Method for processing printed circuit board

A technology for printed circuit boards and processing methods, which is applied to the formation of electrical connection of printed components, multi-layer circuit manufacturing, etc. The effect of uniform metal layer and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention discloses a processing method of a printed circuit board, and the processing steps of a preferred embodiment thereof will be introduced below with reference to the accompanying drawings.

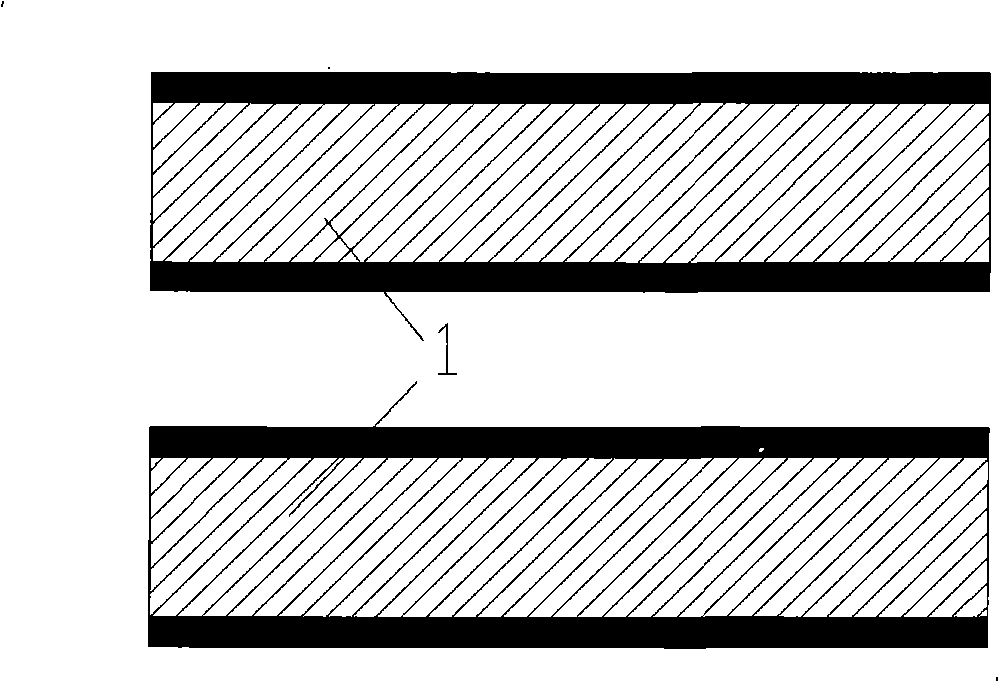

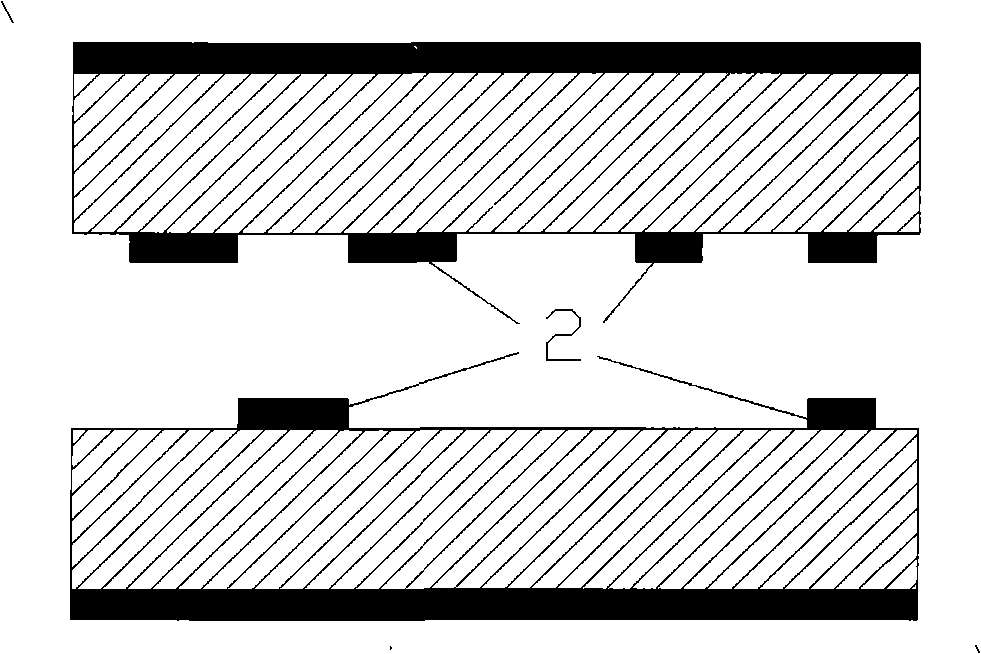

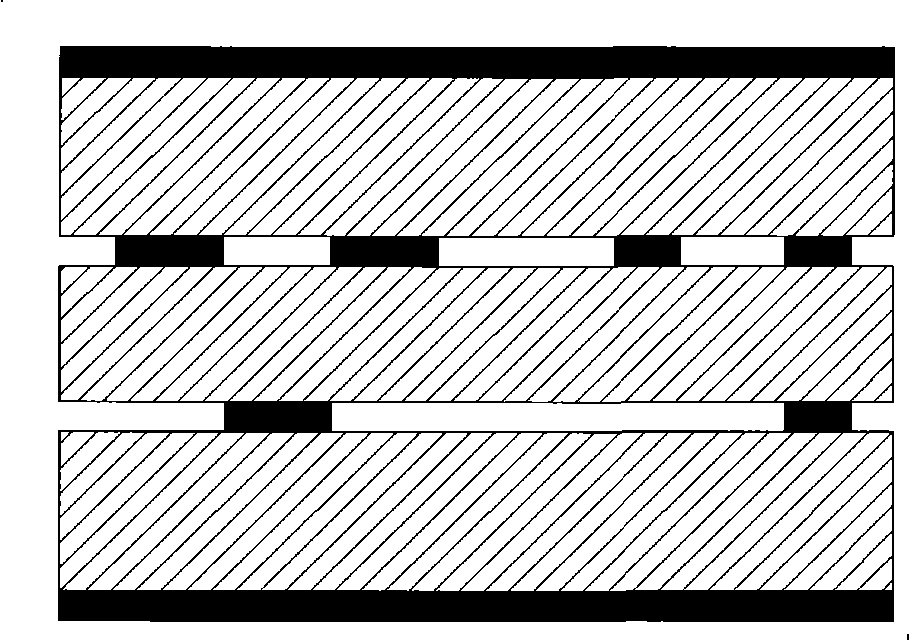

[0027] Such as Figure 1b , first choose two double-sided insulating substrates 1; Figure 2b , using mechanical drilling to process and form through-holes 4 on a single insulating substrate; for example Figure 3b , electrodeposit copper 5 in the through hole of the insulating substrate; as Figure 4b , processing and forming lines 2 on the opposite surfaces of the two substrates; for example Figure 5b , place a new insulating substrate in the middle of the two substrates for lamination processing to form an integral multilayer printed circuit board; such as Figure 6b , using mechanical drilling to process and form the through hole 4 on the multi-layer printed circuit board; for example Figure 7b , electrodepositing copper 5 in the through-hole of the multilayer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com