Helical energy-saving lamp and production method

A production method and technology of energy-saving lamps, applied in the manufacture of discharge tubes/lamps, discharge lamps, gas discharge lamps, etc., can solve the problems of short life of spiral energy-saving lamps, poor powder coating quality, etc., and achieve uniform phosphor powder layer , quality improvement, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

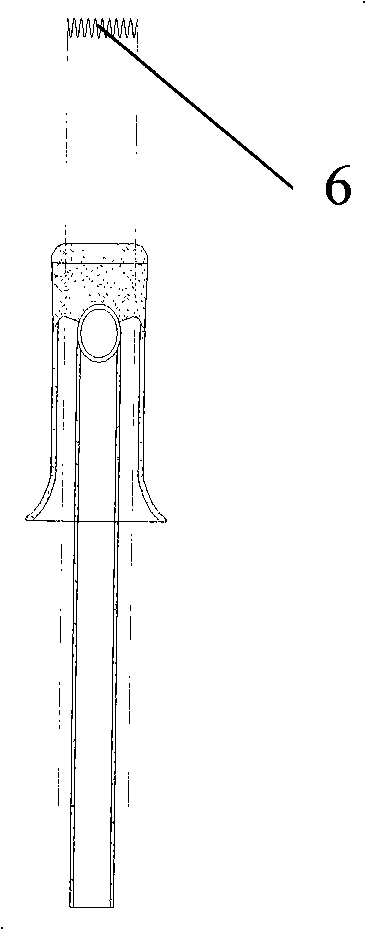

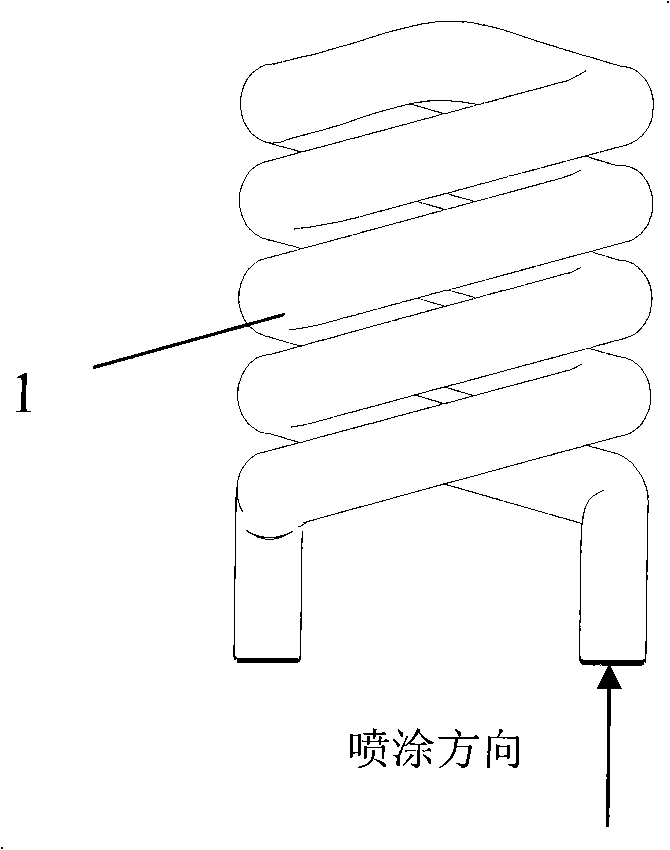

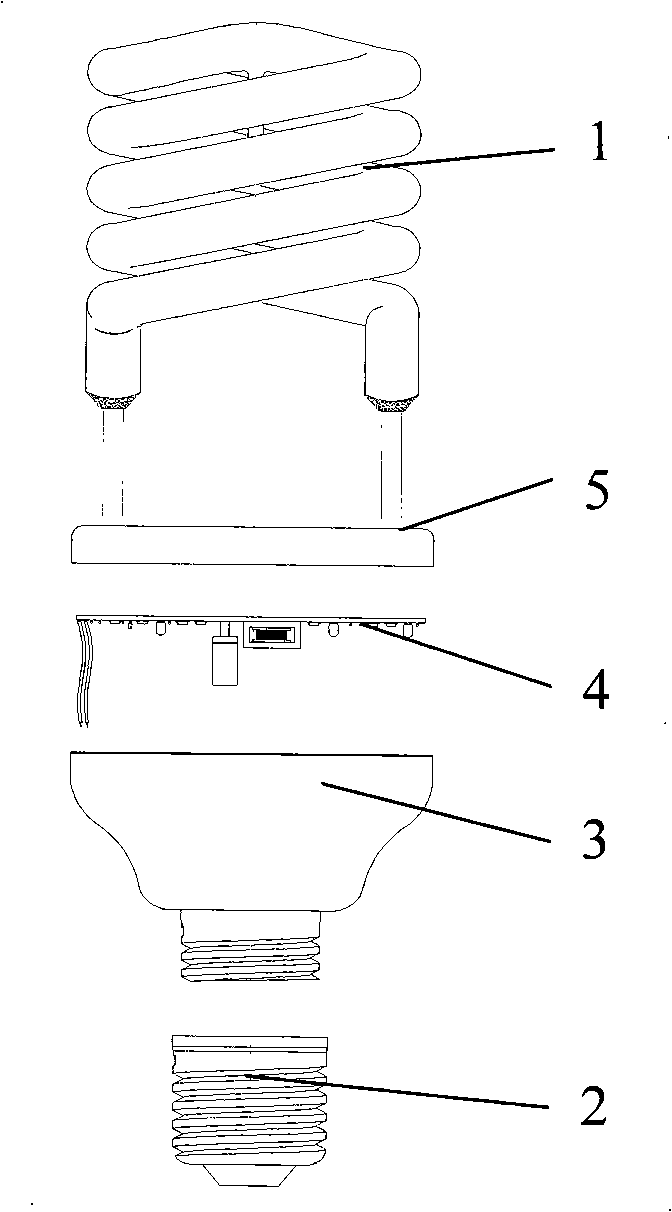

[0033] The spiral type energy-saving lamp such as image 3 Figure 12 As shown, it includes a spiral lamp tube 1, a lamp cap 2, a base 3, an electronic rectifier 4 and a connector 5, the electronic rectifier 4 is arranged in the base 3, the base 3 is fixedly connected to the lamp cap 2, and the two parts of the electronic rectifier 4 and the lamp cap 2 The two electrodes are connected, the spiral lamp tube 1 is connected with the base 3 through the connecting piece 5, and a filament 6 is respectively arranged at both ends of the spiral lamp tube 1, and it is characterized in that: the filament 6 is connected with the electronic rectifier 4 through the guide wire 7, and the guide wire 7 Glass beads 8 are sleeved on the top, and the filament 6 is arranged along the axial direction of the spiral lamp tube 1 .

[0034] The manufacturing method of the spiral energy-saving lamp comprises the following steps:

[0035] 1. Cut the glass tube to the desired length, and bend it into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com