Brushless double-mechanical-port motor

A dual mechanical port and end face technology, applied in the direction of electromechanical devices, electrical components, magnetic circuit static parts, etc., can solve the problems that the inner rotor is difficult to dissipate heat, the number of phases cannot be different from the expansion of two phases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

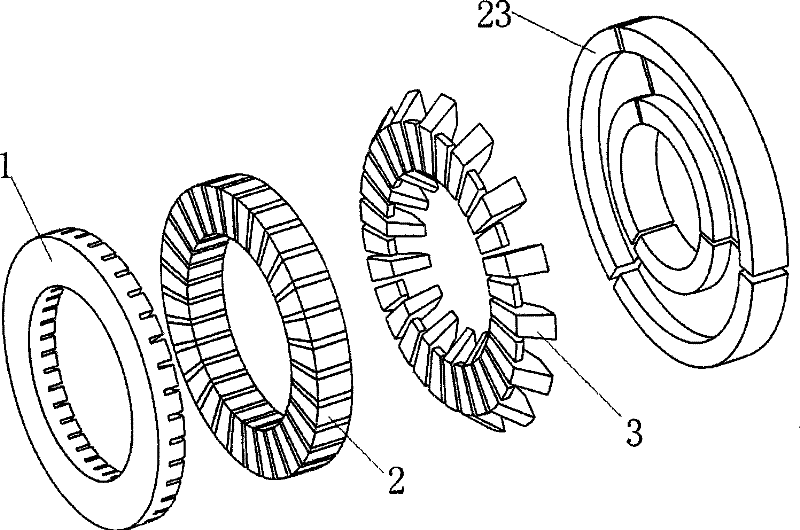

[0022] A specific implementation of the dual mechanical port motor of the present invention is as follows: figure 1 As shown, this is a disc motor with axial flux, mainly composed of four components with a disc structure, which are the first stator 1, the first rotor 2, the second stator 23 and the second rotor in sequence 3. After assembly and molding, the two stators 1, 23 are located on the outer side, and the two rotors 2, 3 are located on the inner side of the two stators 1, 23, such as Figure 7 shown. Wherein, the second rotor 3 is connected with the output shaft 25 of the engine, and the first rotor 2 is connected with the drive shaft 26 of the vehicle. There is no mechanical connection between the two rotors 2 , 3 , and they are electromagnetically coupled entirely by the electromagnetic field in the second air gap 18 .

[0023] Assuming that the engine output speed is n1, the torque is T1, the output shaft speed is n2, and the torque is T2, the current frequency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com