Organic light emitting display

一种发光显示器、有机的技术,应用在静态指示器、电致发光光源、仪器等方向,能够解决产品可靠性降低、检测到等问题,达到高可靠性、降低模块工艺成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0046] It should be understood that an electrical connection between a certain element and another element includes a direct electrical connection between them and an indirect electrical connection between them through an intervening element.

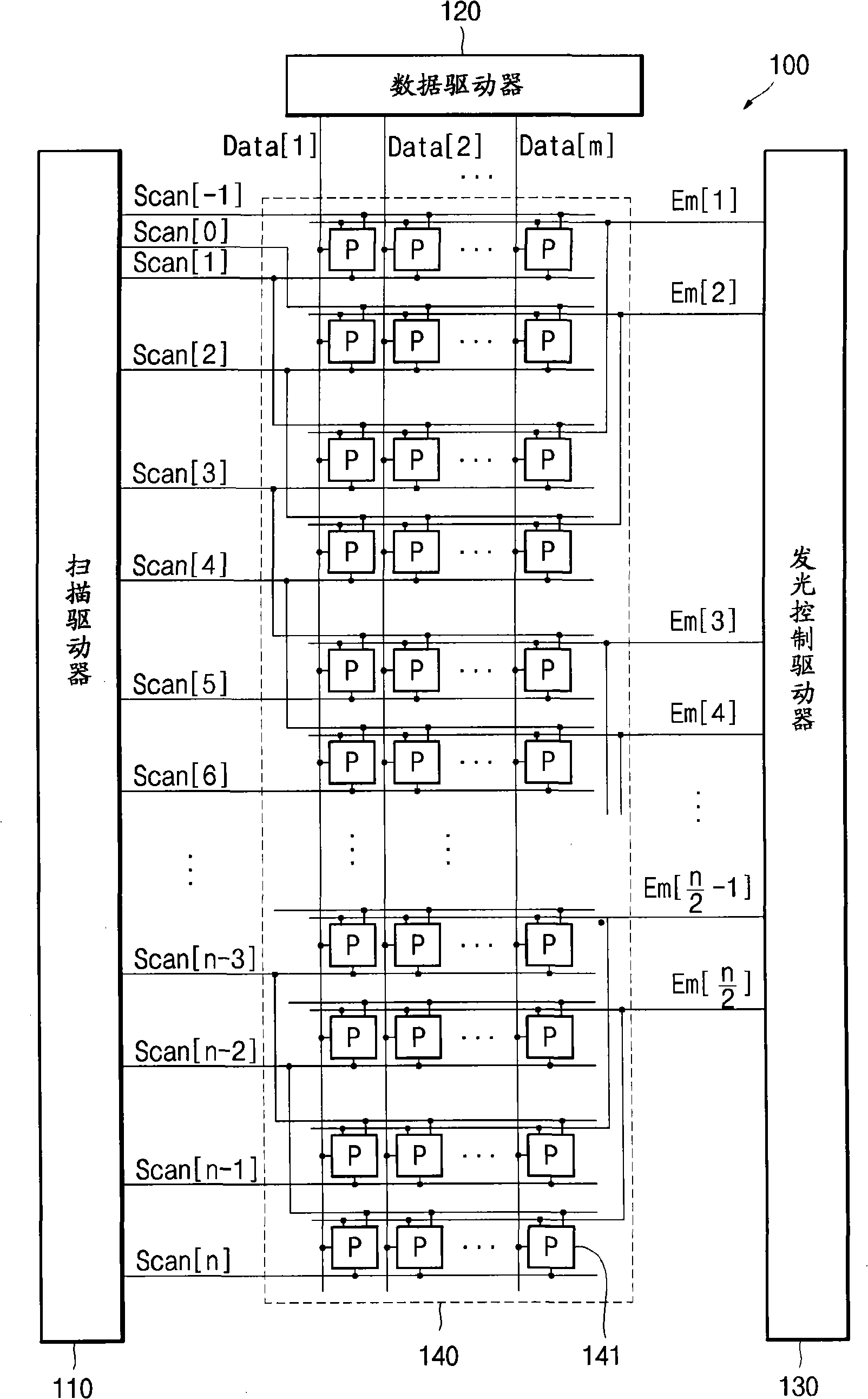

[0047] figure 1 A schematic block diagram of an organic light emitting display according to an exemplary embodiment of the present invention is shown.

[0048] Such as figure 1 As shown in , an organic light emitting display 100 in an exemplary embodiment includes a scan driver 110 , a data driver 120 , an emission control driver 130 and an organic light emitting display panel (hereinafter, referred to as a “panel”) 140 .

[0049] The scan driver 110 may sequentially provide scan signals to the panel 140 through a plurality of scan lines (Scan[−1], Scan[0], Scan[1], Scan[2], . . . , Scan[n]).

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com