Water tank of splitting solar water heater

A solar water heater, split-type technology, applied in solar thermal power generation, fluid heaters, solar thermal devices, etc., can solve the problem of inconvenient and low water consumption, it takes a day or more to heat water in a water tank, and the heating cycle is long And other issues

Inactive Publication Date: 2008-10-29

江苏元升太阳能集团有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. The water tank of the split type solar water heater is generally a complete cavity. When in use, after tap water enters the water tank, the hot and cold water will have a mixed temperature phenomenon. Water needs a day or more, and the feature of long heating cycle is inconvenient to use water, wasting energy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

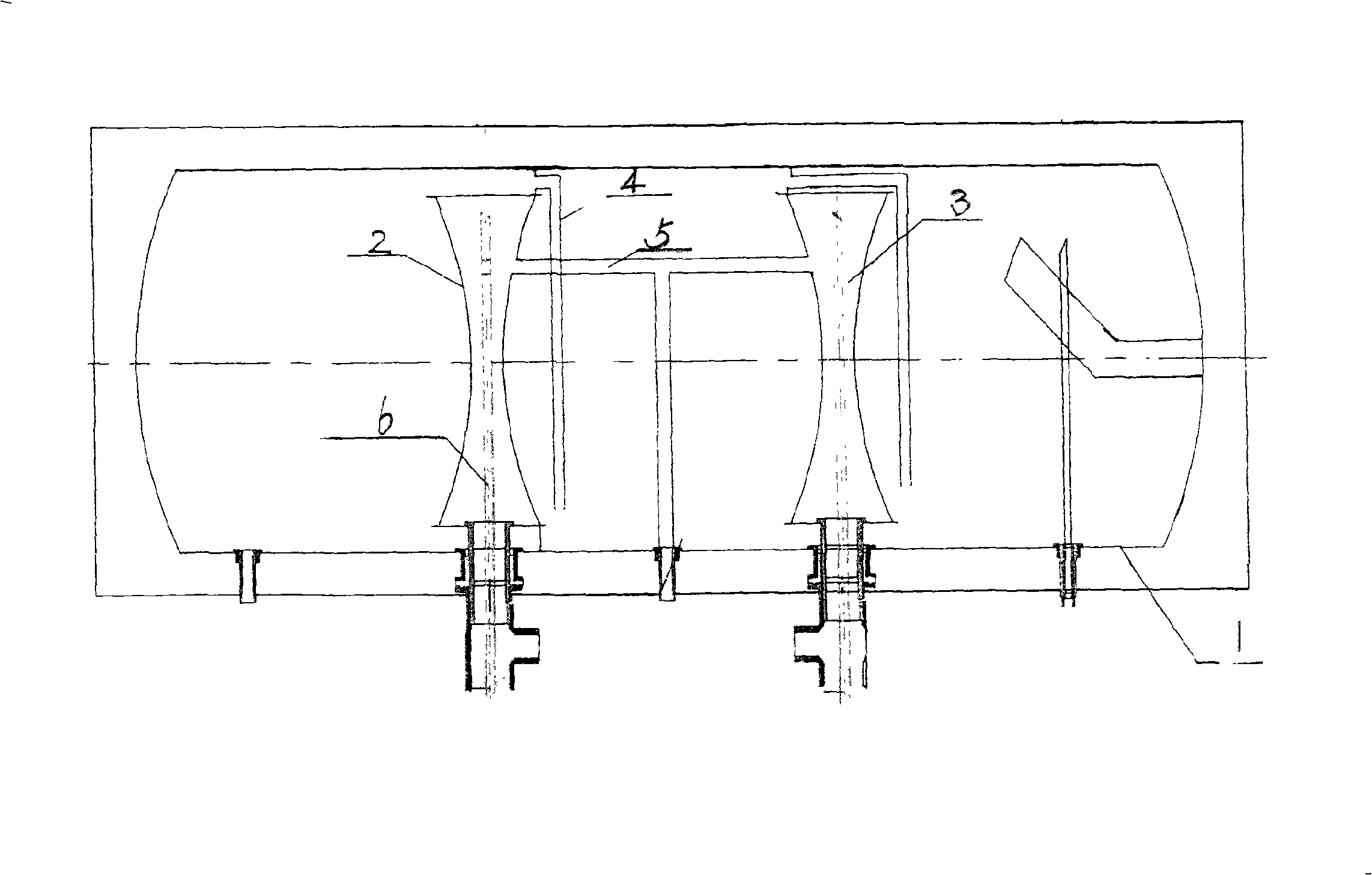

The invention discloses a divided water tank device for an internal heat exchanger of a split type solar water heater. Butt welding is carried out by utilizing an end enclosure of a stainless steel confined water bank inner bag; the end enclosure is used as the heat exchanger to play the role of a water tank partition board; the water tank is divided into independent divided cavities; the heat exchanger is sealed with the inner bag of the water tank; the adjacent cavity bodies communicate with each other via draught tubes; the medium circulation and the medium supplement, namely unconfined running of the heat exchanging part, are carried out safely and reliably via an upper circulating pipe and a heat collecting part; and the device can fully improve heat energy transformation and reduce heat loss.

Description

Water tank of a split type solar water heater technical field The invention relates to a solar water heater, in particular to a separate-cavity water tank with a built-in heat exchanger of a split solar water heater. Background technique 1. The water tank of the split type solar water heater is generally a complete cavity. When in use, after tap water enters the water tank, the hot and cold water will have a mixed temperature phenomenon. Water needs one day or more, and the characteristics of long heating cycle are very inconvenient to use water and waste energy. 2. This invention solves the problem of how to use a pressurized solar water tank in combination with a non-pressurized solar collector. The hot water used is pressurized (to solve the problem of automatic water supply), while the heat exchange part is not under pressure , can use non-pressurized vacuum tube solar collectors, do not need to use expensive collectors such as "heat pipes" or "U" shaped tubes, which...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F24J2/46F24H9/00

CPCY02E10/40

Inventor 吴道元

Owner 江苏元升太阳能集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com