Laminating encapsulant film containing phosphor over leds

A phosphor and sealant technology, applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of inconsistent color temperature, complexity of phosphor deposition process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

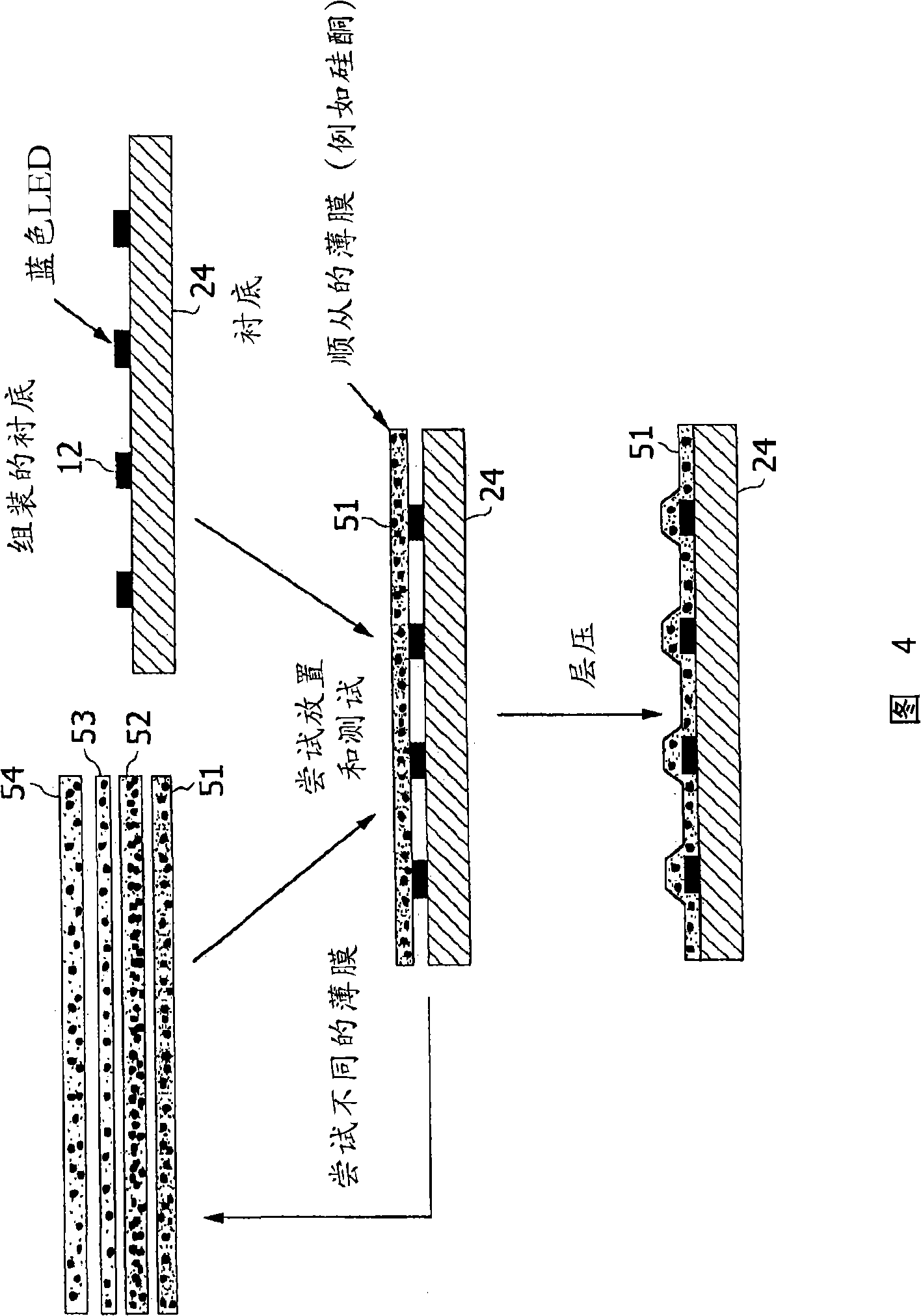

[0024] 5 is a flowchart illustrating one embodiment of a method for wavelength conversion of LED light to produce a uniform output CCT despite LEDs emitting light having different color temperatures.

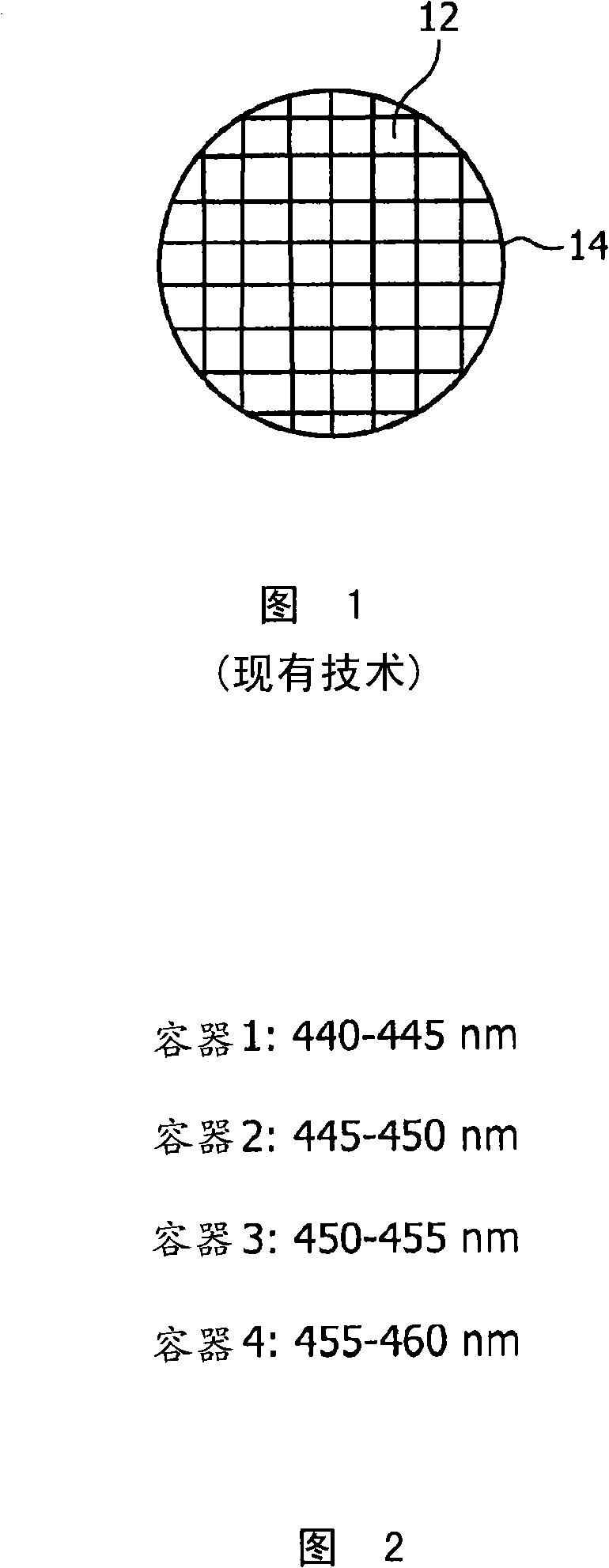

[0025] In step 10 of Figure 5, LEDs are formed on the wafer in a conventional manner. FIG. 1 is a front view of LED 12 formed on growth wafer 14 . In one embodiment, the growth wafer is sapphire, GaN or SiC, and the LEDs are CaN-based LEDs that emit blue or UV light. In other embodiments, the LED and growth substrate can be of any type. GaN-based LEDs are particularly suitable for forming blue or UV LEDs that are frequently used in combination with phosphors for wavelength conversion.

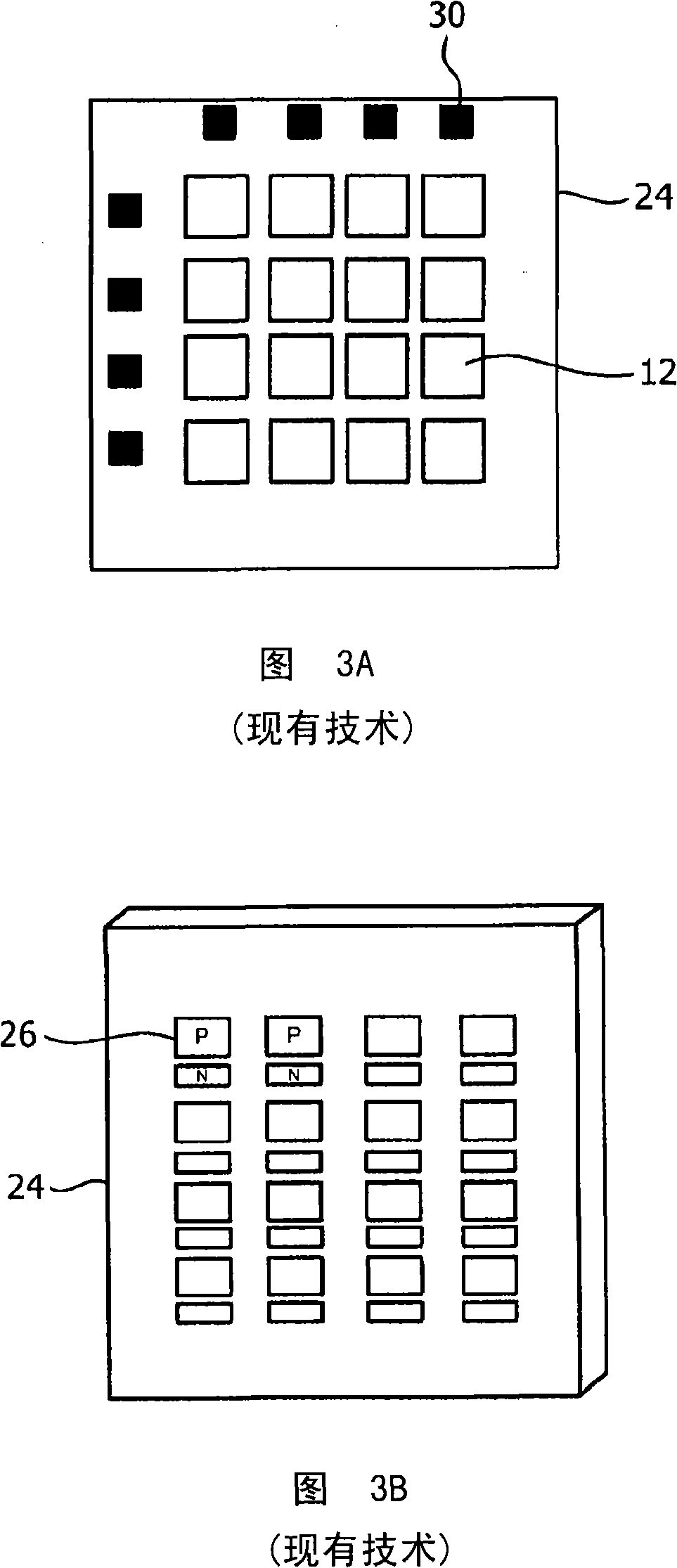

[0026] In step 16 of Figure 5, the individual LEDs are probed to energize each LED. A color detector measures the peak wavelength of light emitted from each LED. In this example, the measured color of the LED falls into one of four color ranges. Each scope is called a container. In one exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com