Garbage truck carriage welding bench

A garbage truck and workbench technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to ensure the size requirements of large boxes, inaccurate positioning of large boxes, poor production consistency, etc., to achieve Improve assembly and welding efficiency, simple and compact structure, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

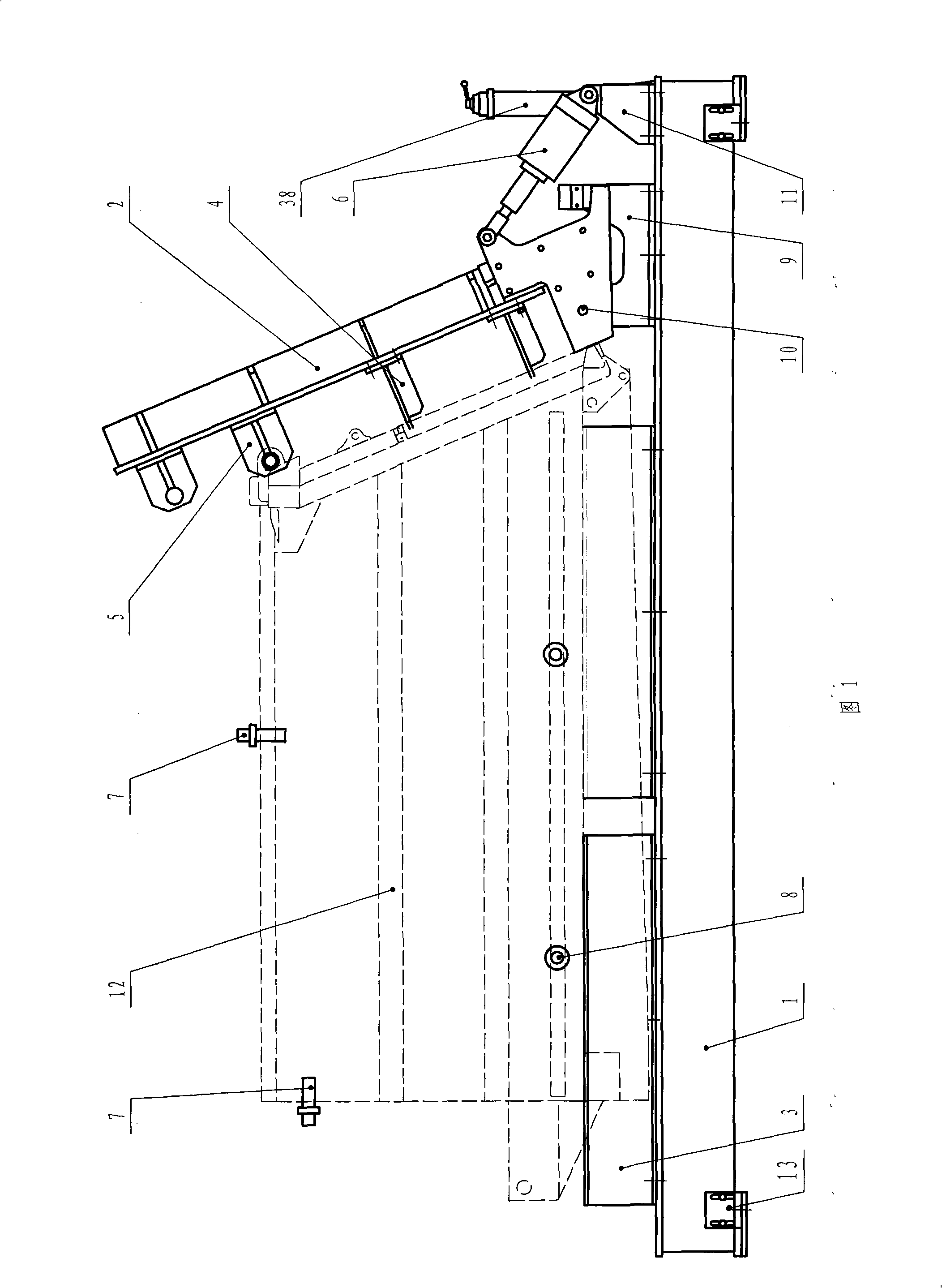

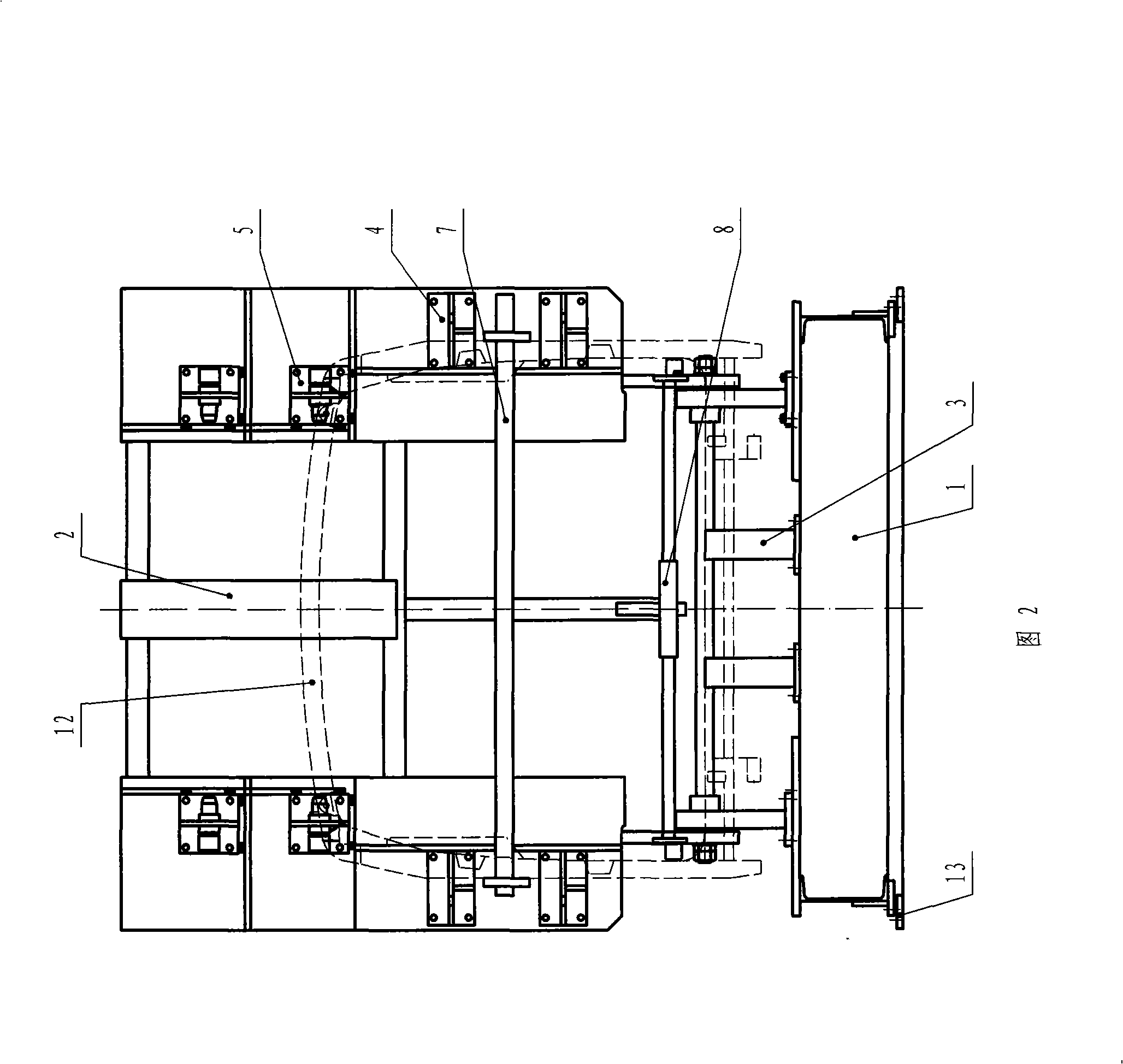

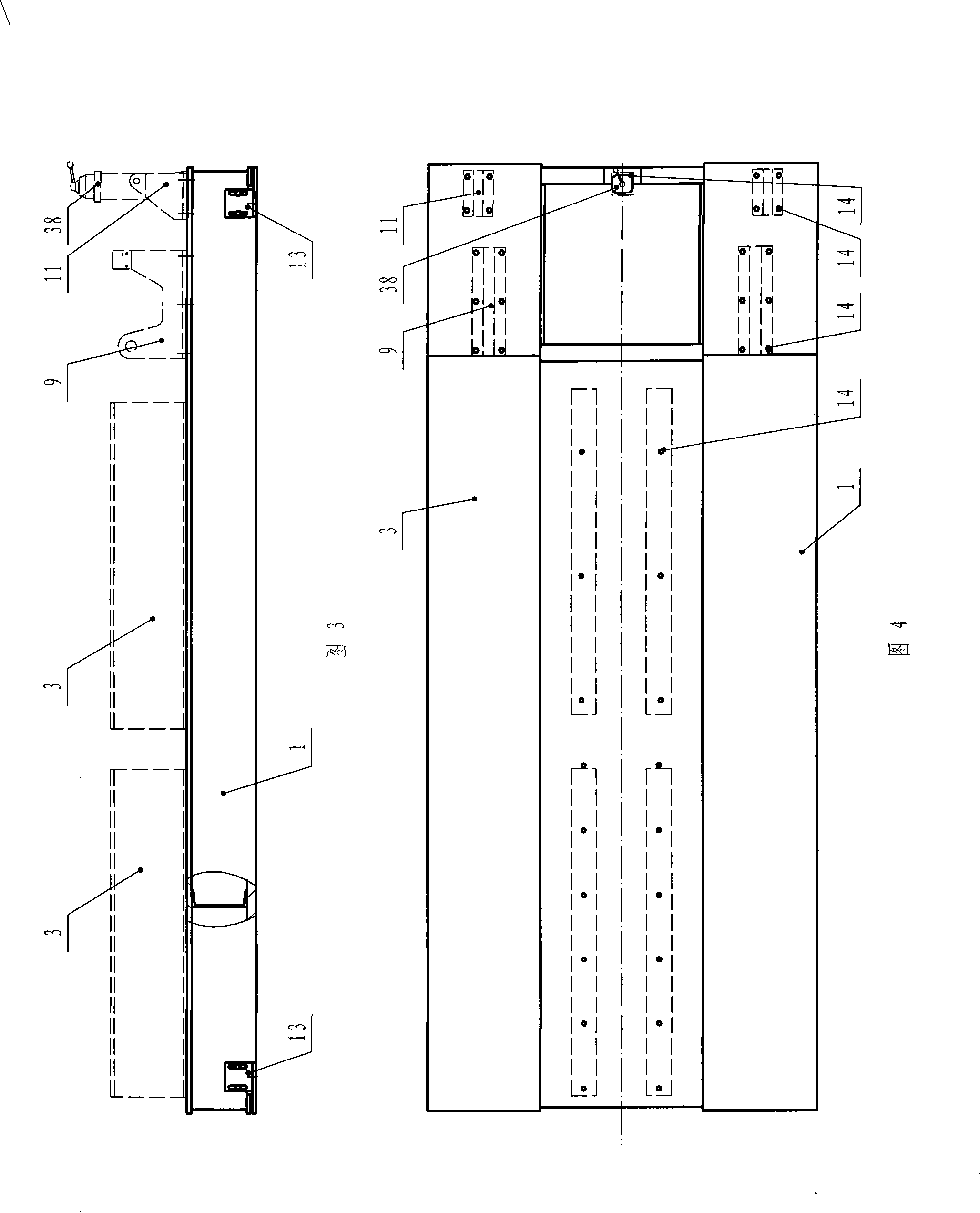

[0031] The garbage truck compartment welding workbench shown in Figure 1-16 includes a fixed stand 1, a swing stand 2, a bottom plate positioning seat 3, a side plate positioning seat 4, a top plate positioning seat 5, a swing cylinder 6, and a replaceable positioning block 9. The rotating shaft 10 and the hydraulic controller 38 have a structure as follows: the fixed mount platform 1 is fixed on the ground, and the front and rear sides of the leftmost end of the fixed mount platform 1 are provided with positioning brackets 11, located on the left side of each positioning bracket 11, and on the left side of each positioning bracket 11. The fixed frame 1 is provided with a replaceable positioning block 9, the swing frame 2 is hinged with the replaceable positioning block 9 through the rotating shaft 10, the fixed end of the swing cylinder 6 is hinged with the positioning bracket 11, and the telescopic end of the swing cylinder 6 is connected to the swing through the pin shaft. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com