Manufacturing method of power-operated loudspeaker and diaphragm thereof

A technology for electric speakers and manufacturing methods, applied in the direction of transducer diaphragms, electromechanical sensors, sensors, etc., can solve the problem of affecting the impedance and distortion of electric speakers, the inability to simply determine technical measures and parameters, and the poor conductivity of aluminum strips Human satisfaction and other issues, to achieve the effect of overcoming inertial thinking and technical obstacles, excellent sound quality, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

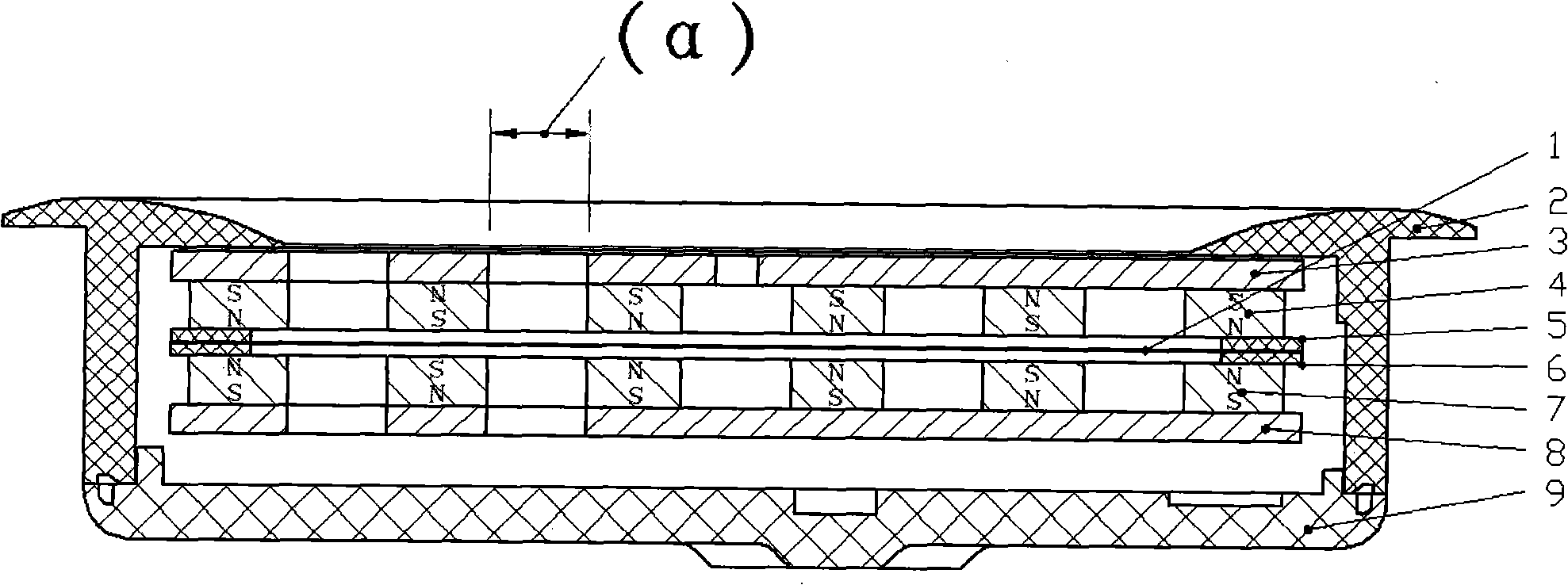

[0024] see figure 1 , an electric loudspeaker of the present invention includes an outer support (2, 9), a magnetic circuit device and a diaphragm 1.

[0025] The outer support (2, 9) is roughly columnar as a whole, the upper end is open, and the bottom end is then sealed. Specifically, it includes a chassis 9 for supporting, a column for edge sealing, and a hat brim 2 for fastening. The pillars can be integrally formed into a T-shape, and the pillars and the chassis 9 can be assembled by various known assembly methods such as screw locking, snapping, and bonding. This assembled combined structure is convenient for molding and process. Assembled, in this way, the outer support (2, 9) just forms a columnar accommodating space in its middle, and this accommodating space is used for accommodating the magnetic circuit device and the vibrating membrane 1. It sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com