On-line measurement digital sensing device for grain depot foodstuffs temperature and moisture

A sensing device and grain technology, applied in the digital sensing device of moisture, in the field of online measurement of grain temperature in grain depots, can solve the problem of not being able to accurately measure grain temperature and moisture online at the same time, and achieve low production cost and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

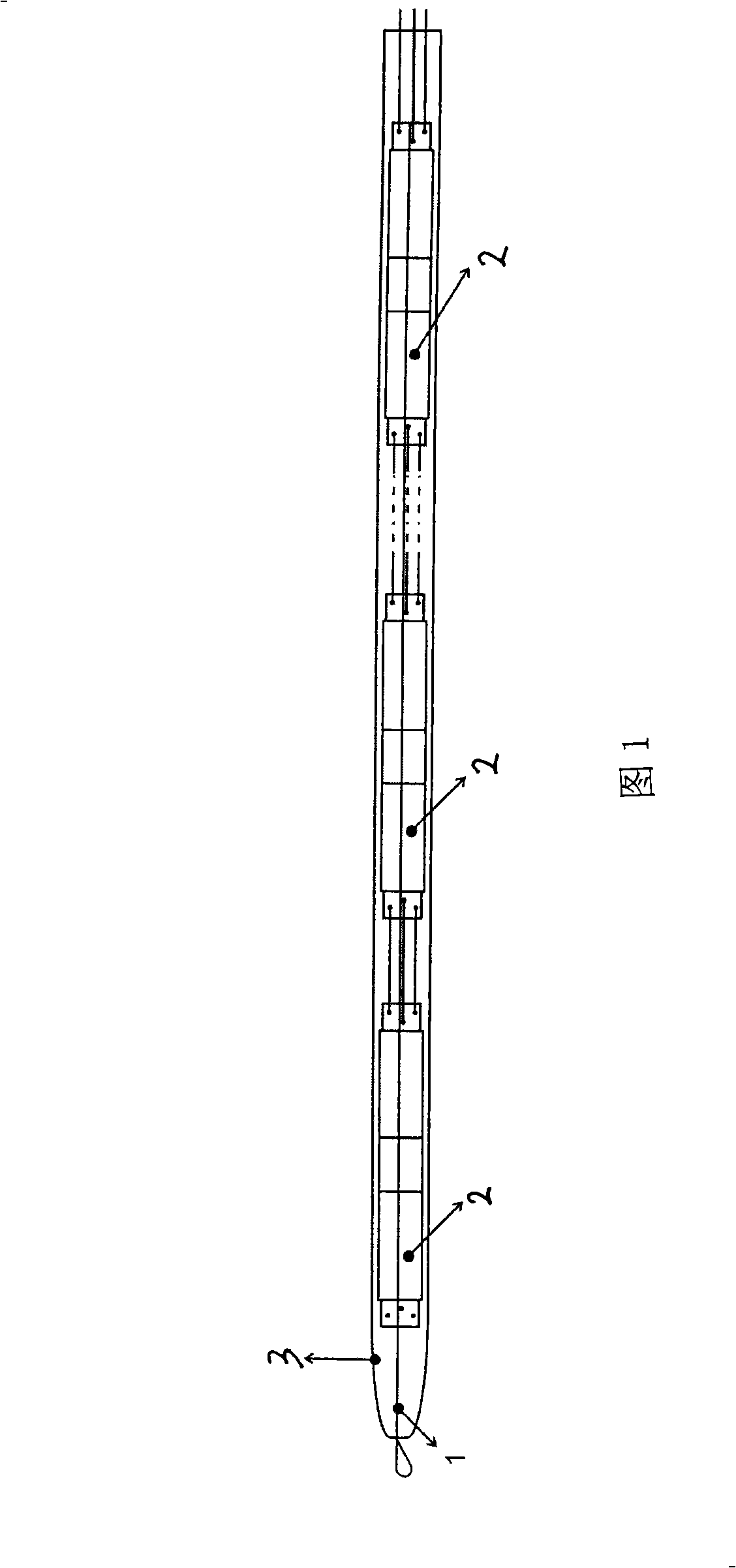

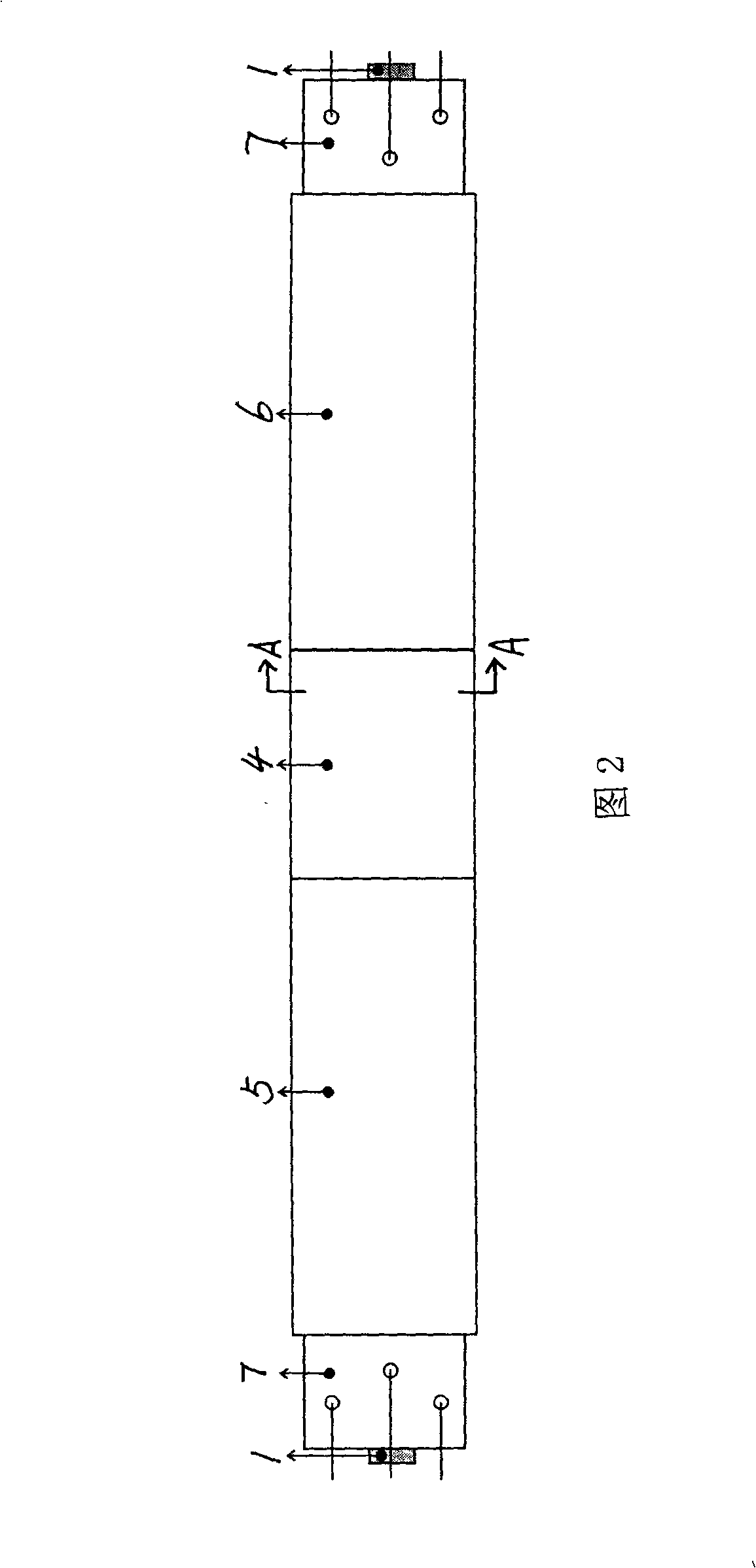

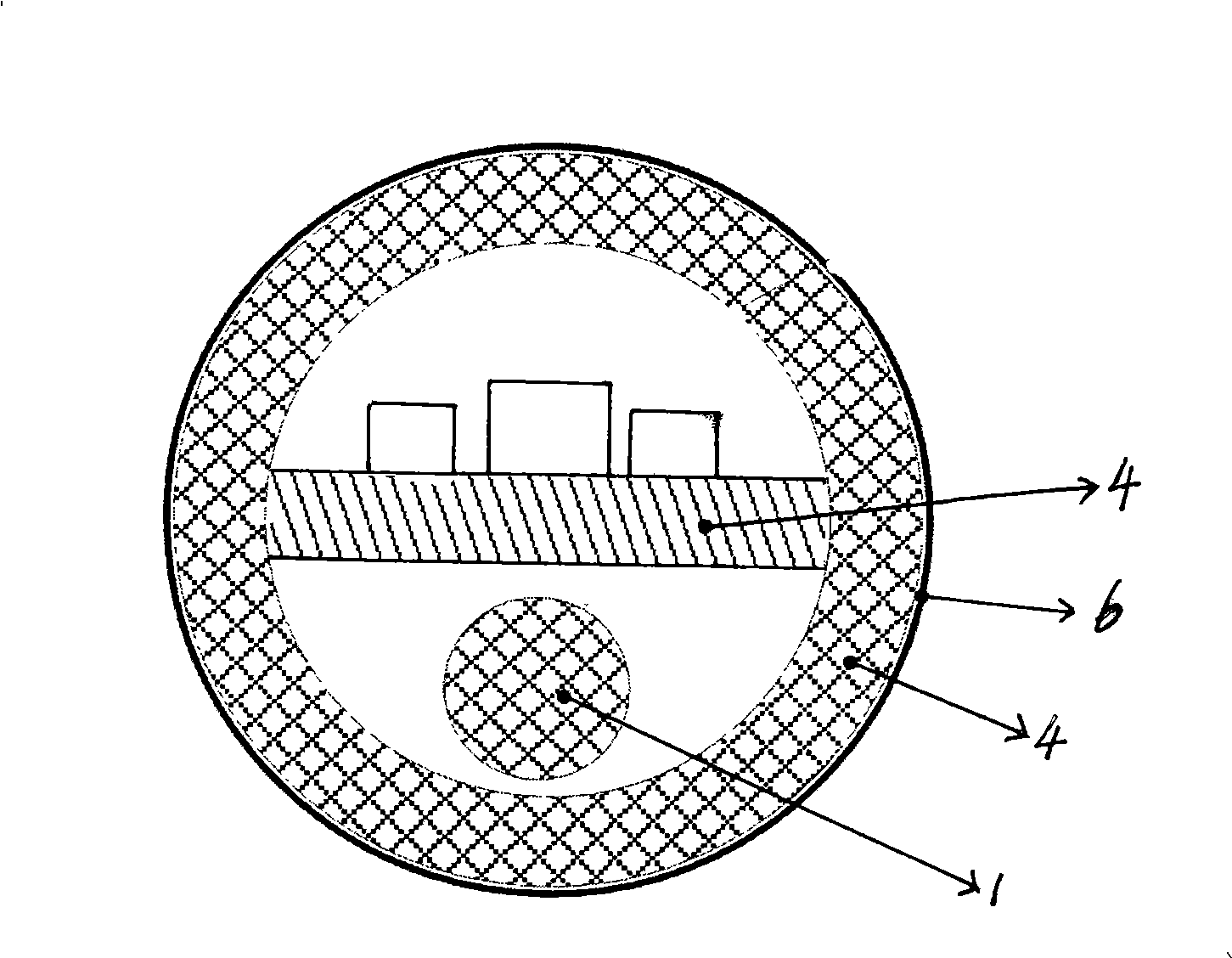

[0015] A digital sensor device for online measurement of grain temperature and moisture in grain depots, including a tensile steel wire rope 1, several parallel-connected grain temperature and moisture sensors 2 fixed along the tensile steel wire rope 1, outsourced to the tensile steel wire rope 1 and grain temperature and moisture The plastic cladding 3 outside the sensor 2 is connected with the digital signal transmission lines of each grain temperature and moisture sensor 2. Described grain temperature, moisture sensor 2 comprise the hard plastic tube 4 that is built-in thermistor, the metal cylinder 5,6 that forms detection capacitance that is respectively sleeved in hard plastic tube 4 two ends, is provided with in the hard plastic tube 4 and is used for measuring. A measuring circuit 7 for detecting the variation of capacitance and thermistor.

[0016] During specific implementation, the measurement circuit 7 includes a capacitance measurement chip IC2 and a microcontrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com