Special anchorage for combined variable-corrugated fiber sheets and prestressing force stretching method thereof

A fiber sheet and combined technology, applied in the processing of building materials, structural elements, building components, etc., can solve problems such as difficulties, insufficient anchoring technology, damage to fiber sheets, etc., and achieve high strength utilization and wide application range , The effect of uniform clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

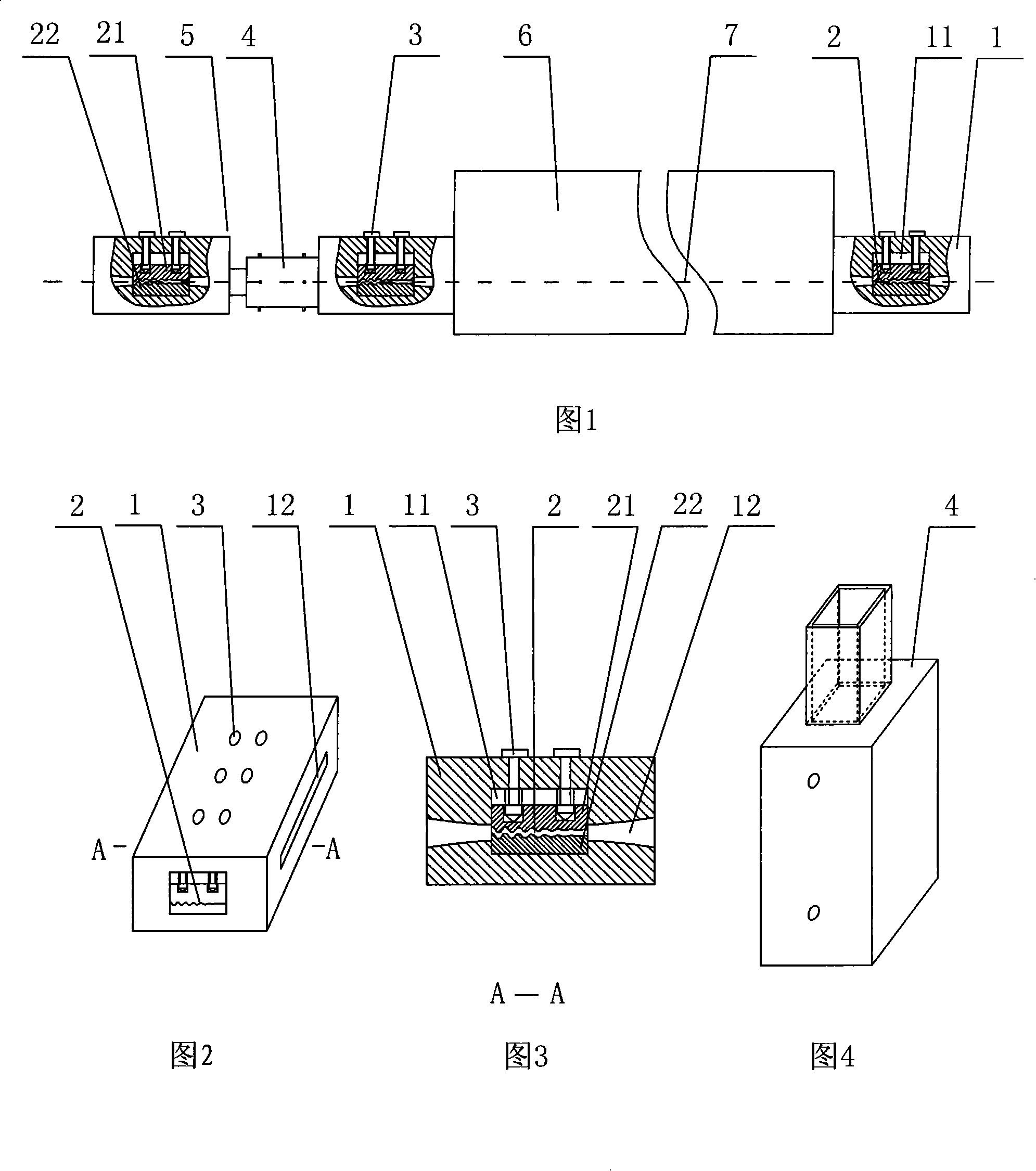

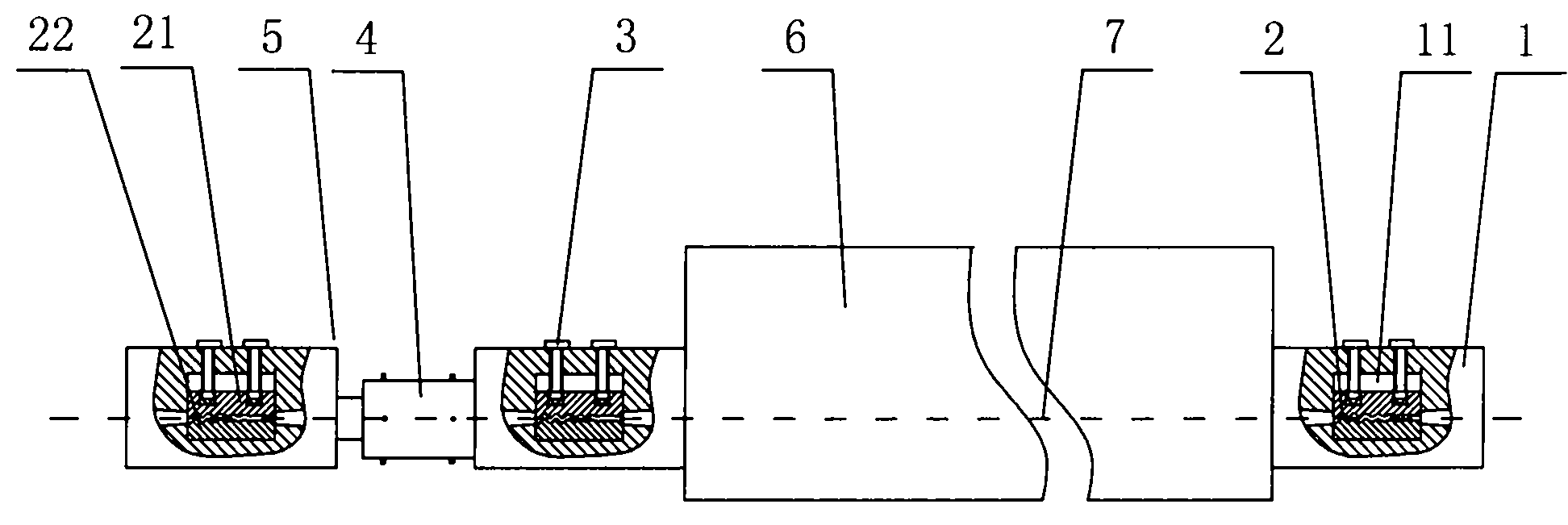

[0033] See attached Figure 1-4 , the combined variable corrugated fiber sheet special anchorage of the present invention, it comprises outer anchor shell 1, variable corrugation clip 2, pressure bolt 3, and its outer anchor shell 1 is longitudinally provided with locking square hole 11, and locking square hole 11 is provided with a variable corrugated clip 2 including an upper corrugated clip 21 and a lower corrugated clip 22, and more than three sets of pressure bolts 3 are arranged on the top of the locking square hole 11 of the outer anchor shell 1, and the pressure bolts 3 pass through the locking square hole. The corresponding bolt holes on the top of 11 fix the upper corrugated clip 21 movably and hang on the upper top of the locking square hole 11 of the outer anchor shell 1, and the lower corrugated clip 22 is fixed on the bottom of the locking square hole 11. A penetrating flat hole 12 is arranged in the outer anchor shell 1 perpendicular to the locking square hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com