Hyperacoustic frequency electromagnetic bowl energy-saving heating apparatus

An electromagnetic roller and heating device technology, applied in decorative arts, embossed decorative parts, etc., can solve the problems of difficulty in eliminating dripping, restricting the development of production, affecting the working environment, etc., achieving elimination of dripping, good quality, and quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

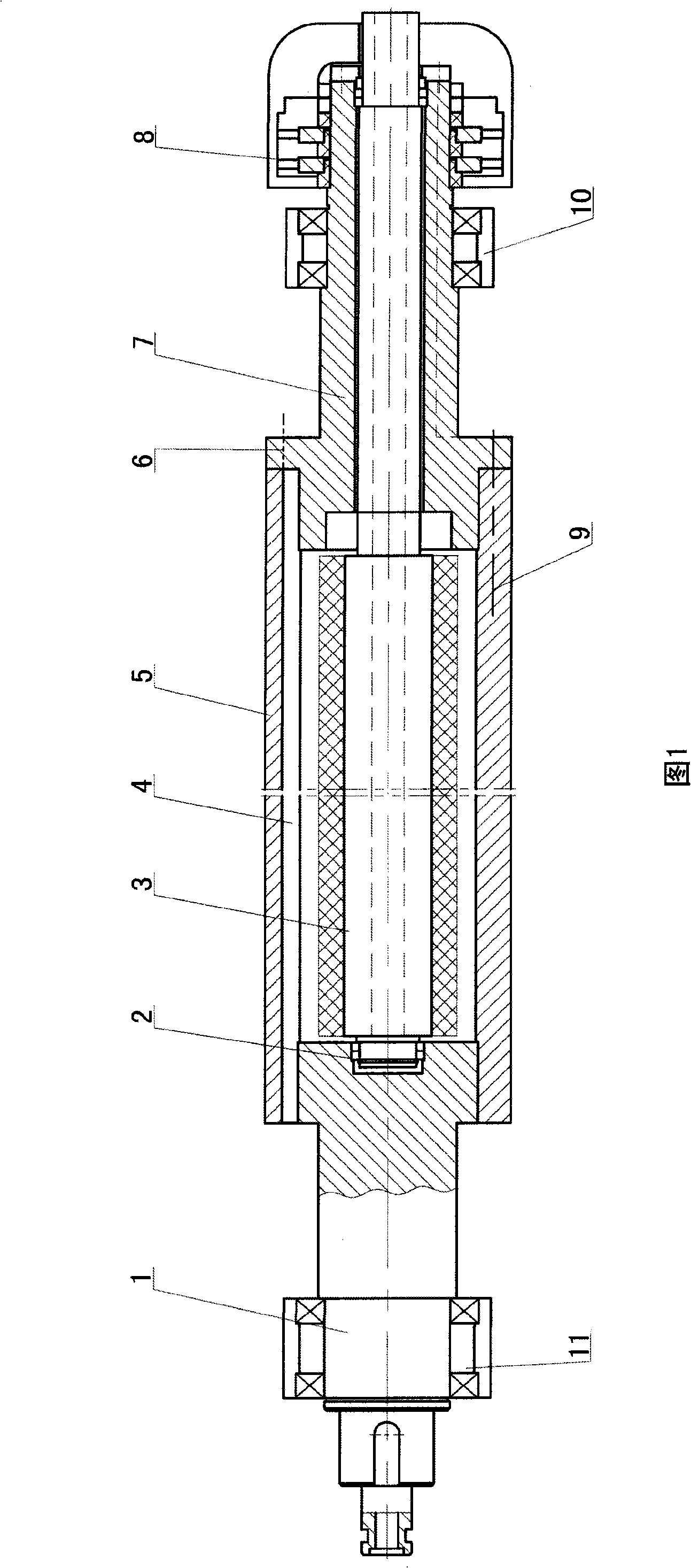

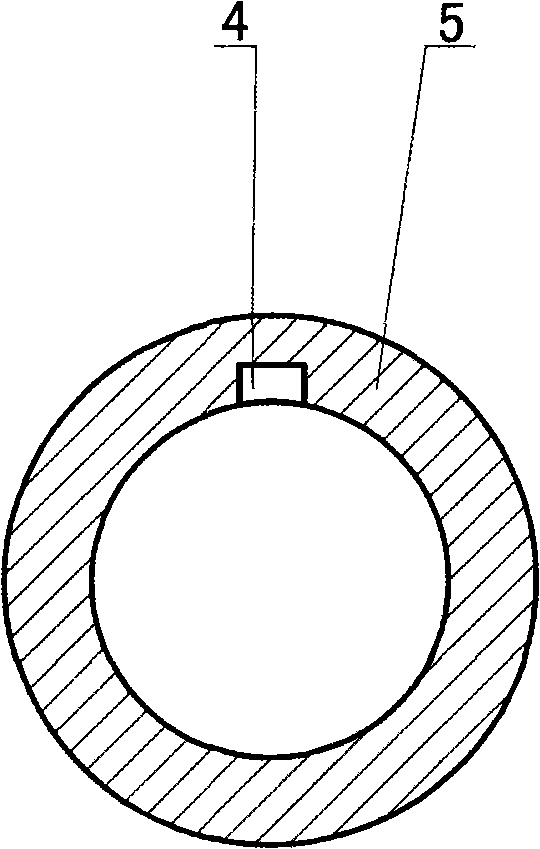

[0024] As shown in Figures 1 and 2, a supersonic frequency electromagnetic roller energy-saving heating device in this embodiment includes a left end shaft 1, a hollow roller 5, a right end shaft 7, an electromagnetic induction heater 3, and the inner wall of the roller 5 The magnetic isolation block 4 is inlaid on the top, and the right end shaft 7 has a through hole extending axially. The insertion ends of the left end shaft 1 and the right end shaft 7 are respectively inserted into the roller 5 from one end of the roller 5 to form the inner cavity of the roller. The magnetic induction heater 3 is arranged in the inner cavity of the roller, and one end of the electromagnetic induction heater 3 is rotatably fixed on the insertion end of the left end shaft 1, and the other end of the electromagnetic induction heater 3 passes through the through hole of the right end shaft 7 and protrudes from the right end. Axis 7 outside. The electromagnetic induction heater 3 is not in conta...

Embodiment 2

[0034] The difference between this embodiment and Embodiment 1 is that the width of the magnetic isolation block is 15 mm.

[0035] The frequency range of the supersonic frequency generated by the electromagnetic induction heater is 80KHZ.

Embodiment 3

[0037] The difference between this embodiment and Embodiment 1 is that the width of the magnetic isolation block is 10 mm.

[0038] The frequency range of the supersonic frequency generated by the electromagnetic induction heater is 30KHZ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com