Co-injection molding apparatus

A molding device and co-injection technology, which is applied in the field of plastic product molding, can solve problems affecting the uniformity and surface quality of products, and achieve the effects of small changes in resin flow rate and pressure, improved uniformity and bonding strength, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

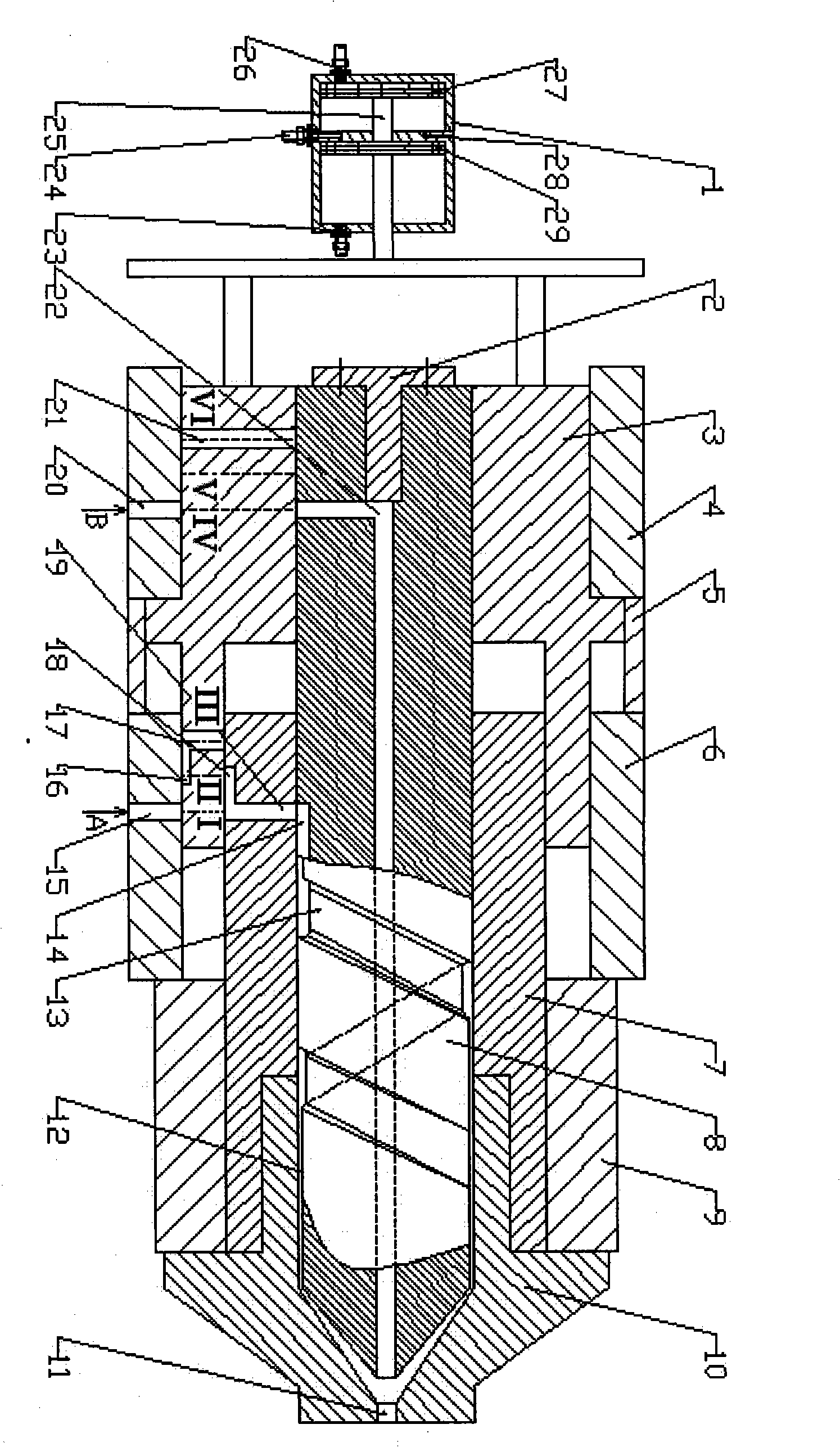

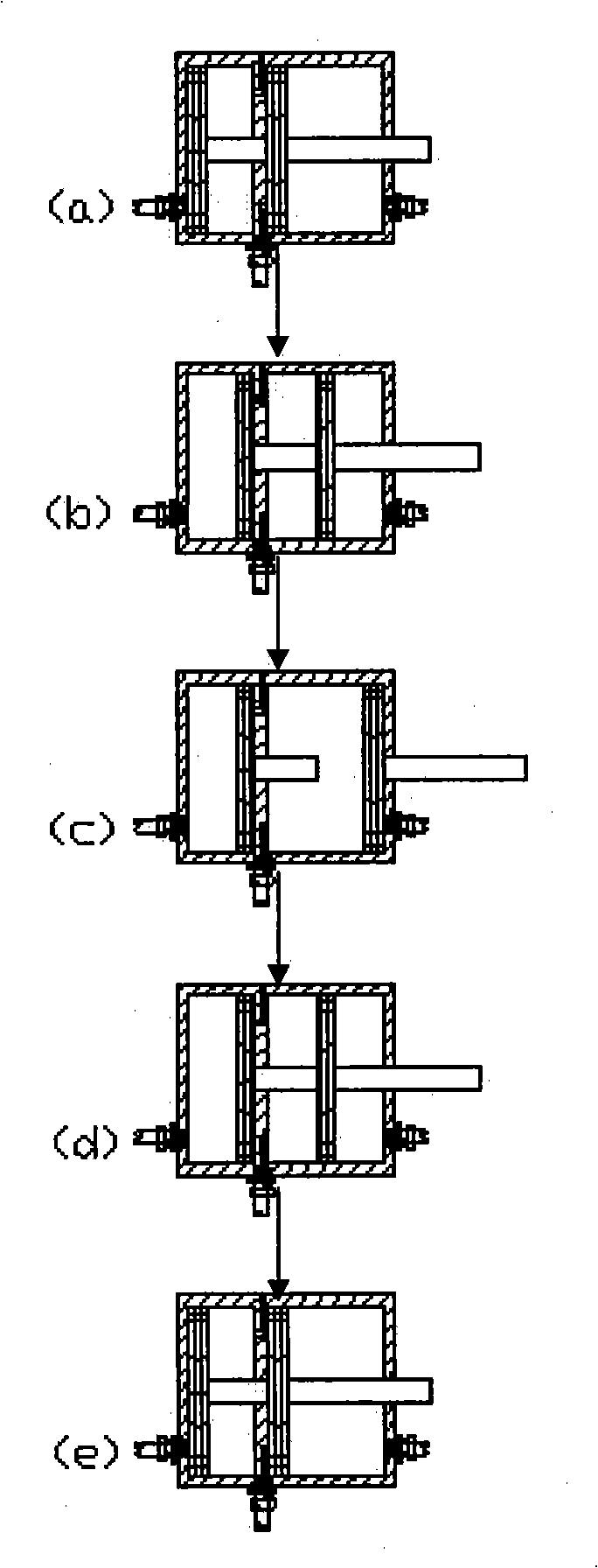

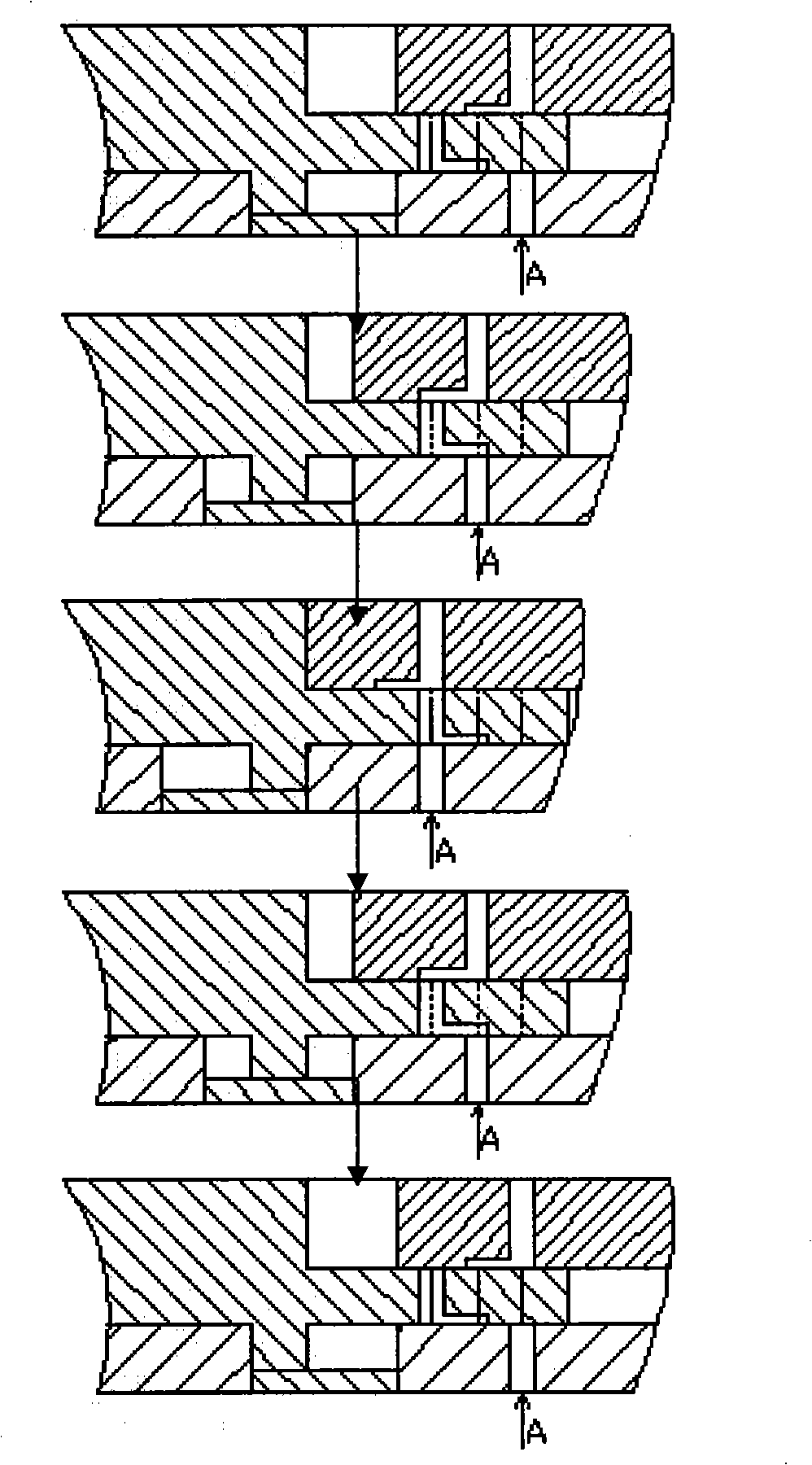

[0016] Before starting work, the unit is positioned at figure 1 location. The outer resin A is injected from the flow channel 15, and the inner layer resin B is injected from the flow channel 20. At this time, the I position of the middle slider 3 is at the flow channel 15, and the position IV is at the flow channel 20. Start to work, release the gas at the right end of the right cylinder from the gas port 23, and inject gas from the gas port 26, push the piston 27 to move forward to the right part of the left cylinder, make the piston 27 move forward for a certain distance, and push the middle slider 3 to move forward, Make the position II of the middle slider 3 reach the runner 15, and the V position reach the runner 20, the lateral opening 16 of the runner 17 is connected with the outer resin runner 15, and the lateral opening of the runner 17 and the runner 19 18 are connected, thereby connecting the outer layer resin flow channel, while the inner layer resin flow channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com