Large wind barn small air scoop crossbeam type chain-grate

A technology of chain grate and air bucket, which is applied in the direction of mobile grate, grate, lighting and heating equipment, etc. It can solve the problems of reducing combustion efficiency, uneven air distribution, and affecting combustion, so as to improve combustion quality and supply power. The effect of uniform wind and stable wind pressure

Inactive Publication Date: 2008-10-22

瓦房店市永宁机械厂

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the combustion equipment used in large boilers is mainly beam type chain grate. The structure of beam type chain grate is a frame composed of middle beam, upper guide rail and lower guide rail. Connected with the driving device, each independent air chamber is formed under the upper furnace chain and between the adjacent middle beams, and the air is supplied in sections through each independent air chamber and the air supply device connected to the air chamber. This structure Due to the high wind speed entering the grate, the large proportion of dynamic pressure, and the existence of serious wind diffusion and eddy currents, the air distribution on the grate surface is uneven, and the wider the grate is, the more obvious this phenomenon is. Affect combustion, reduce combustion efficiency and waste coal resources

The existing beam-type chain grate adopts ordinary plate-type wall panels with air inlets connected to the air supply device. The area of the air inlets is smaller than the cross-sectional area of each air chamber. The change of static pressure distribution caused by the diffusion of airflow can also lead to uneven air distribution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

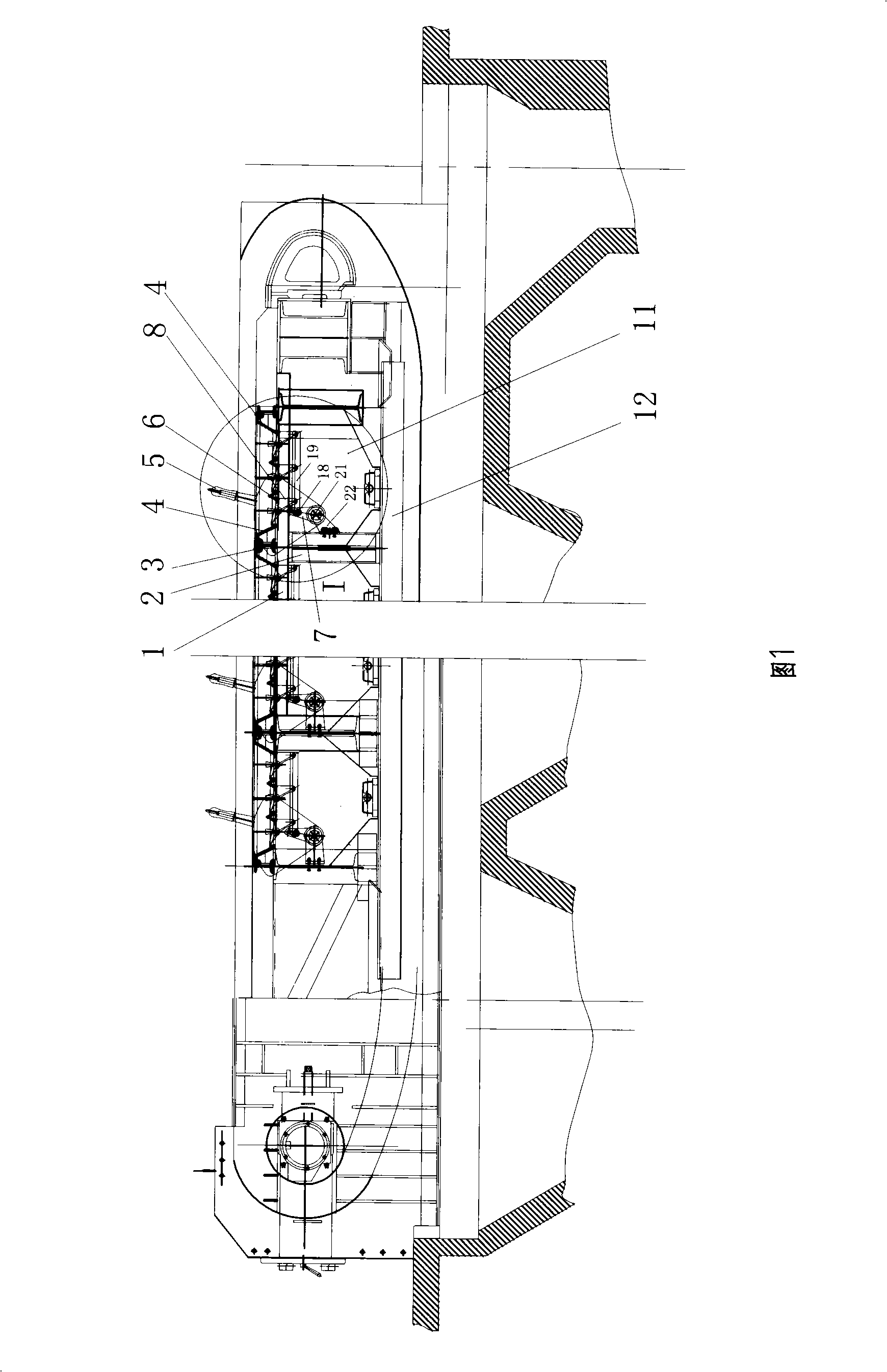

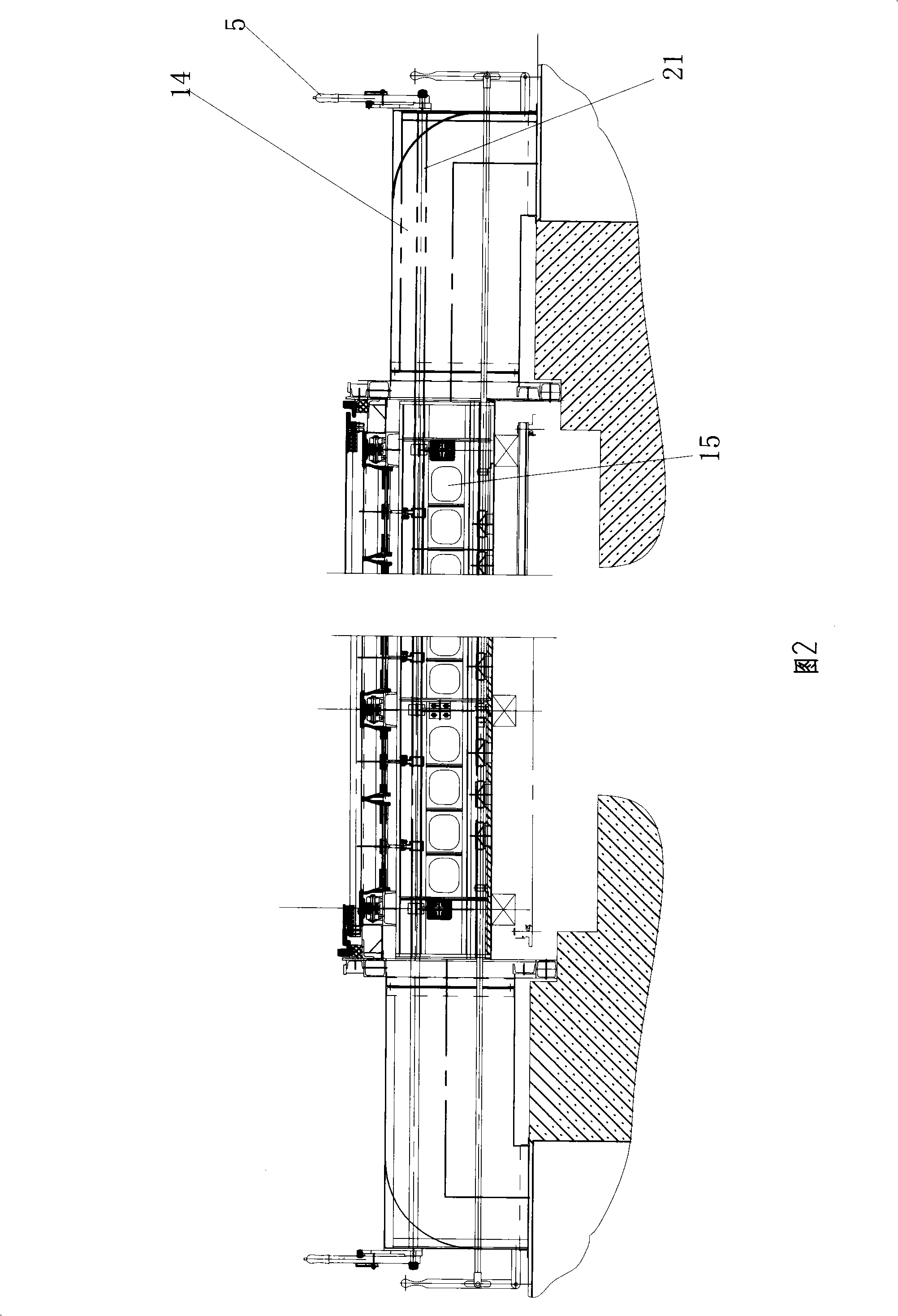

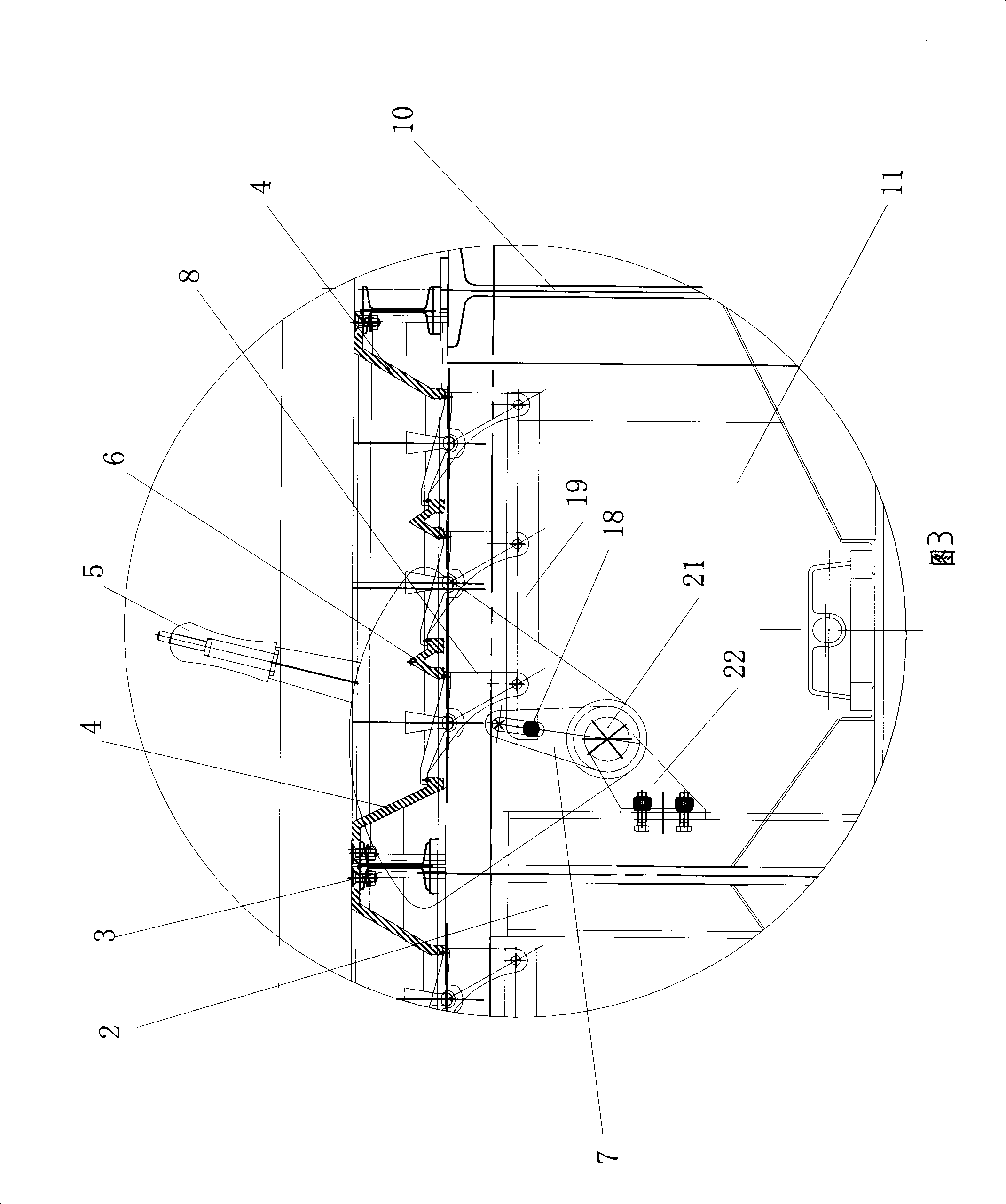

The invention discloses an endless grate, in particular to a big wind bin and small wind catcher crossbeam-type endless grate. The endless grate comprises a frame consisting of a middle beam (2), an upper lead rail (1) and a lower lead rail (12); a furnace chain connected with a drive device is arranged on the frame; the endless grate is characterized in that: the lower part of the furnace chain on the upper part is provided with a wind bin (11) communicated with the furnace chain; a wind chest (14) communicated with the wind bins (14) is arranged on the whole side of the grate; the wind chest (14) is connected with a wind supply device. The endless grate changes the mode that each wind chamber respectively supplies wind in the prior art, thereby greatly reducing wind speed, stabilizing wind pressure, ensuring the even wind supply to the furnace chain, improving the burning quality of fuel and saving energy.

Description

Large wind warehouse and small wind bucket beam type chain grate Technical field The invention relates to a chain grate, in particular to a cross-beam type chain grate with a large wind chamber and a small wind bucket. Background technique At present, the combustion equipment used in large boilers is mainly a beam type chain grate. The structure of the beam type chain grate is a frame composed of a middle beam, an upper guide rail and a lower guide rail. The furnace chain and the furnace chain are supported on the frame. Connected with the driving device, each independent air chamber is formed between the adjacent middle beams under the upper furnace chain, and the air is supplied in sections through each independent air chamber and the air supply device connected to the air chamber. This structure Due to the high wind speed entering the grate, the dynamic pressure ratio is too large, and there are serious wind diffusion and eddy currents, resulting in uneven air distribution on...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23H11/02F23H11/10

Inventor 刘玉振

Owner 瓦房店市永宁机械厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com