Heat exchange tube of fat and oil processing equipment

A technology for oil processing and heat exchange tubes, applied in the field of heat exchange tubes, can solve problems affecting product quality and heat exchange efficiency, and achieve the effects of reducing residual amount, improving heat exchange efficiency, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

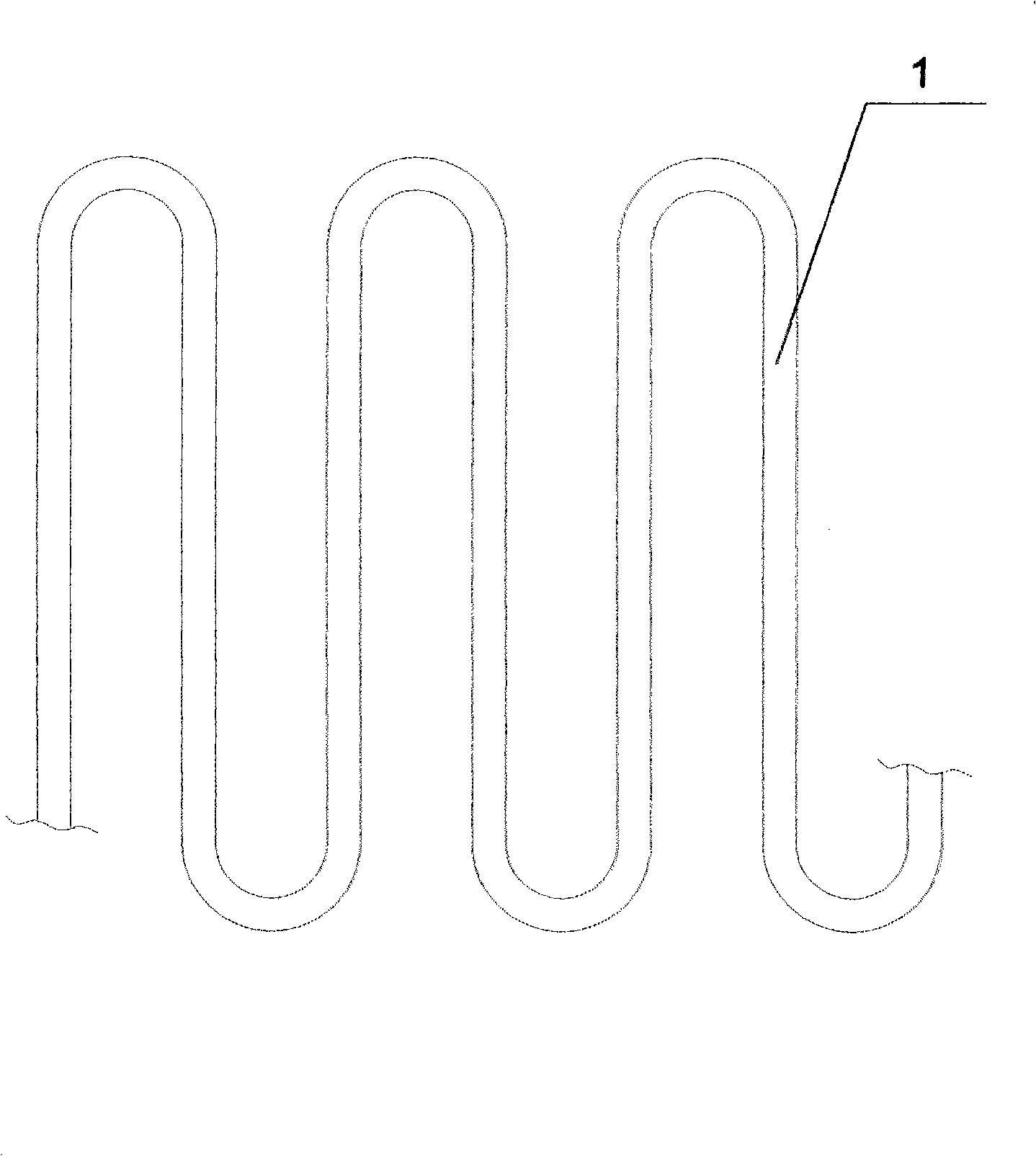

[0008] refer to figure 1 , the heat exchange tube 1 is arranged in the oil processing equipment, and it is in the shape of a continuous U-shaped vertical arrangement. In this process, only a small amount of deposition will be produced on the plane where the U-shaped turns of the heat exchange tube 1 meet, thereby greatly reducing the residual amount in the processing process, achieving the effect of sufficient separation, effectively improving product quality, and helping to improve the exchange rate. Thermal efficiency.

[0009] In addition, the above-mentioned heat exchange tubes 1 can be arranged in the oil processing equipment in a regular or irregular manner such as round shape, linear shape, and square shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com