Steam heating corrugated roller of single face corrugation making machine

A technology for corrugating machines and corrugating rollers, applied in the field of corrugating rollers, can solve the problems of waste of rollers, troublesome installation or roller replacement, and inability to discharge condensed water, and achieve the effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

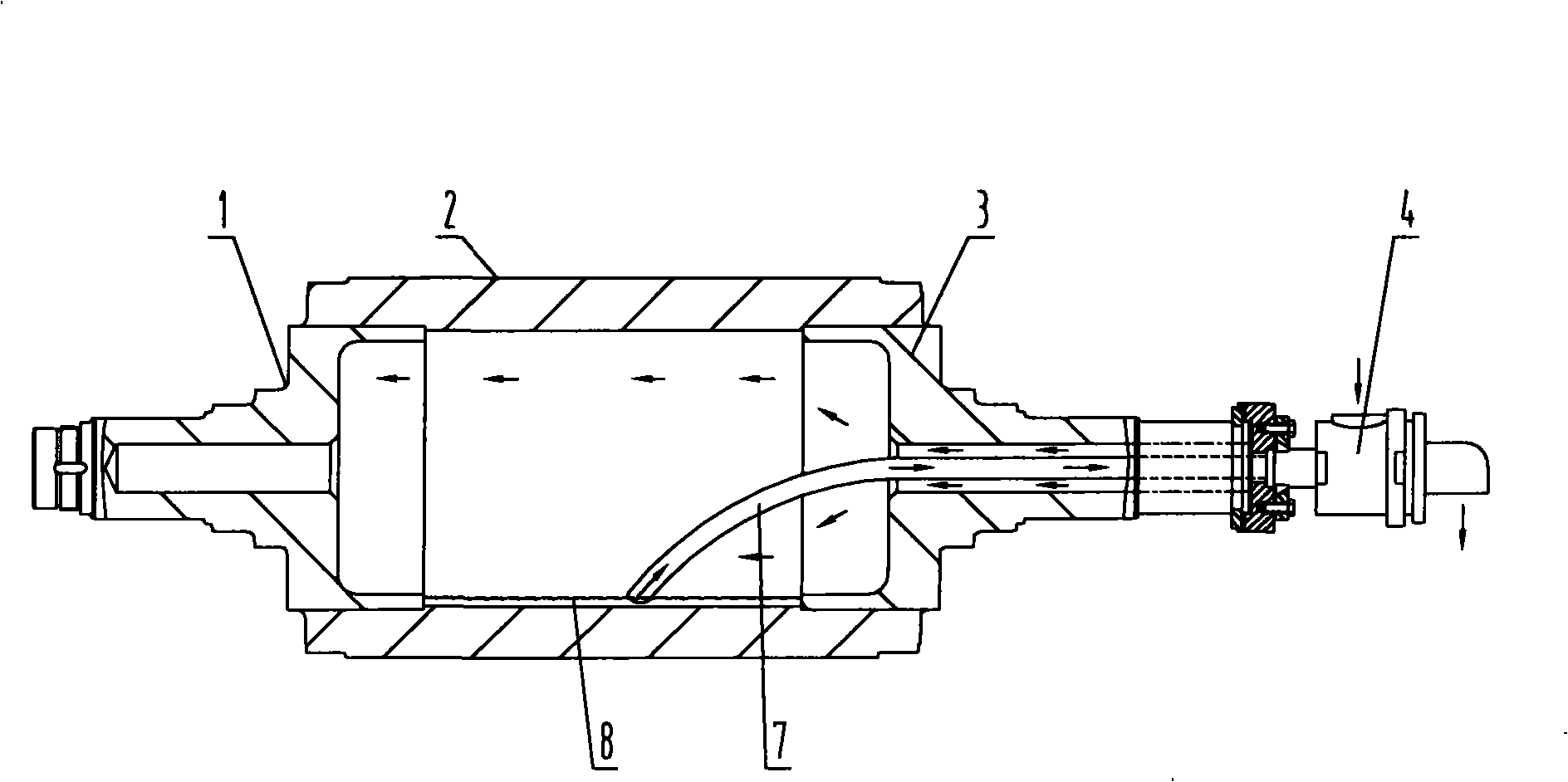

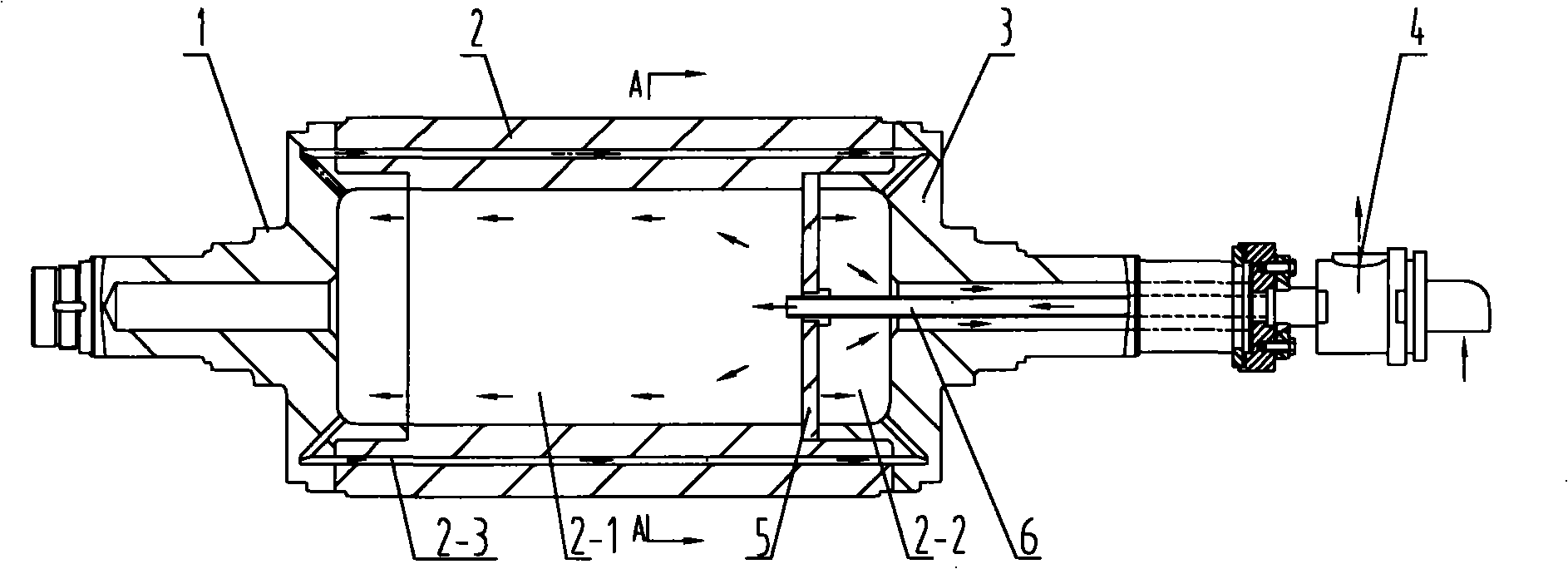

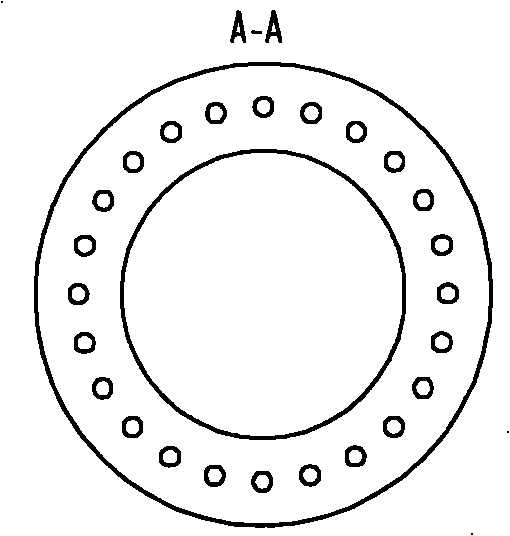

[0008] In the original corrugated roll (see figure 1 ) directly on the surface, remove the siphon, and uniformly process a week of heat conduction holes around the roller (see figure 2 ), the steam chamber and the condensation chamber are divided into a steam chamber and a condensation chamber in the cylinder through a partition. The steam chamber is 8-10 times larger than the condensation chamber. The chamber communicates with the condensed water outlet in the right half shaft, the inlet end of the steam circulation heat conduction hole communicates with the steam chamber, and the outlet end communicates with the condensation chamber (see image 3 ).

[0009] Working mode: The saturated steam is introduced into the steam chamber through the steam pipe, and the steam in the steam chamber enters the heat conduction hole to heat the roller. In this way, the steam cavity and the heat conduction holes are fed with steam, which increases the heat exchange area, rapidly heats the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com