Oscillating axle for a lifting device, lifting device comprising such an axle and control method

a technology of oscillating axle and lifting device, which is applied in the direction of lifting device, lifting frame, safety device for lifting equipment, etc., can solve the problems of machine risking overturning and wheel losing contact with the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

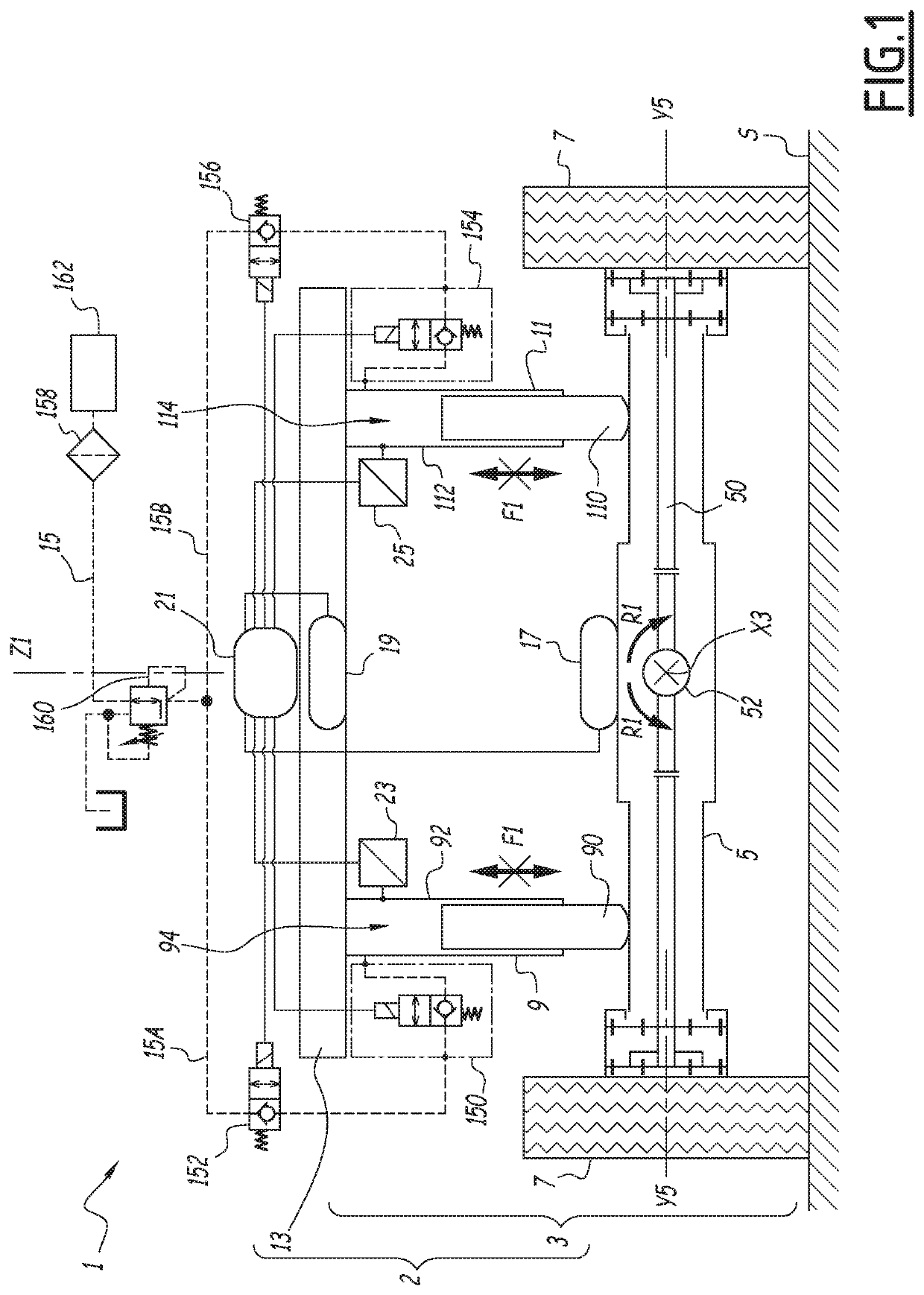

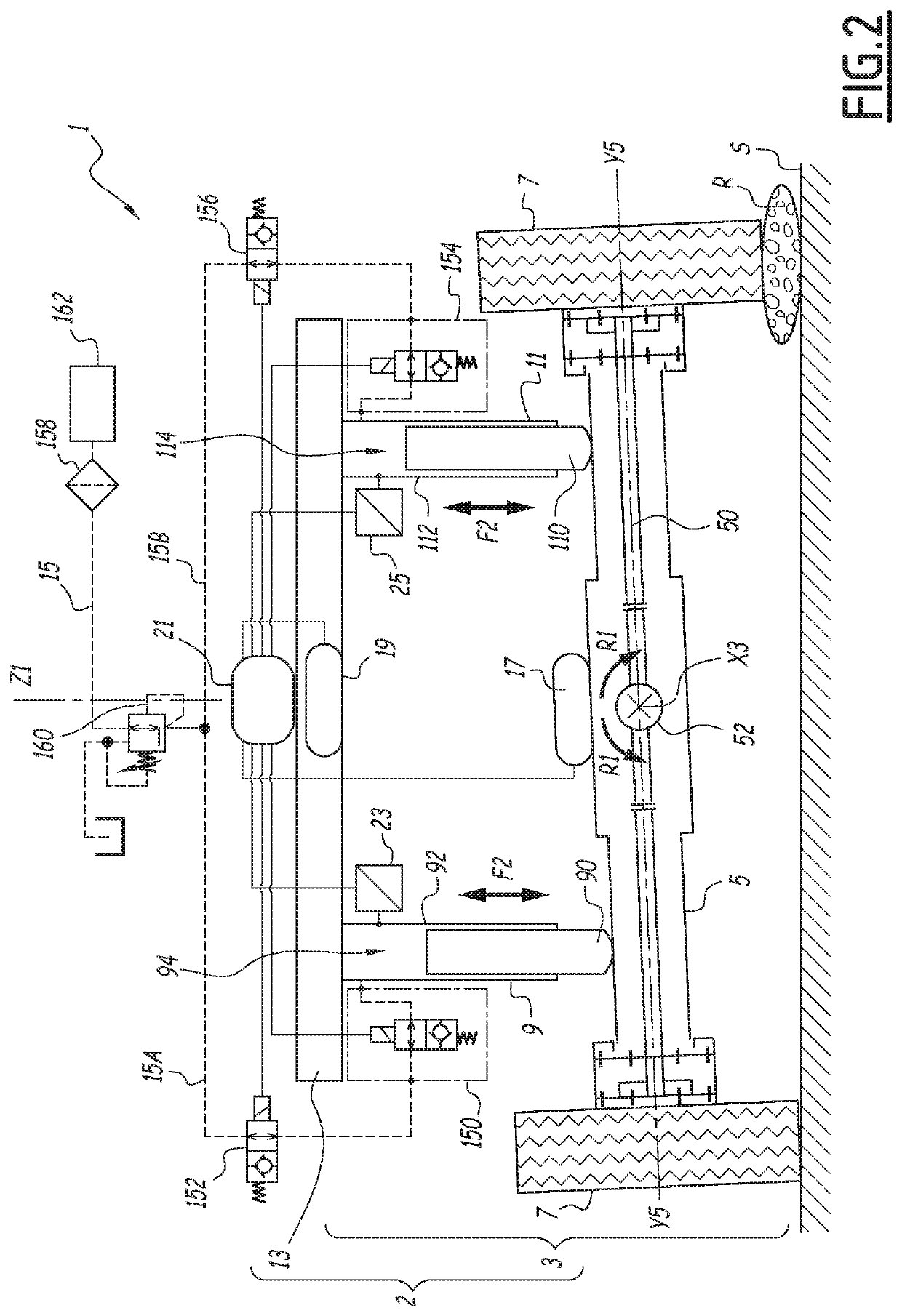

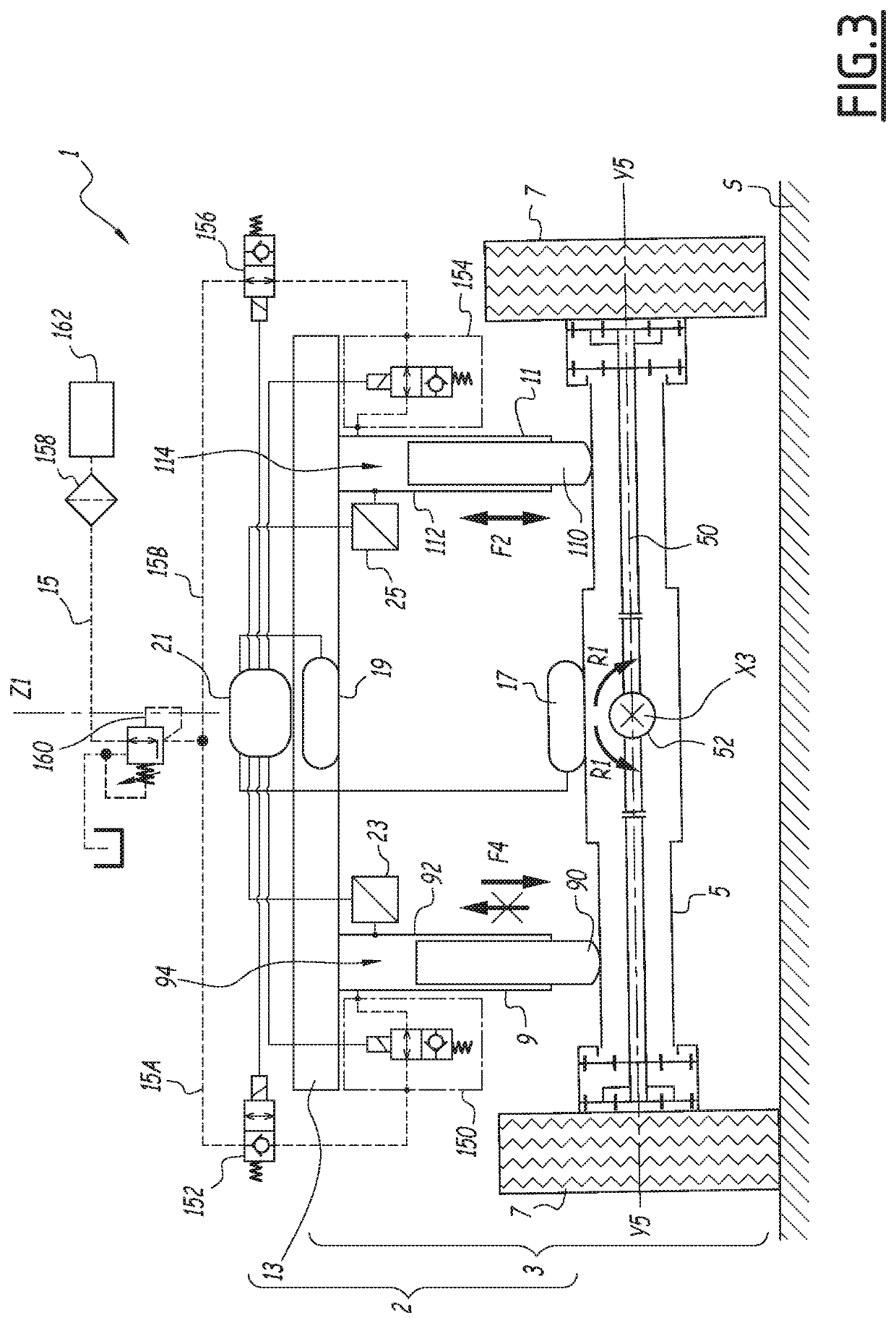

[0034]FIGS. 1 to 3 show a lifting device 1, such as a lifting platform, comprising a lower part comprising a chassis 2 and members connecting with the ground, and a lifting structure (not shown) supporting a platform (not shown). The lifting structure may be of the type comprising telescopic and articulated sections, or else of the “scissor” type.

[0035]In a conventional example, the lower part comprises four members connecting with the ground in the form of the wheels 7. The chassis 2 comprises a fixed part 13 and at least one oscillating axle, one of the latter of which is shown in FIG. 1 with the reference 3. The wheels 7 are mounted two by two on the axles. The fixed part 13 is fixed relative to a vertical axis Z1 of the lifting device 1.

[0036]The oscillating axle 3 comprises a bridge 5 having, at each of its ends, a wheel 7. The bridge 5 is a mechanical structure supporting the wheels 7, which includes a transmission shaft 50 to rotate the wheels 7 and which is also capable of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com