High pressure cleaning machine and uses thereof

A high-pressure cleaning machine and high-pressure technology are applied to cleaning methods and appliances, cleaning methods using liquids, cleaning methods using gas flow, etc., which can solve the problems of inconvenient maintenance, large equipment, and high energy consumption of equipment, and achieve reduction Maintenance time, effect of eliminating noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

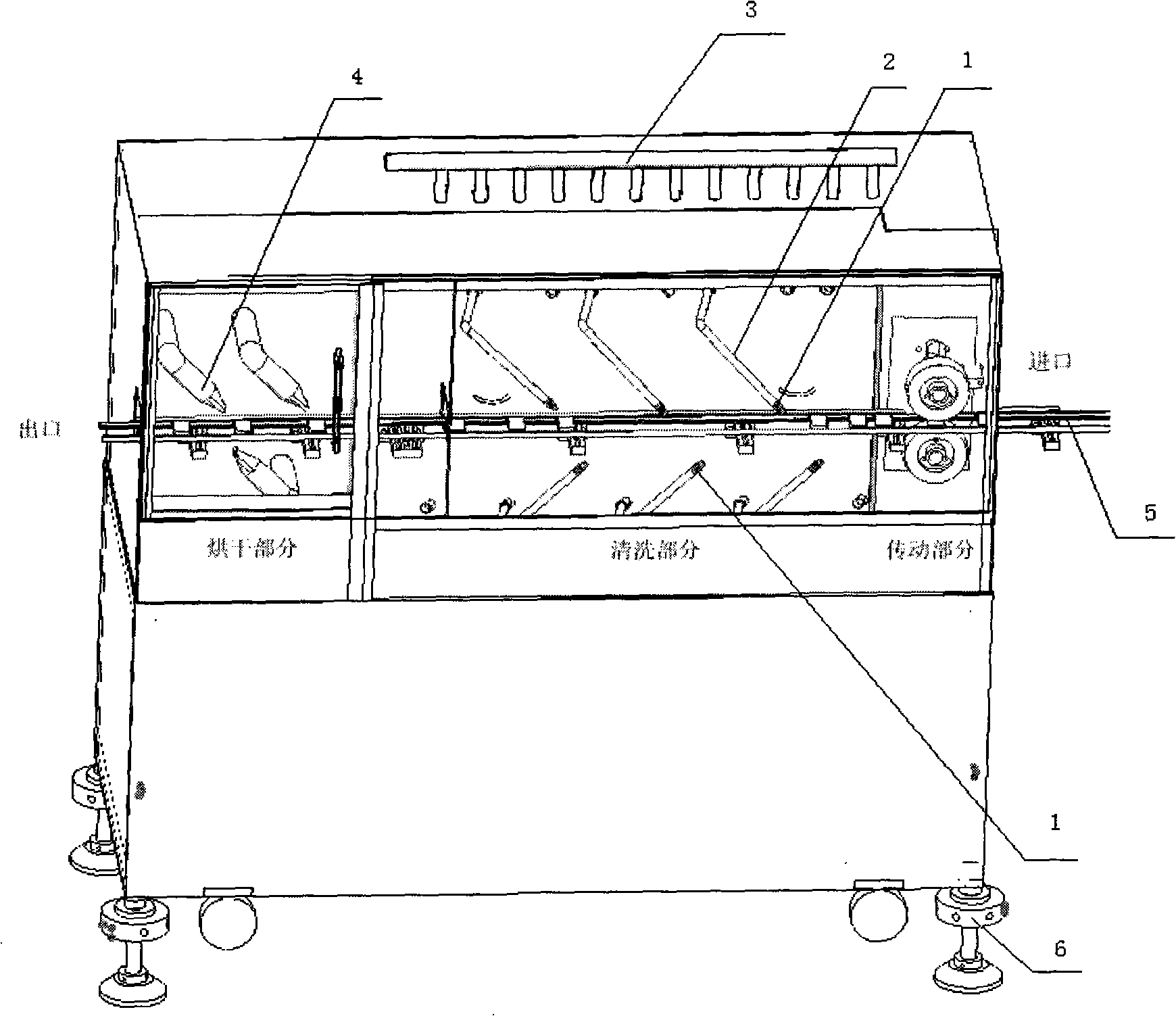

[0027] The high-pressure cleaning machine will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] In this example, the device being cleaned is a ferrite magnetic material.

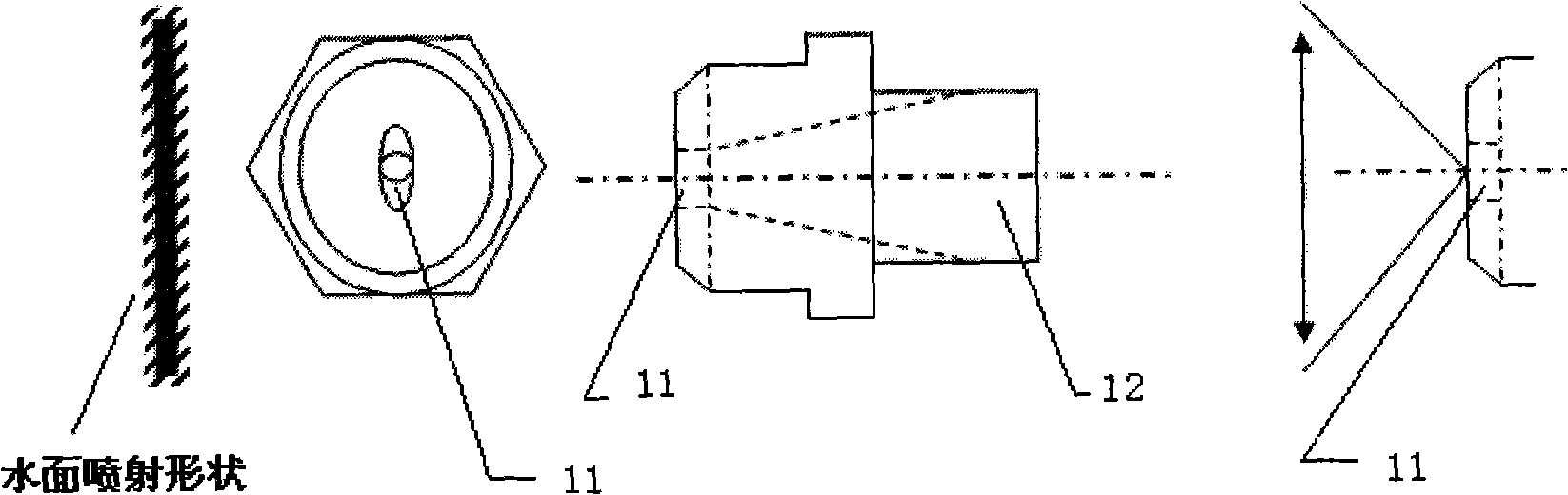

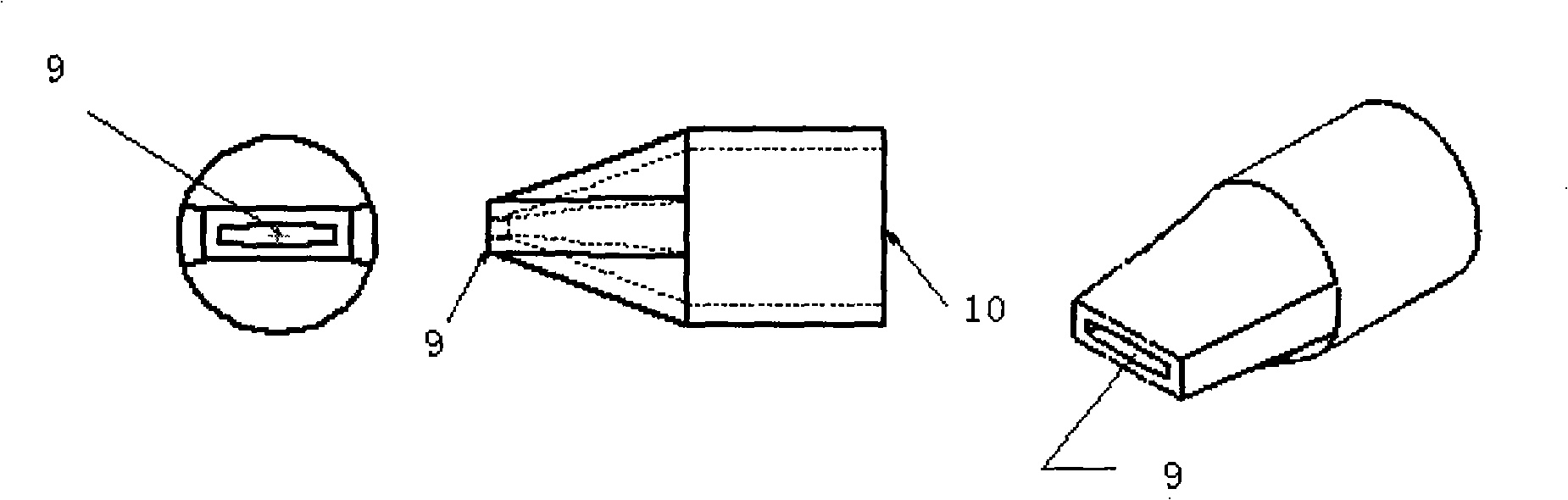

[0029] A high-pressure cleaning machine includes a body, a cleaning part, and a transmission part, and the cleaning part and the transmission part are arranged in the body. The cleaning part includes a spray nozzle and a water pump; the water inlet of the spray nozzle is connected to the water outlet of the water pump through a pipeline; the output water pressure of the water pump is 1Mpa; the sprayed water surface of the water outlet of the spray nozzle is a fan-shaped fog liquid surface; the high-pressure fan-shaped fog liquid The water surface forms a water jet; the spray nozzle is arranged beside the position of the transmission part.

[0030] The transmission part includes a conveying guide rail, a push roller, and a motor; there are two push r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com