Wafer quality analysis method and device

A quality analysis and wafer technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of unstable wafer quality analysis results, subjective wafer quality analysis, etc., and achieve significant failure distribution types and short quality analysis time. , the process of determining the fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

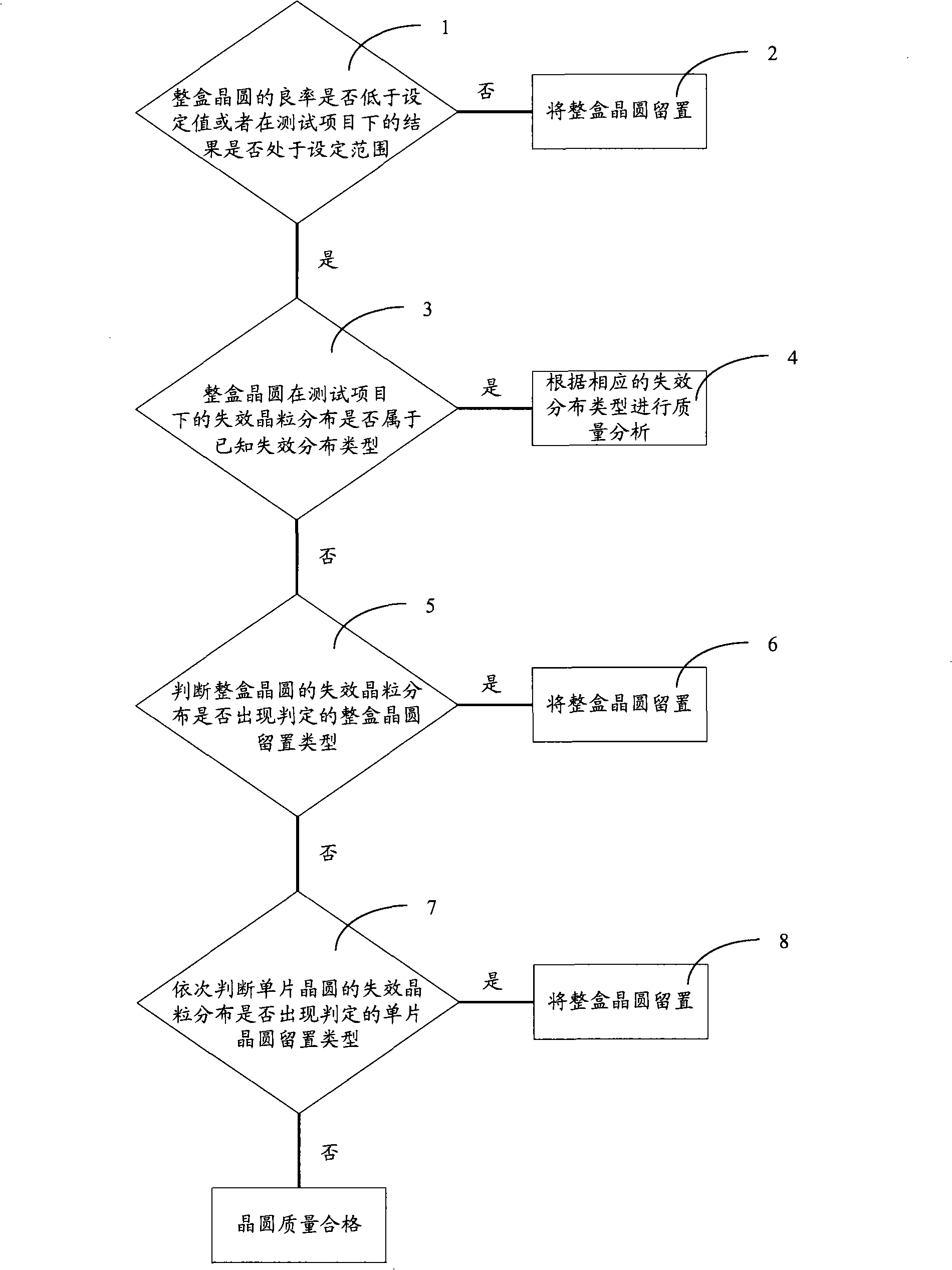

[0036] The wafer quality analysis method of the present invention is to determine the failure of the wafer by comparing the failure grain distribution of the analyzed wafer with the known failure distribution type and the determined full box wafer retention type and single wafer retention type distribution type, and perform quality analysis according to the failure distribution type.

[0037] refer to figure 1 As shown, the wafer quality analysis method of the present invention comprises the following steps,

[0038] Step 1, determine whether the yield rate of the whole box of wafers is lower than the set value and whether the results under the test items are within the set range. As mentioned above, after a series of wafer yield tests, including the yield test of the whole box of wafers and the yield test of a single wafer, the yield and failure grain distribution results of the whole box of wafers will be obtained As well as yield and failed grain distribution results for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com