All-tooth profile engaged dedicated gear

A tooth profile and meshing technology, applied in the direction of rotary piston/oscillating piston pump components, machines/engines, pump components, etc., can solve problems such as thermal cracking and curing phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

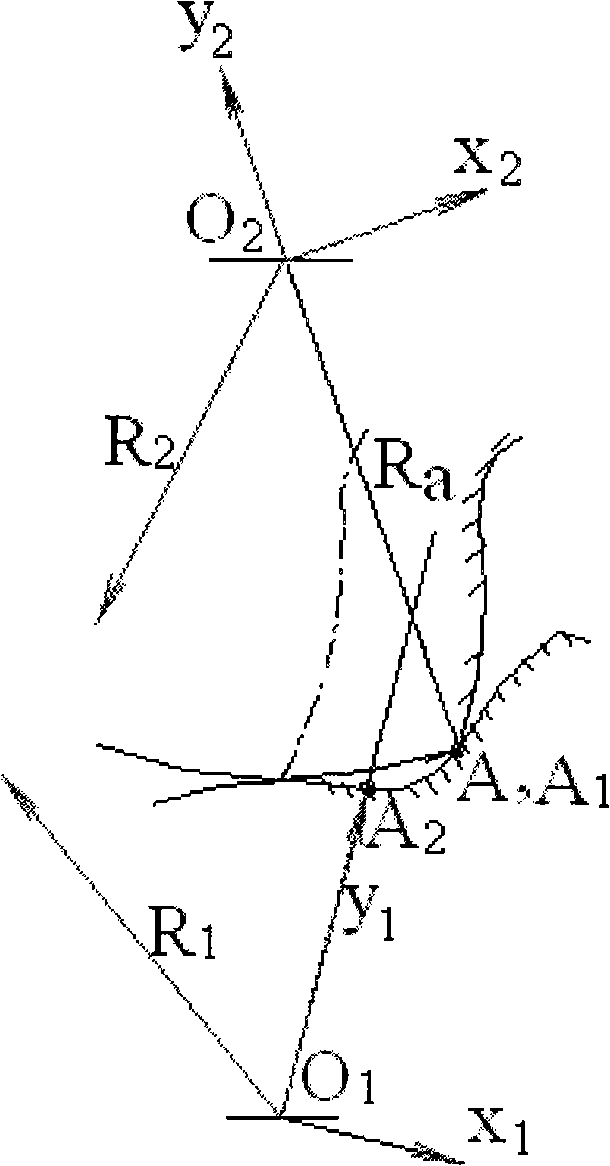

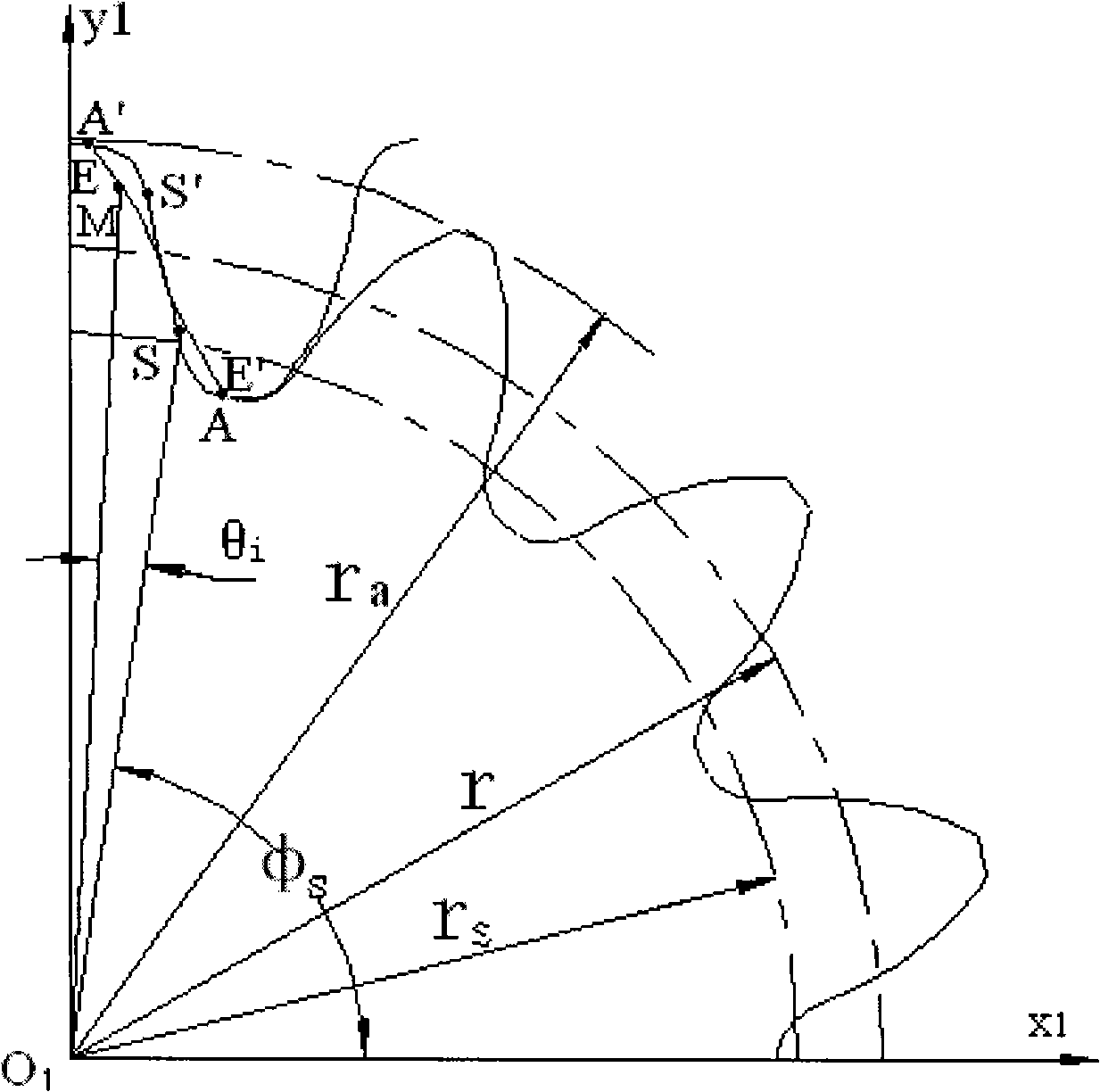

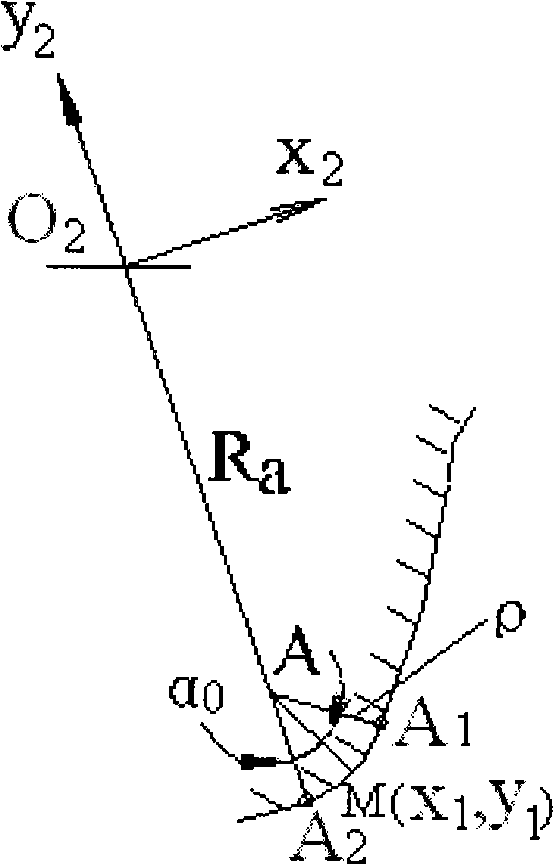

Method used

Image

Examples

Embodiment 1

[0033] The basic parameters of the gear are: the modulus of the gear end face m t =10.8857, the number of teeth of 2 meshing gears z 1 =z 2 =14, end face pressure angle α t =30°, tooth width b=127mm, helix angle β=15°, gear center distance a=152.4mm.

Embodiment 2

[0035] Gear basic parameters: gear end face modulus m t =2.6, the number of teeth of 2 meshing gears z 1 =z 2 =42, end face pressure angle α t =30°, tooth width b=45mm, helix angle β=10°, gear center distance a=109.2mm.

Embodiment 3

[0037] Basic parameters of gear: end face pressure angle α t =30°, 2 meshing gear teeth number Z 1 = Z 2 =14, gear end face modulus m t =12.856, helix angle β=21°2'22", gear center distance a=180mm, tooth width b=110mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com