Ceramic plunger

A technology of ceramic plunger and top ring, which is applied to the components of pumping devices for elastic fluids, variable displacement pump components, machines/engines, etc. The effect of reducing the longitudinal impulse

Inactive Publication Date: 2008-10-15

ANTON OILFIELD SERVICES (GRP) LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention provides a ceramic plunger with high temperature resistance, corrosion resistance and good stability in order to overcome the stuck problem of the oil pump existing in the prior art due to thermal deformation of the metal plunger.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Login to View More

Abstract

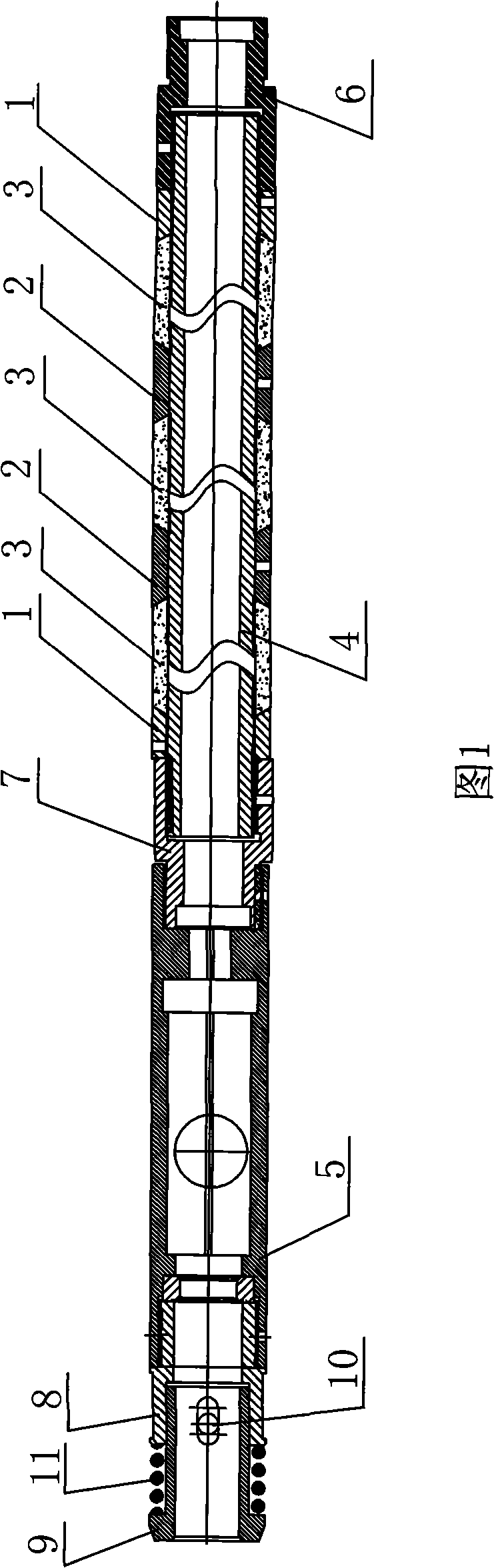

The invention relates to the oilfield oil extraction equipment manufacturing technical field, in particular to a ceramic plunger. To overcome the problem of blockage of an oil pump in the prior art caused by the heating and deformation of a metal plunger, the invention provides the ceramic plunger which comprises a top ring, a spacing ring, a ceramic plunger barrel, an oil pumping pipe and a ball valve; one end of the top ring has a sunken conical surface; two ends of the ceramic plunger barrel have protuberant ceramic conical surfaces, two ends of the spacing ring have sunken conical surfaces; one end of the ball valve is fixedly connected with a middle check nut; the other end of the ball valve is provided with a spring seat; the spring seat is provided with a spring seat liner inside; the spring seat is connected with the spring seat liner by a spring seat pin; and a spring is arranged between the spring seat and the spring seat liner. The ceramic plunger lightens the vertical impulsive force when the plunger bumps the pump, eliminates the extrusion to the ceramic plunger barrel when the metal top ring, the spacing ring and the oil pumping pipe are heated and expanded, and protects the ceramic plunger barrel from being broken easily.

Description

A ceramic plunger technical field The invention relates to the technical field of manufacturing oil field oil extraction equipment, in particular to a ceramic plunger. Background technique The oil well pump is one of the main equipment in the oil well production system, and the plunger is the key component of the oil well pump. In the process of using the oil well pump to produce oil in the existing heavy oil steam flooding well, the metal plunger is thermally deformed and the pump is stuck, which affects Oil well production. Although the plunger made of ceramic materials has excellent high temperature resistance, high chemical stability and wear resistance, ceramics are brittle and easily broken and damaged, so special structural design is required to meet the actual production requirements. need. Contents of the invention The present invention provides a ceramic plunger with high temperature resistance, corrosion resistance and good stability in order to overcome th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04B53/14

Inventor 李耀辉于海李罡代圣

Owner ANTON OILFIELD SERVICES (GRP) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com