All-bomb automatic assembly line

An assembly line, automatic technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of many dangerous objects, dangerous accidents, safety accident personnel and property losses on the production site, and achieve good service performance, high degree of automation, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

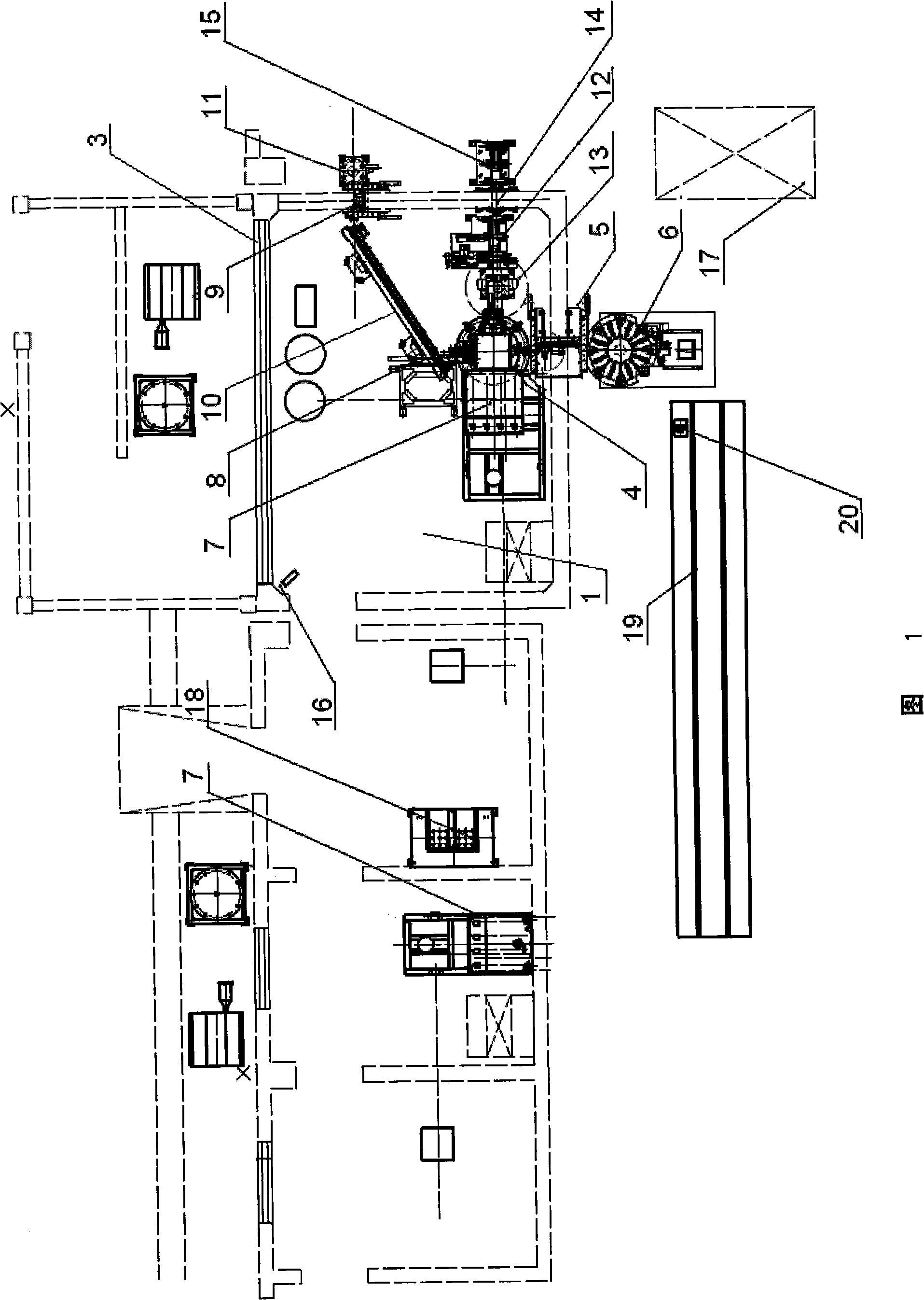

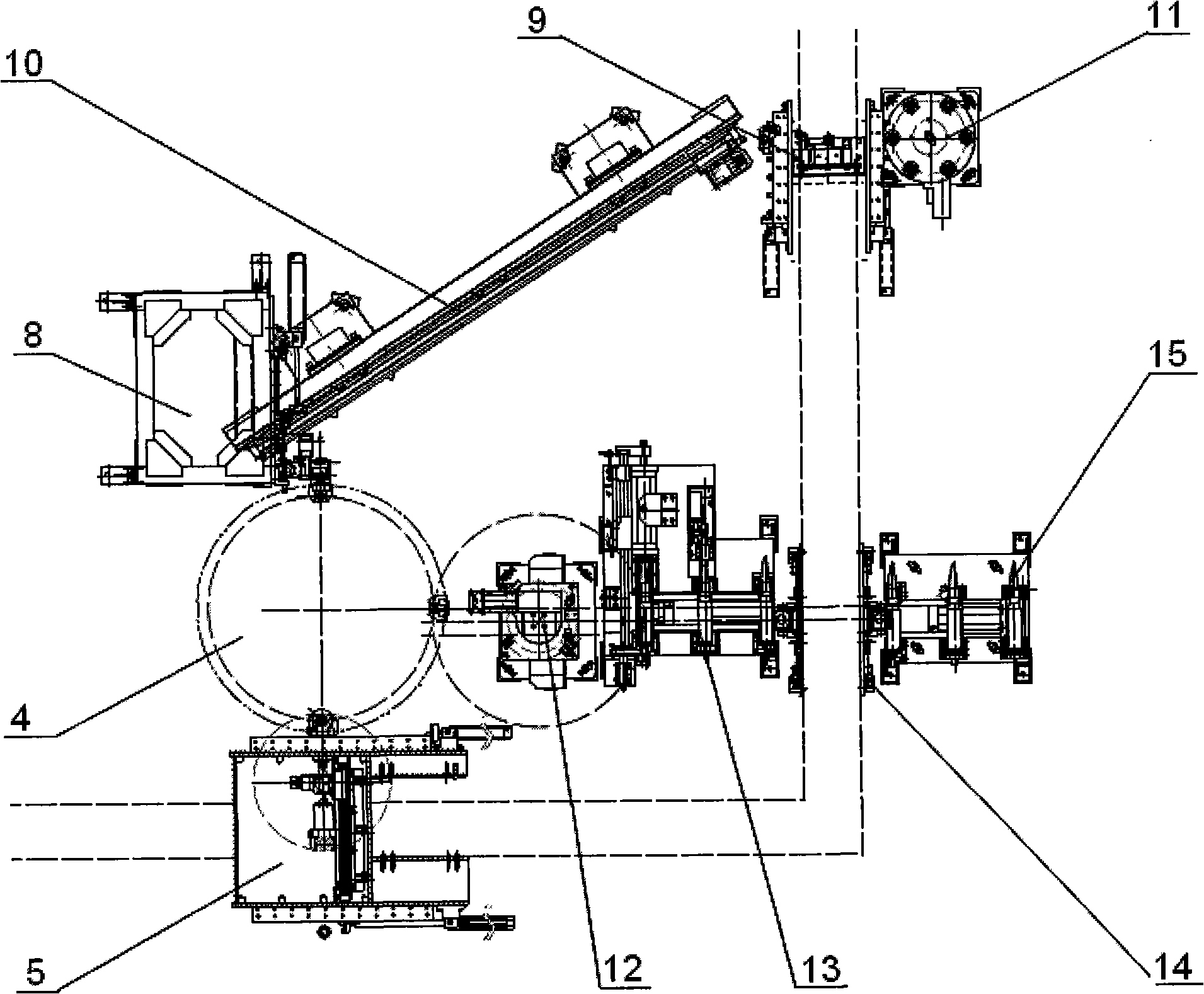

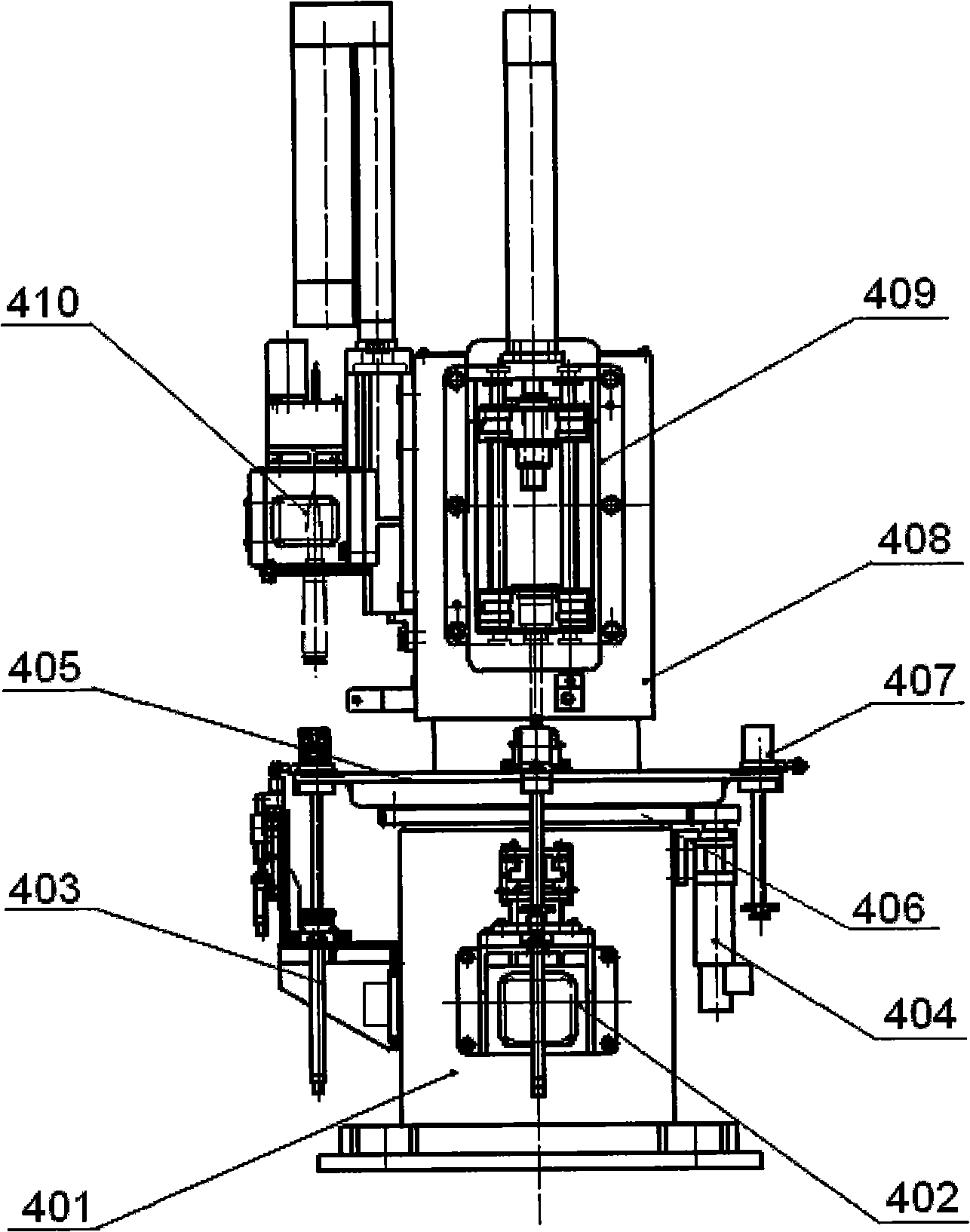

[0029] Figure 1, figure 2 As shown, the present invention includes an anti-explosion room 1, and the anti-explosion room 1 is surrounded by three concrete walls 2 and one anti-explosion wall 3. An assembly host 4 is arranged in the concrete wall 2 close to the front side, a cartridge transfer window 5 is arranged on the concrete wall 2 of the front side, and a primer tightening device 6 is arranged outside the cartridge transfer window 5 . A medicine weighing machine 7 is arranged on the left side of the assembly host 4, an upper projectile manipulator 8 is arranged on the rear side of the assembly host 4, and an incoming projectile transfer window 9 is arranged on the concrete wall 2 on the right side, and the upper projectile manipulator 8 and the incoming projectile transfer window 9 are arranged. A projectile conveyor 10 is arranged between the windows 9, and a projectile turntable 11 is arranged outside the projectile transfer window 9. On the right side of the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com