Anti-rotten method for culturing pea nuts in plain covered by overlay film

A peanut and film-covering technology, which is applied in the agricultural field, can solve the problems of blocked soil surface water evaporation, poor soil permeability of the cultivated layer, and reduced field evaporation, so as to increase field evaporation, reduce rotten fruit rate, and fruit full rate. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

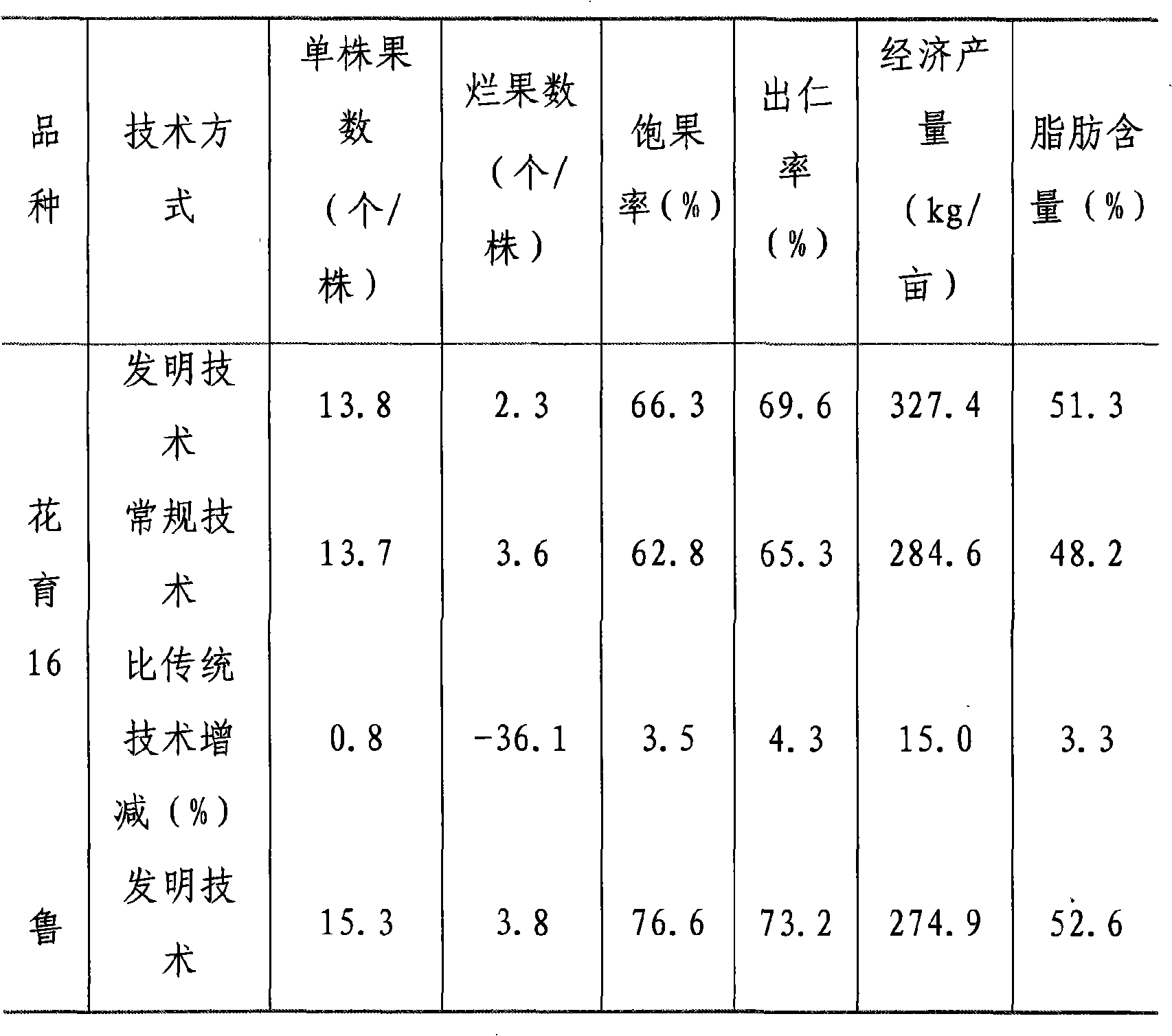

Embodiment 1

[0016] (1), conventional cultivation method:

[0017] Ridging on flat ground, ridge height 10cm; ridge spacing 85cm-90cm, ridge surface width 55cm-60cm, 2 rows of sowing ditch on the ridge for sowing, row spacing 35cm-40cm, and then mulching, mulching throughout the entire growth period (from sowing to harvest).

[0018] (2), cultivation method of the present invention:

[0019] Ridging on flat ground, ridge height 14cm; ridge distance 85cm-90cm, ridge width 55cm-60cm, 2 rows of sowing ditch are opened on the ridge for sowing, the row spacing on the ridge is 35cm-40cm, and then covered with film, and the ridges are sealed before a large number of peanuts are buried in the soil. Before that, the film will be unveiled on July 8.

[0020] Described peeling film specifically comprises the following steps:

[0021] (1) Cutting the mulch film on the peanut ridge surface: directly use a sickle to cut the mulch film on the peanut ridge surface, and cut two lines. Note that the cut...

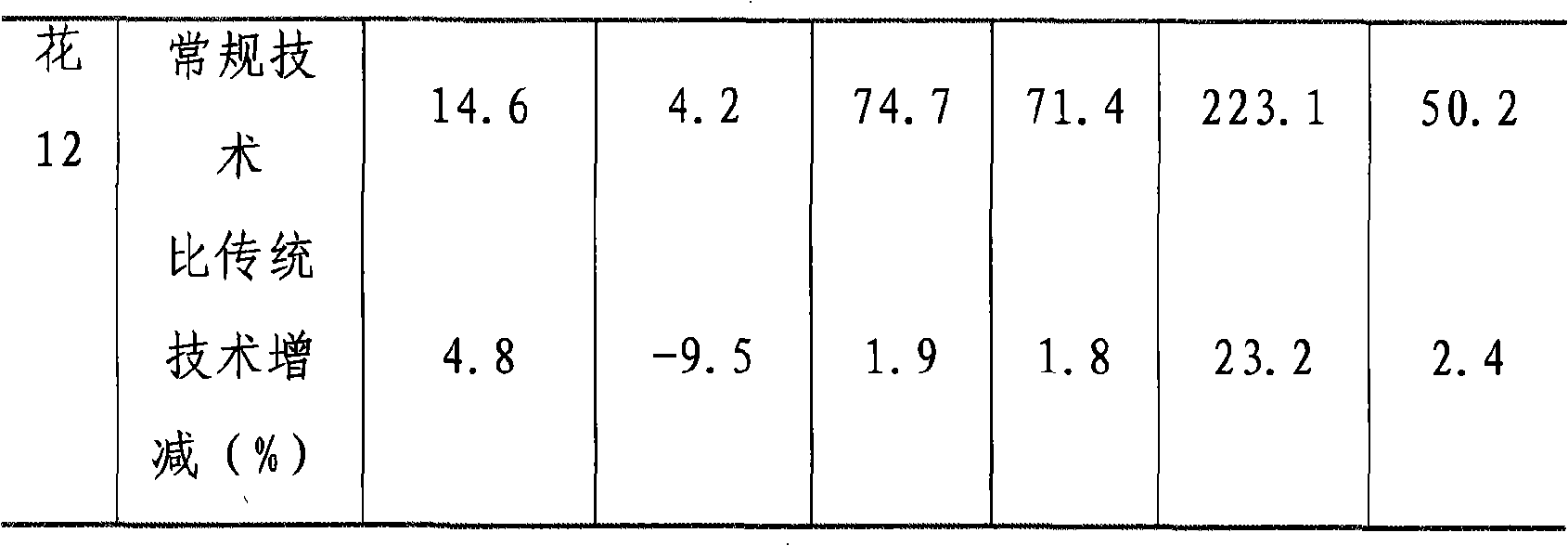

example 2

[0030] (1), conventional cultivation method:

[0031] Ridging on flat ground, ridge height 12cm; ridge spacing 85cm-90cm, ridge surface width 55cm-60cm, 2 rows of sowing ditch are opened on the ridge for sowing, the row spacing on the ridge is 35cm-40cm, and then covered with film, the mulch covers throughout the entire growth period (from sowing to harvest).

[0032] (2), cultivation method of the present invention:

[0033] Ridging on flat ground, ridge height 15cm; ridge distance 85cm-90cm, ridge width 55cm-60cm, 2 rows of sowing ditch are opened on the ridge for sowing, the row spacing on the ridge is 35cm-40cm, and then covered with film, and the ridges are sealed before a large number of peanuts are buried in the soil. Before that, the film will be unveiled on July 10.

[0034] Described peeling film specifically comprises the following steps:

[0035] (1) Cutting the mulch film on the peanut ridge surface: directly use a sickle to cut the mulch film on the peanut rid...

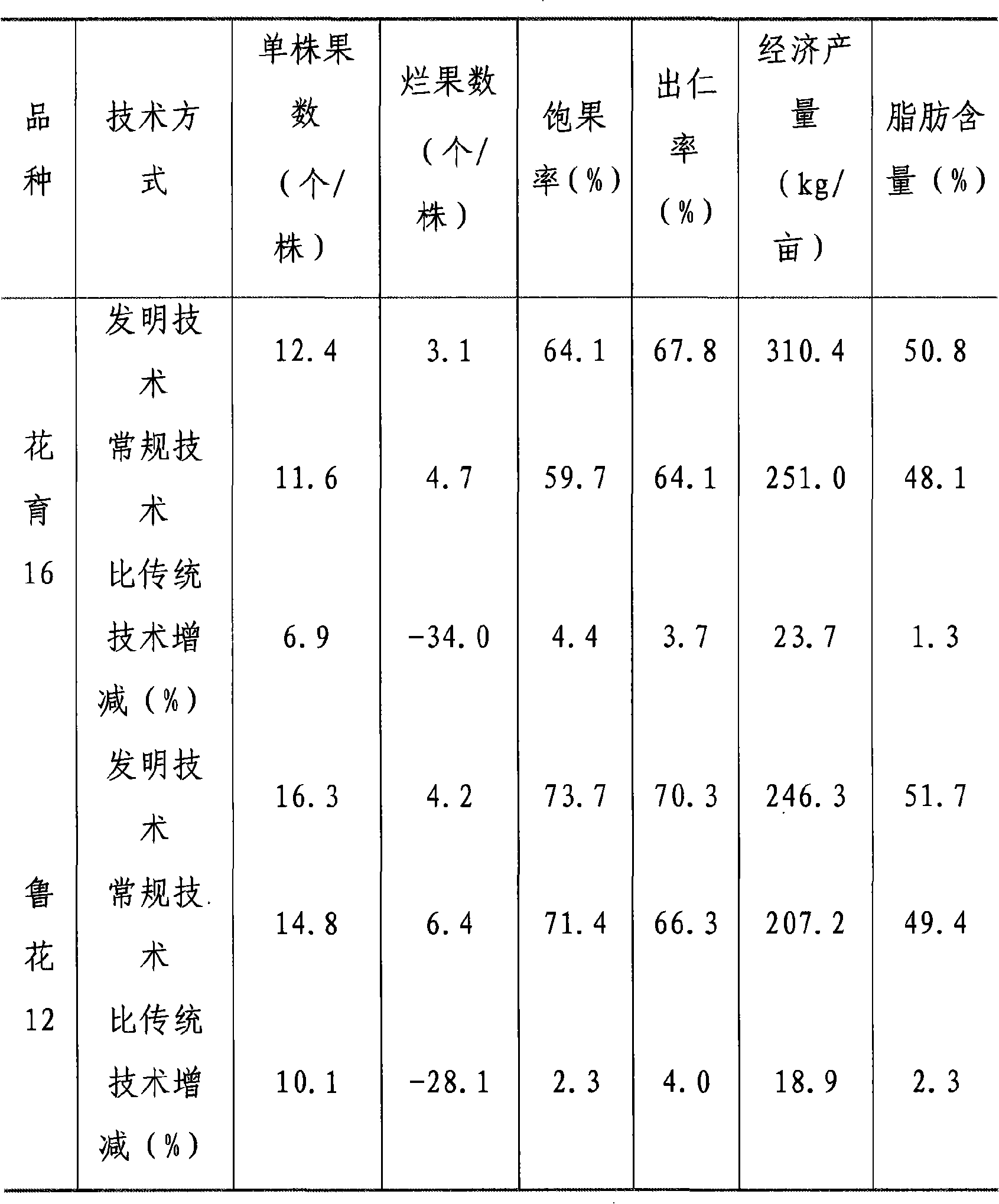

example 3

[0043] (1), conventional cultivation method:

[0044] Ridging on flat ground, ridge height 11cm; ridge spacing 85cm-90cm, ridge surface width 55cm-60cm, 2 rows of sowing ditch are opened on the ridge for sowing, the row spacing on the ridge is 35cm-40cm, and then covered with film, the mulch covers throughout the entire growth period (from sowing to harvest).

[0045] (2), cultivation method of the present invention:

[0046] Ridging on flat ground, ridge height 15cm; ridge distance 85cm-90cm, ridge width 55cm-60cm, 2 rows of sowing ditch are opened on the ridge for sowing, the row spacing on the ridge is 35cm-40cm, and then covered with film, and the ridges are sealed before a large number of peanuts are buried in the soil. Before that, the film will be unveiled on July 3.

[0047] Described peeling film specifically comprises the following steps:

[0048] (1) Cutting the mulch film on the peanut ridge surface: directly use a sickle to cut the mulch film on the peanut ridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com