Iron core construction with unequal intersecting surface for working at saturated magnetization zone

An iron core, unequal technology, applied in the field of cross-section iron core structure and electromagnetic equipment, can solve the problems of reducing the voltage drop of the current limiter, the influence of the normal operation of the power grid, and reducing the flexibility, and achieve the effect of reducing the influence and eliminating the adverse influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

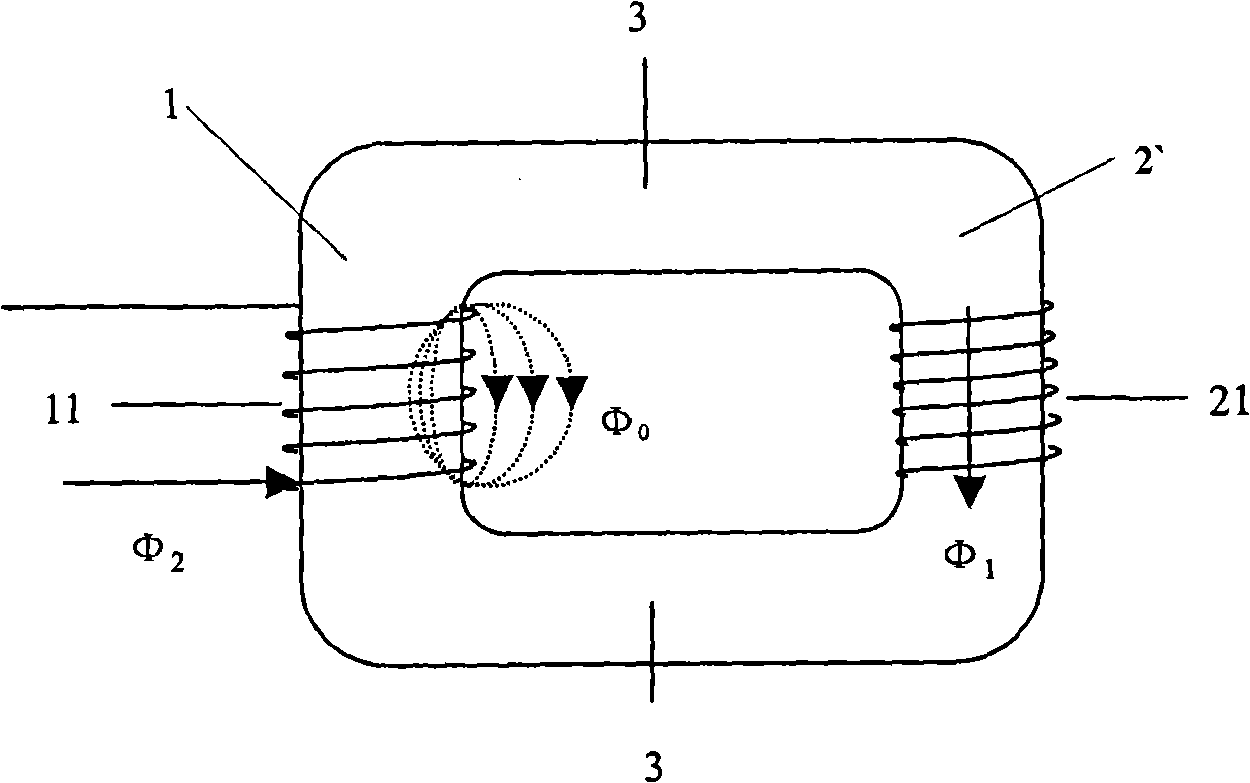

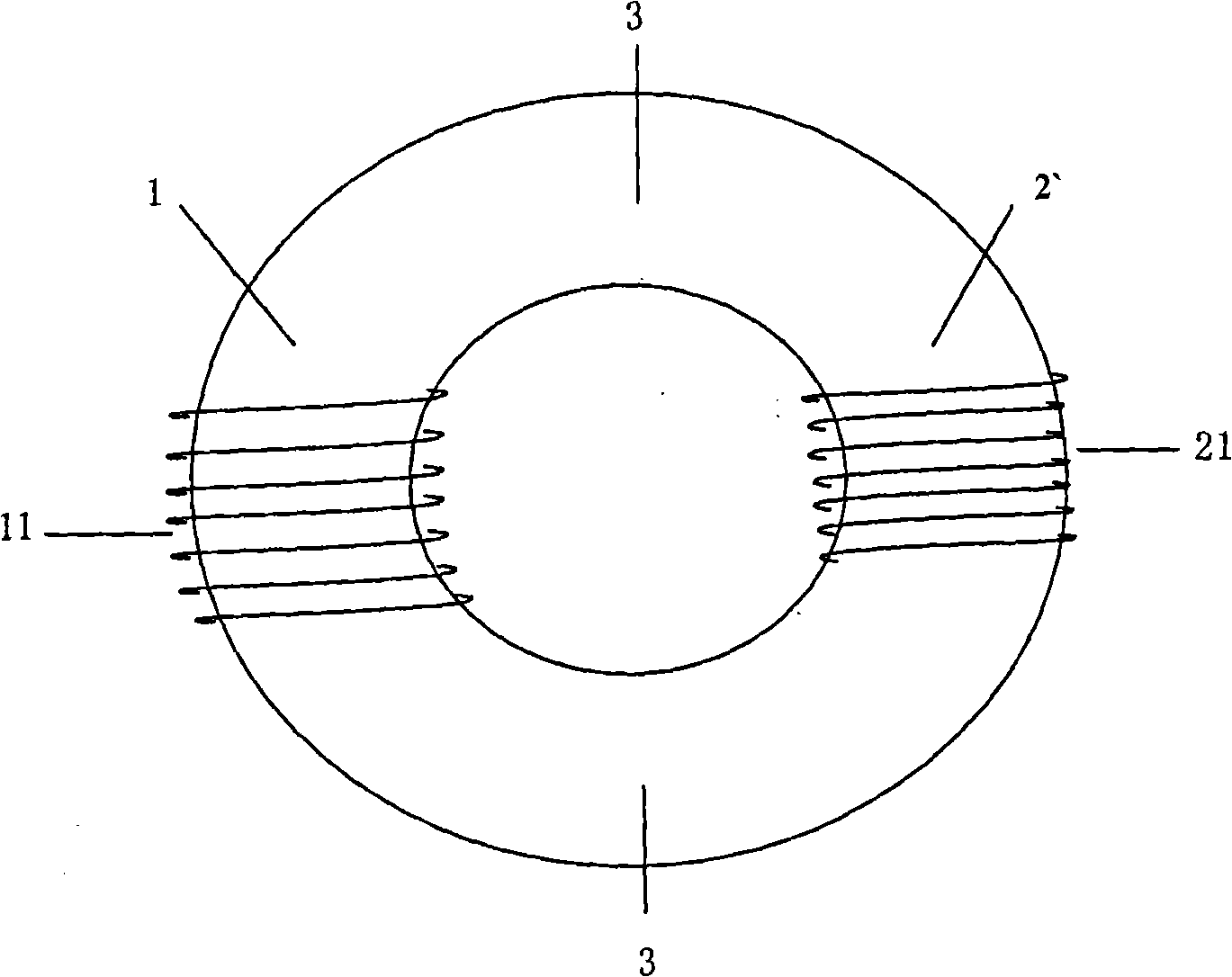

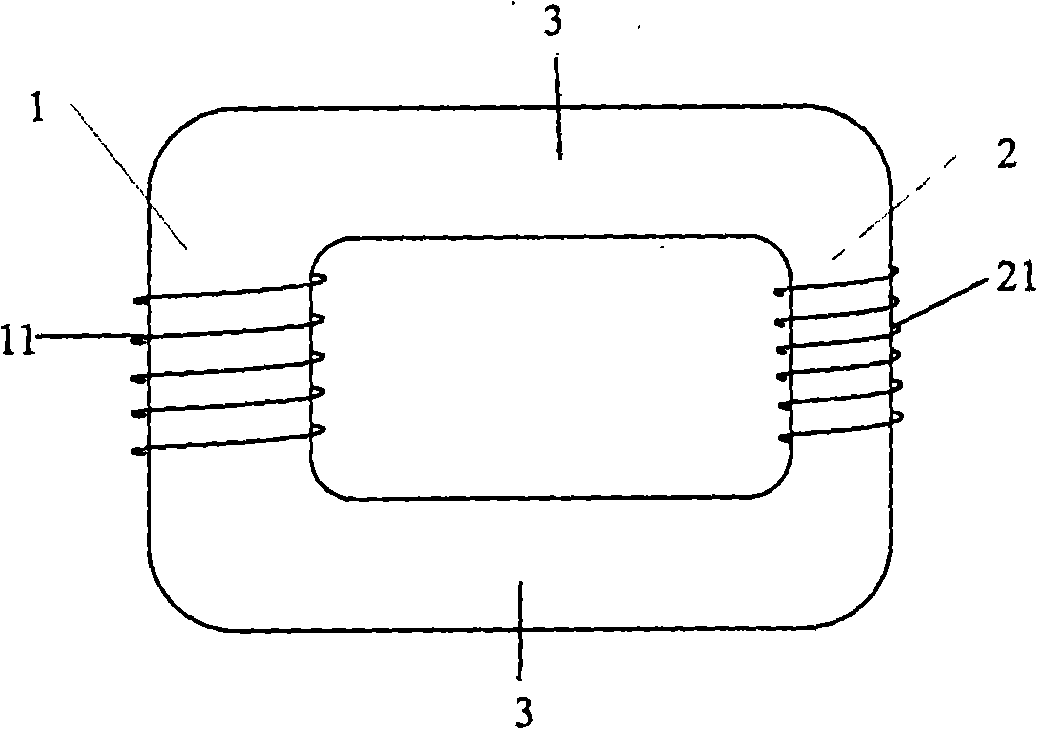

[0033] Fig. 2-1(a) is a schematic diagram of an embodiment of the present invention with a square-shaped iron core structure with unequal cross-section for working in the magnetic saturation region and the working winding 21 is wound on a position opposite to the magnetic conducting winding 11, which provides a The unequal cross-section core structure is used to work in the magnetic saturation area. The core is a closed core, including the excitation section 1, the working section 2 and the magnetic conduction section 3. Among them, the cross-sectional area of the iron core of the excitation section 1: the core of the working section 2 Cross-sectional area = 1.01 ~ 10, the preferred value range of this ratio is 1.2 ~ 3, the cross-sectional area of the iron core of the excitation section 1: the cross-sectional area of the magnetic sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com