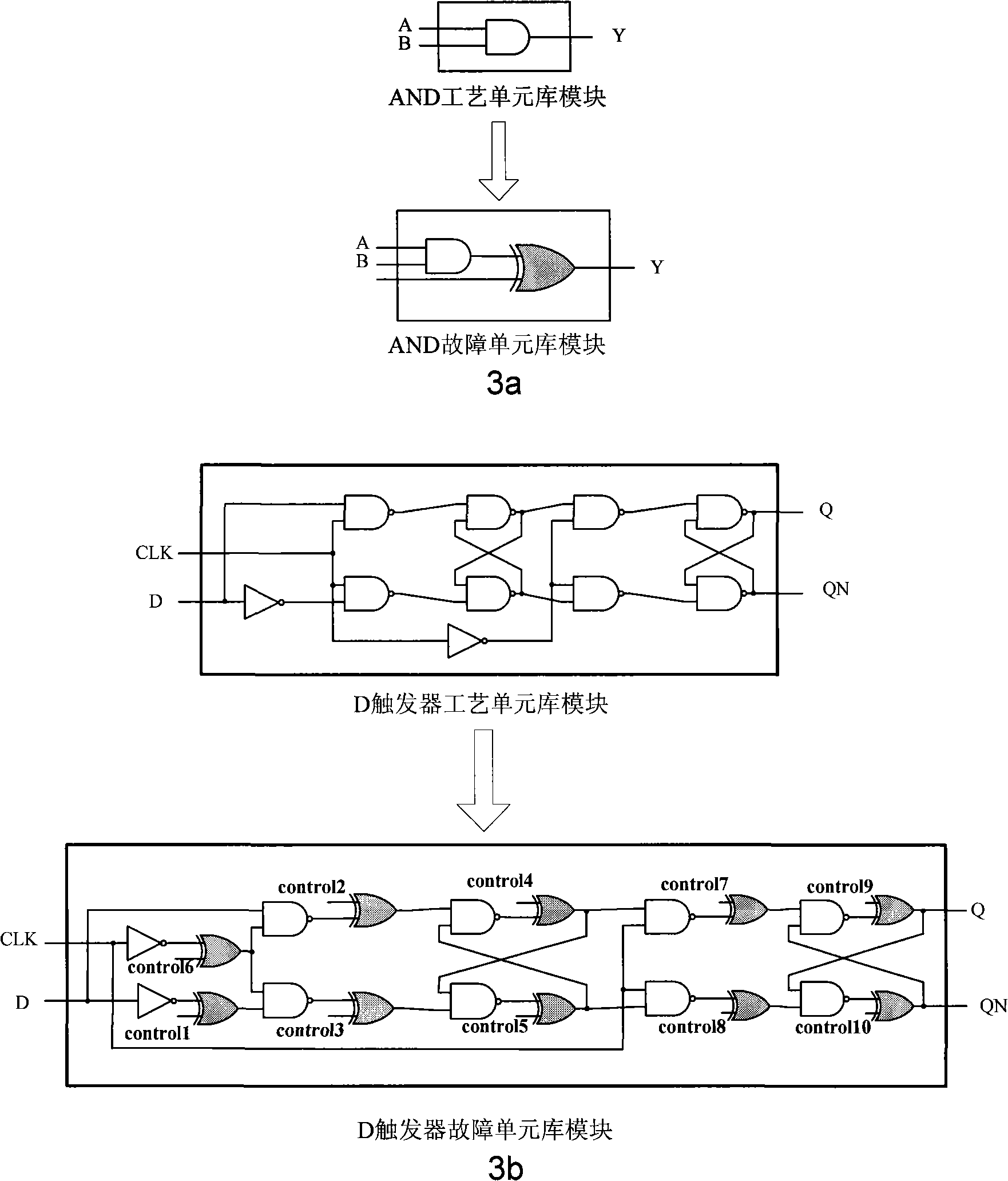

[0062] Such as figure 1 A structural schematic diagram of the fault injection system for verifying the single event effect of the present invention is illustrated. The system of the present invention includes making a fault unit library module, implementing a fault injection module, a statistical analysis module, a synchronous circuit, a simulation circuit module and a fault control signal module; the main control computer contains a fault injection control center, making a fault cell library module, and implementing fault injection Module, statistical analysis module, the main control computer is connected with the simulation circuit module and the fault control signal module through the serial port data conversion circuit, the serial port data conversion circuit is RS232 serial port circuit, USB transmission circuit, network cable transmission circuit, etc., the model parameter setting circuit is multi-bit The dial switch circuit is connected to the input terminal of the fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com