Training apparatus for chemical industry production

A technology of chemical production and training equipment, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problems of high operating costs, inability to obtain operational skills, and limited practical operation ability, and achieve the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

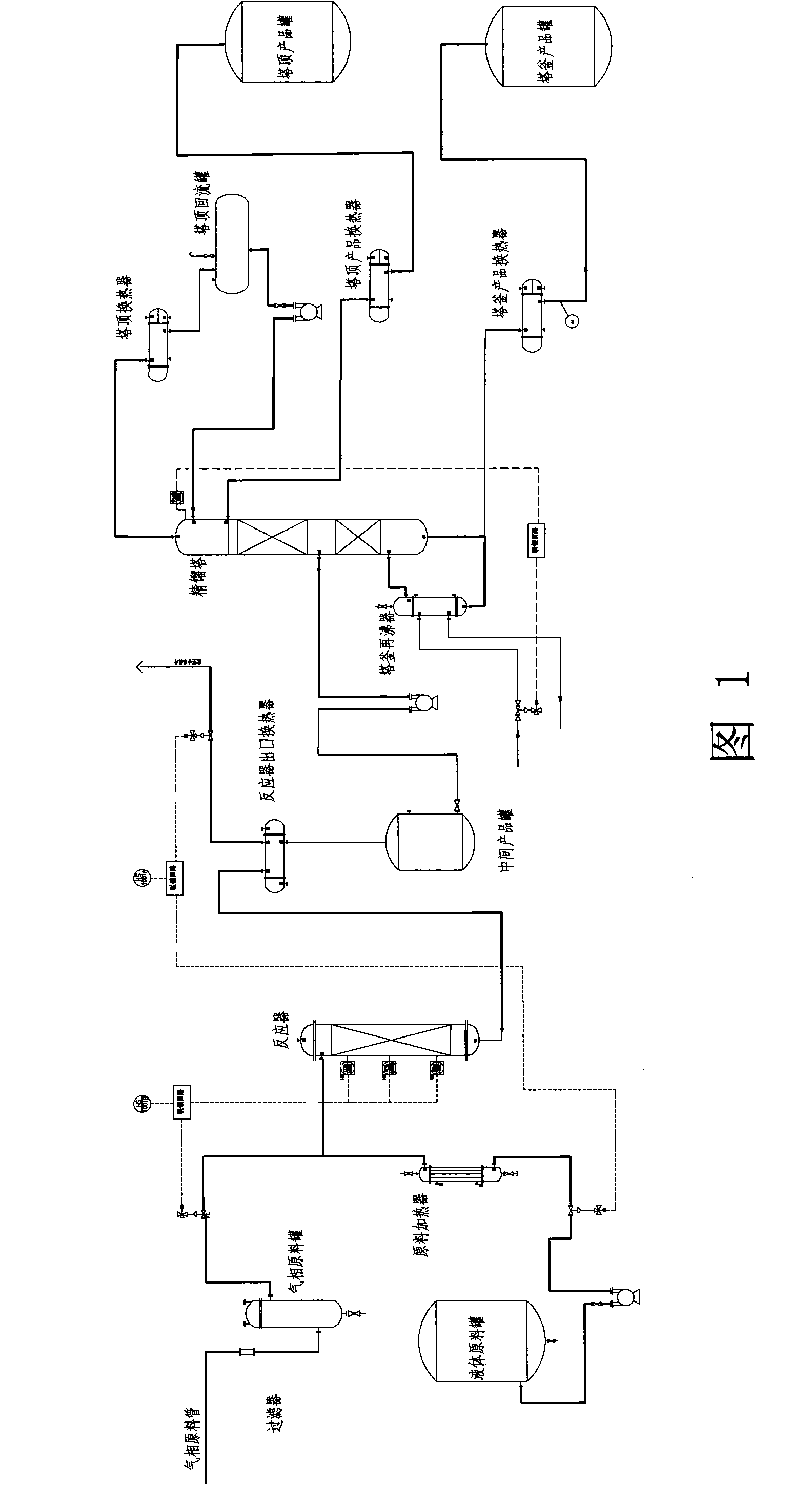

[0035] (1) Training device for ethylene production

[0036] The device includes a reaction unit, a separation unit and a matching storage tank system.

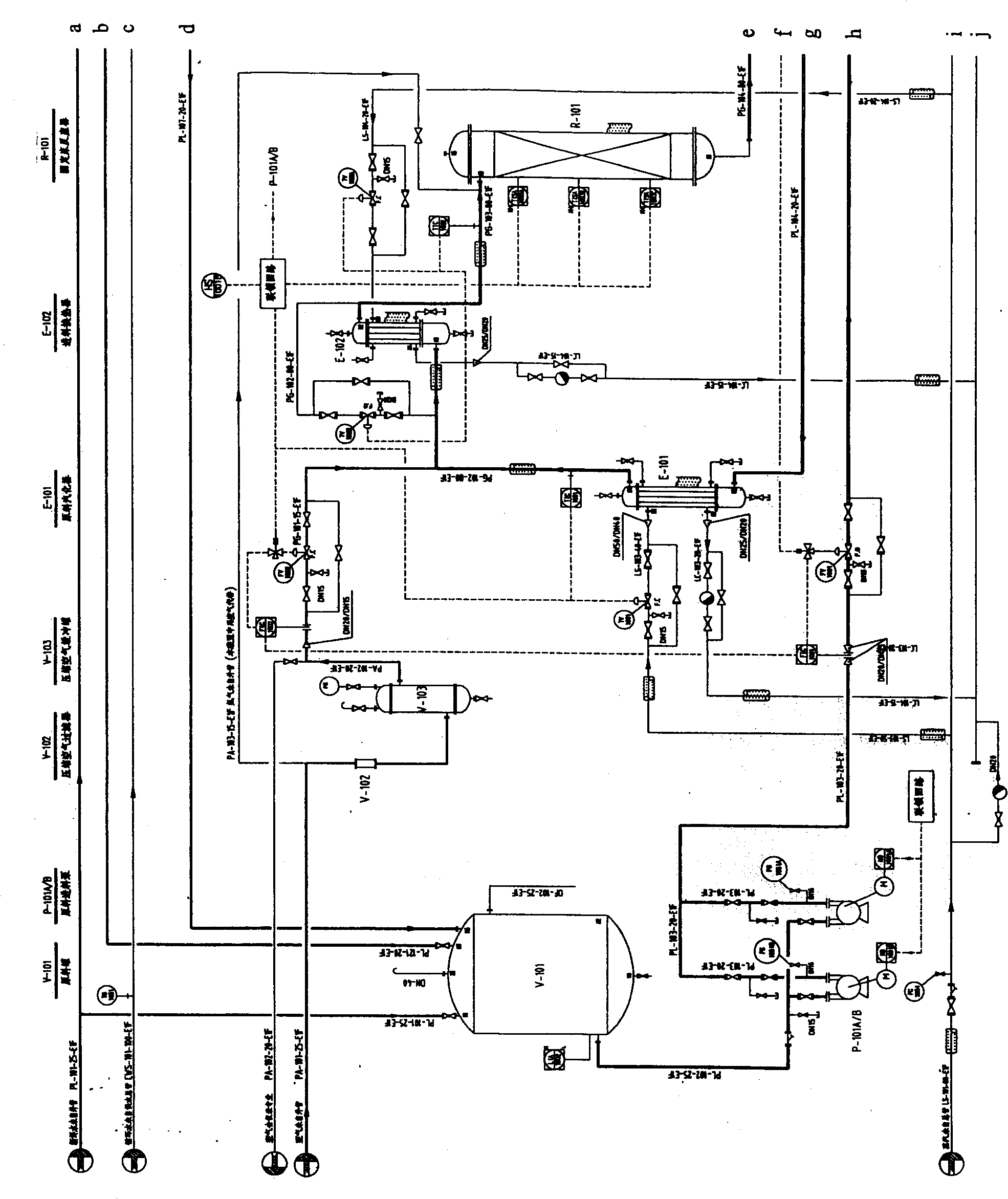

[0037] Among them, the reaction unit includes air purification, raw material vaporization, hydrogenation reactor, condensation and collection of products. The separation unit includes a rectification column, a reflux tank, a tower top condenser, and a tower kettle reboiler. The storage tank system includes raw material tanks, tower top product tanks, and tower still product tanks. The material (water) in the raw material tank V-101 is transported by the pump P101A / B, vaporized by the E101 vaporizer, mixed with air, and then enters the fixed bed reactor R101. After being condensed by the E103 condenser, the material at the outlet of the reactor enters the reaction product storage tank V104, and the non-condensable gas enters the vent pipe.

[0038]The liquid in V104 enters the middle part of the T201 rectification column con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com