Laser transfer printing device and transfer printing head

A technology of laser transfer printing and transfer head, which is applied in the field of transfer printing head, and can solve problems such as being easily affected by electricity and magnetism, difficult servo control technology, and inability to adopt floating control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0128] Next, a preferred embodiment of the transfer head of the laser transfer device according to the present invention will be described in detail with reference to the drawings.

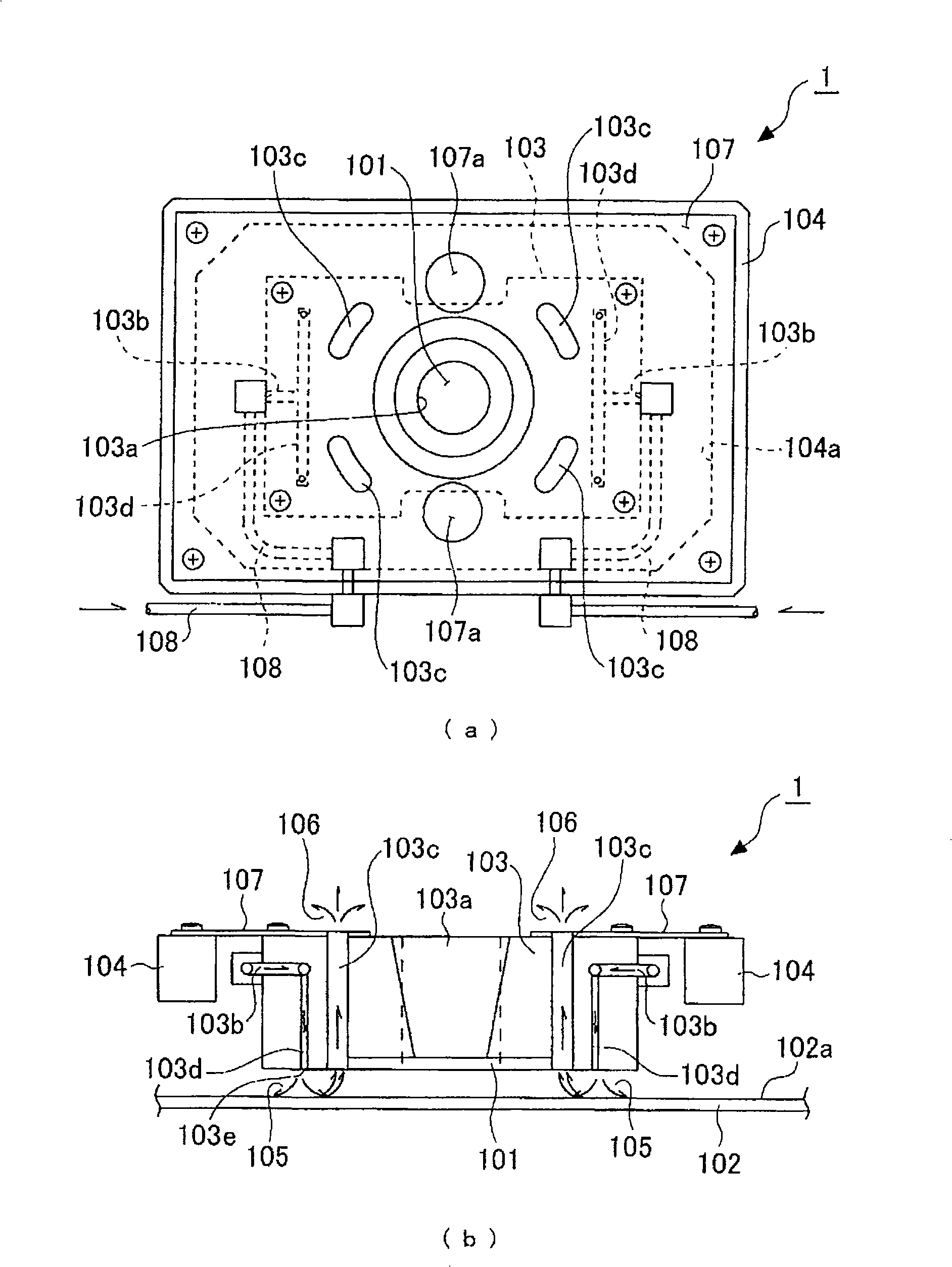

[0129] figure 1 (a), (b) are structural views showing the first embodiment of the transfer head of the laser transfer apparatus of the present invention. in addition, figure 1 (a) is a plan view, figure 1 (b) is a sectional view.

[0130] As can be seen from these figures, the transfer head 1 of the laser transfer apparatus places the transfer plate 101 so that the transfer material film (not shown) is opposed to the substantially horizontal transferred surface 102a of the transfer object 102. The transfer plate 101 is supported on the surface of a laser-transmissive plate-shaped small piece (for example, a plate-shaped small piece of quartz glass) with a fine and substantially constant gap between the two (in the figure). The bottom) is formed by covering a film of a transfer material (suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com