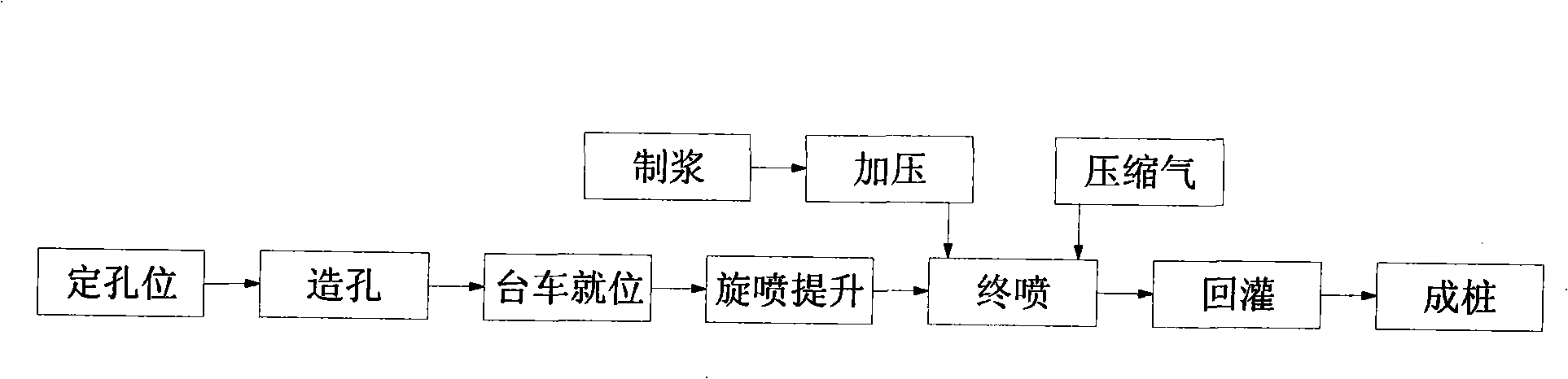

Construction process of water foundation ditch rotary churning pile water stopping curtain

A construction technology and water-stop curtain technology, which is applied in foundation structure engineering, sheet pile wall, excavation, etc., can solve problems such as difficulty in digging foundation pit to the design depth, loss of soil bearing capacity, and deterioration of construction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

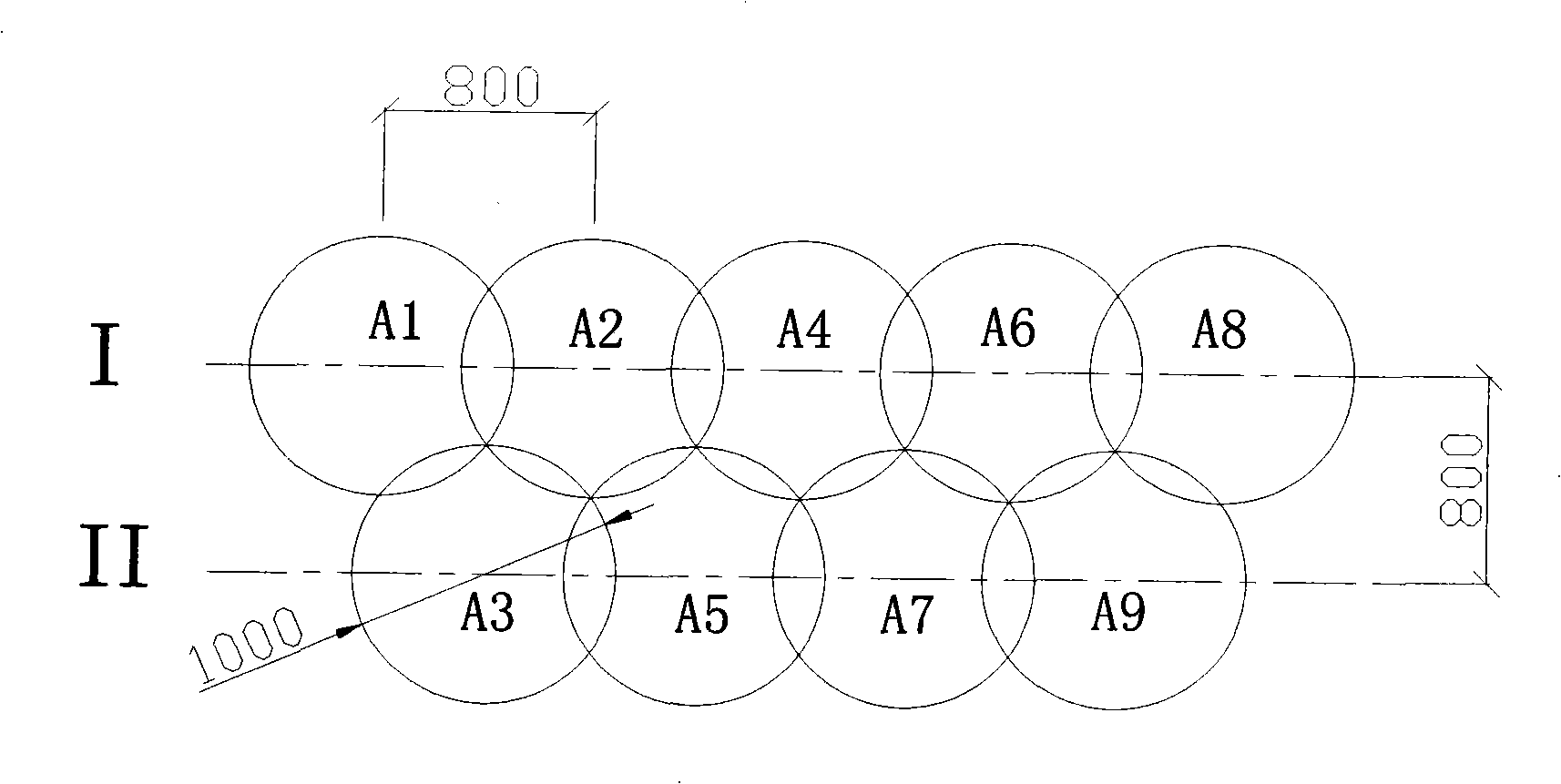

[0011] The present invention is two large-scale dock projects according to the No. 1 and 2# docks of the Changxing Shipbuilding Base of China Shipbuilding Base, and the scales of the docks are respectively 520m × 76m × 11.5m and 510m × 116m × 11.5m as specific examples to illustrate, 1# , 2# Dock entrance uses high-pressure jet spray piles as a water-stop curtain, which are connected with steel sheet piles on the dock wall to form a water-stop system for the dock. The water-stop curtain at the dock mouth is arranged along the front of the dock mouth, on both sides and three sides, and adopts double rows of high-pressure rotary grouting piles in a plum-shaped arrangement with a row spacing of 800mm. The designed pile diameter is φ1000mm, the spacing is 800mm, and the overlap between piles is 200mm. The jet grouting pile is 15.55m long, with a bottom elevation of -26.0m and a top elevation of -10.45m. A total of 869, with a total volume of about 10613m3, including 397 at the 1# ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com