Radial piston-type hydraulic motor with cylinder block cooling

A technology of hydraulic motor and cylinder block, applied in the field of hydraulic motor, can solve problems such as high risk of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

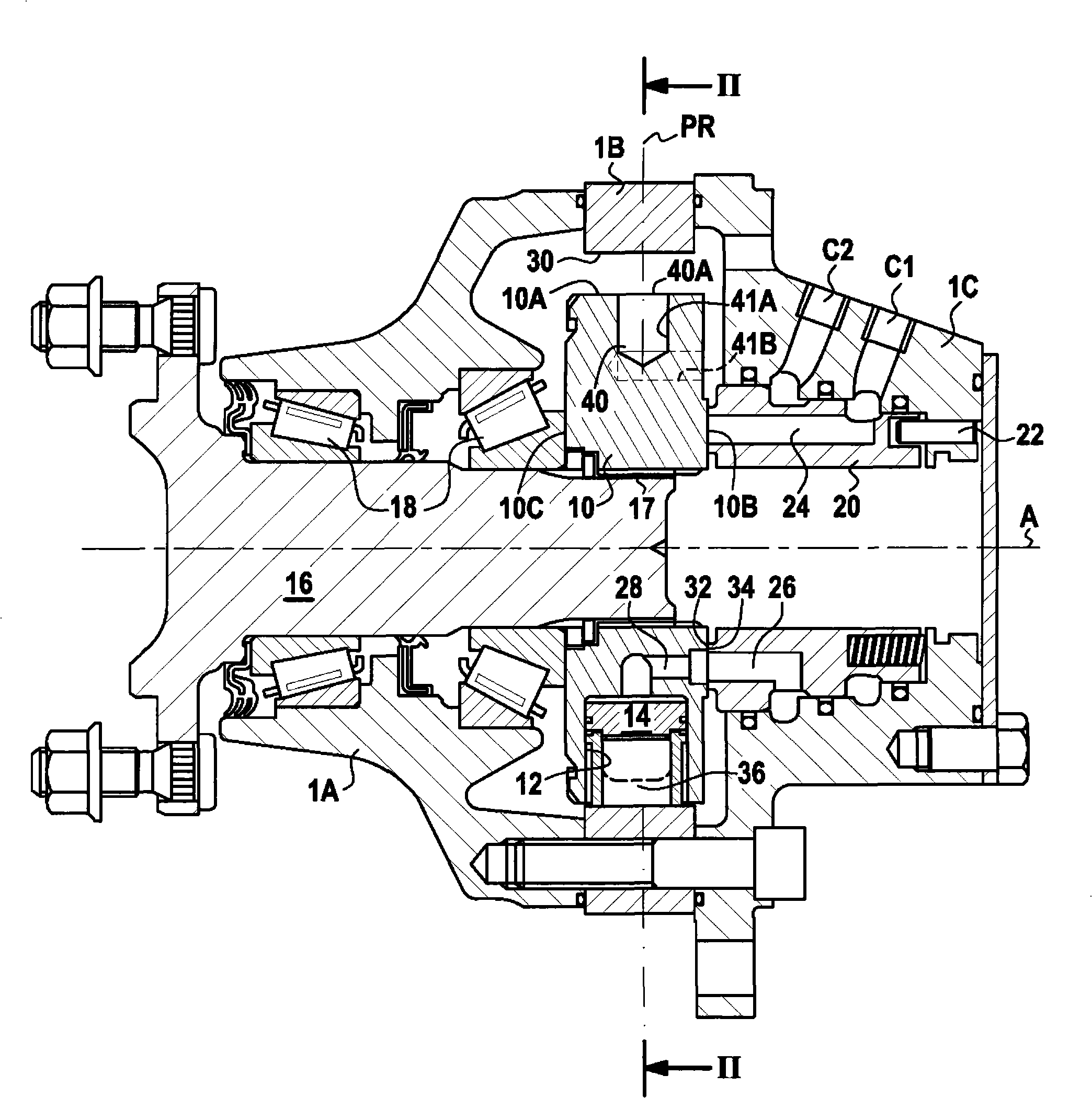

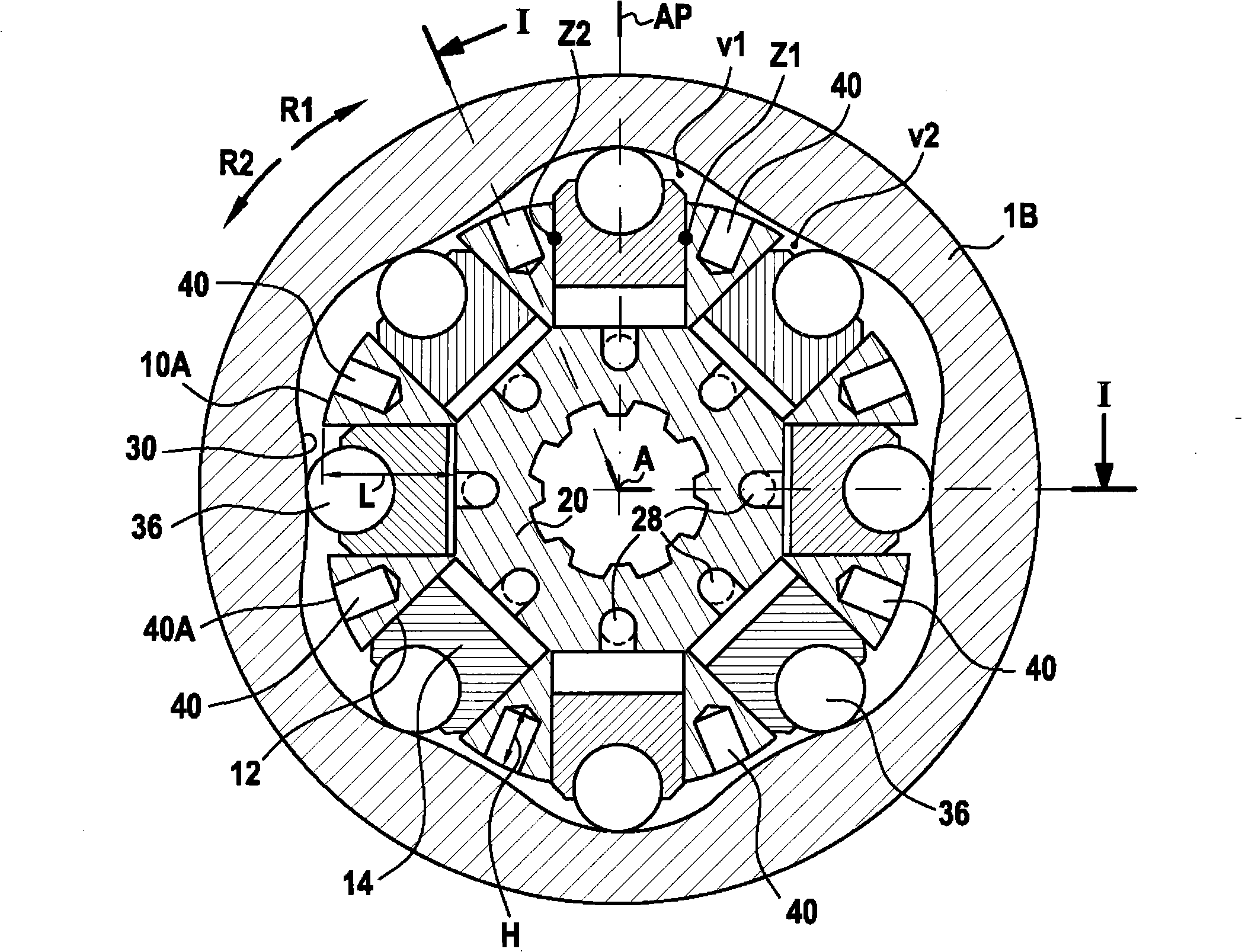

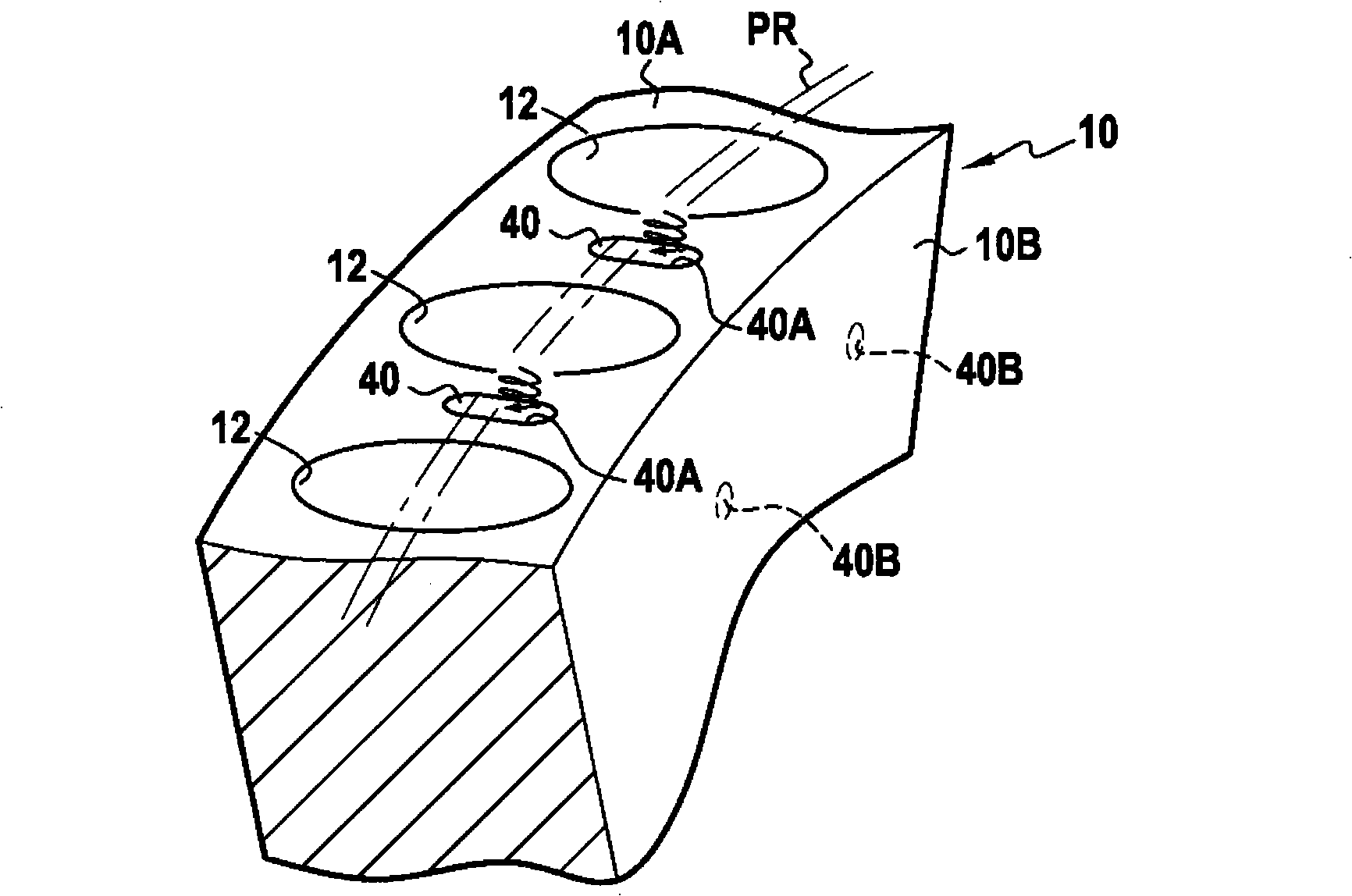

[0040] figure 1 The hydraulic motor shown has a housing comprising three parts 1A, 1B and 1C. A cylinder block 10 including a plurality of cylinders 12 in which pistons 14 are slidably mounted is provided in the housing. The motor is a motor with a radial piston, and the cylinder is arranged at a certain angle in the radial direction around a rotation axis A, and the cylinder body and the outer casing rotate relative to each other around the rotation axis A.

[0041] In this example, the housing is fixed and the cylinder block moves, and as the cylinder block rotates, it rotates to drive the output shaft 16 , which is constrained by slots 17 to rotate with the cylinder block. Said rotation relative to the housing is supported by bearings 18 . Also provided in the housing is a fluid distributor 20 which is fastened to the housing by stud and notch arrangement 22 and is prevented from rotating relative to the housing. The distributor is provided with distribution conduits 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com