Alloy constructional steel for large-scale wind power principal axis

A technology of alloy structural steel and wind power main shaft, which is applied in the field of wind power and can solve the problems that cannot be fully achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

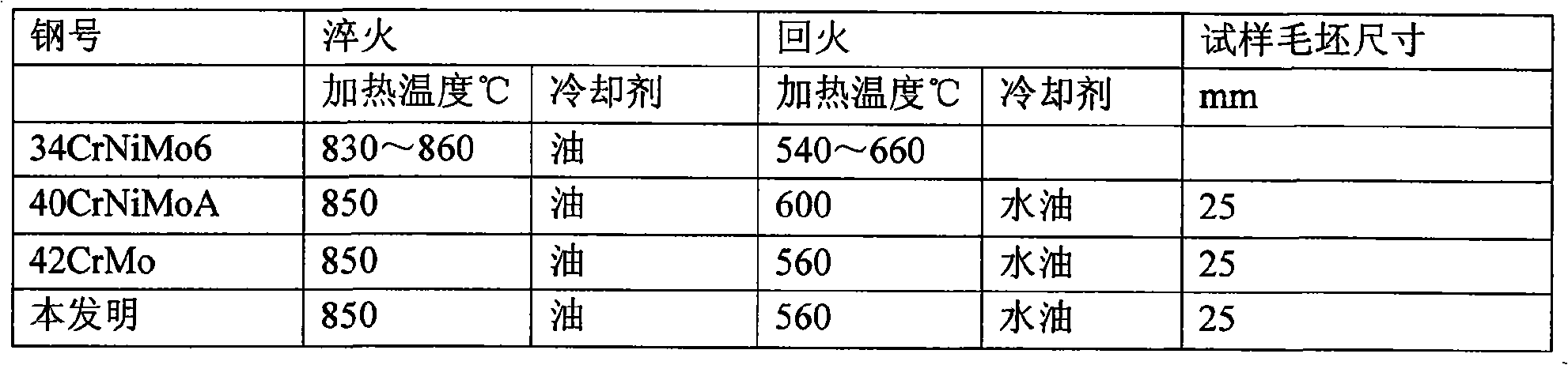

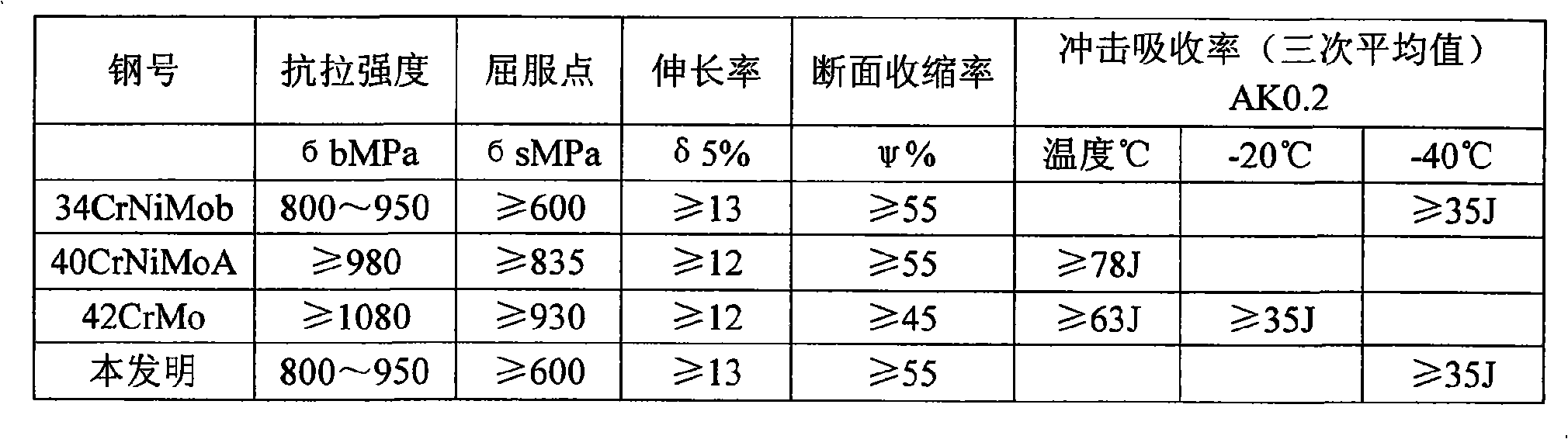

[0017] The invention relates to an alloy structural steel for a large-scale wind power main shaft, which is mainly composed of the following chemical components in weight percentage: C 0.38-0.45%, Si 0.17-0.37%, Mn 0.50-0.80%, Cr 0.90-1.20%, Ni 0.30 %, Mo 0.15-0.25%, P≤0.035%, S≤0.035%, and the balance is Fe and unavoidable impurities. For specific performance analysis, please refer to the attached table below.

[0018] Table 1: Comparison table of chemical composition

[0019] steel number

C

Si

mn

Cr

Ni

Mo

p

s

34CrNiMo6

0.32~

0.40

0.17~

0.37

0.40~

0.70

0.80~

1.10

1.55

0.15~

0.25

≤

0.025

≤

0.015

40CrNiMoA

0.37~

0.44

0.17~

0.37

0.50~

0.80

0.60~

0.90

1.25~

1.65

0.15~

0.25

≤

0.025

≤

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com