Method and device for coating a surface

A technology of coating and equipment, applied in the direction of printing devices, printing, typewriters, etc., can solve the problems of not being realistic enough or real, and achieve the effect of highly flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

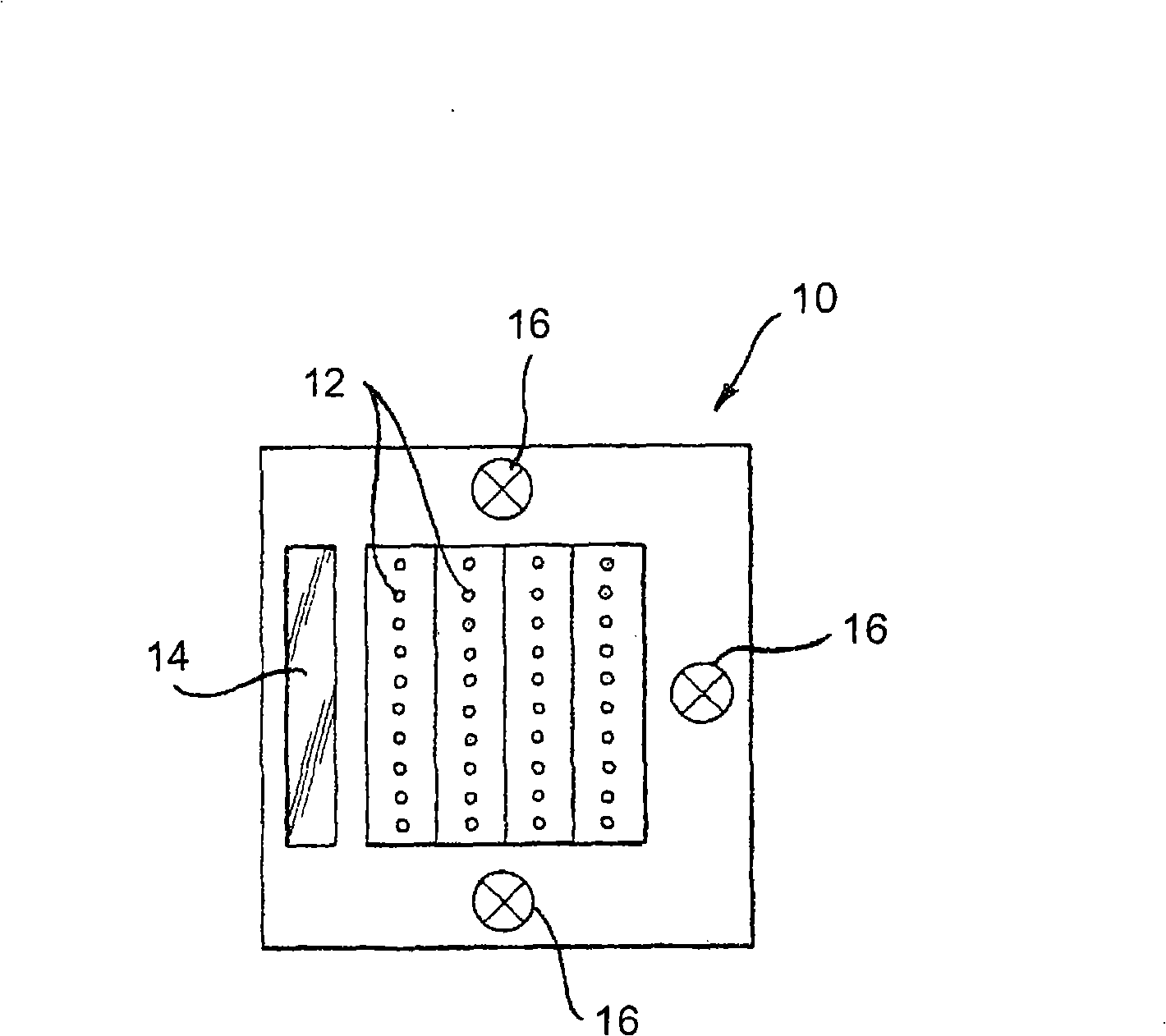

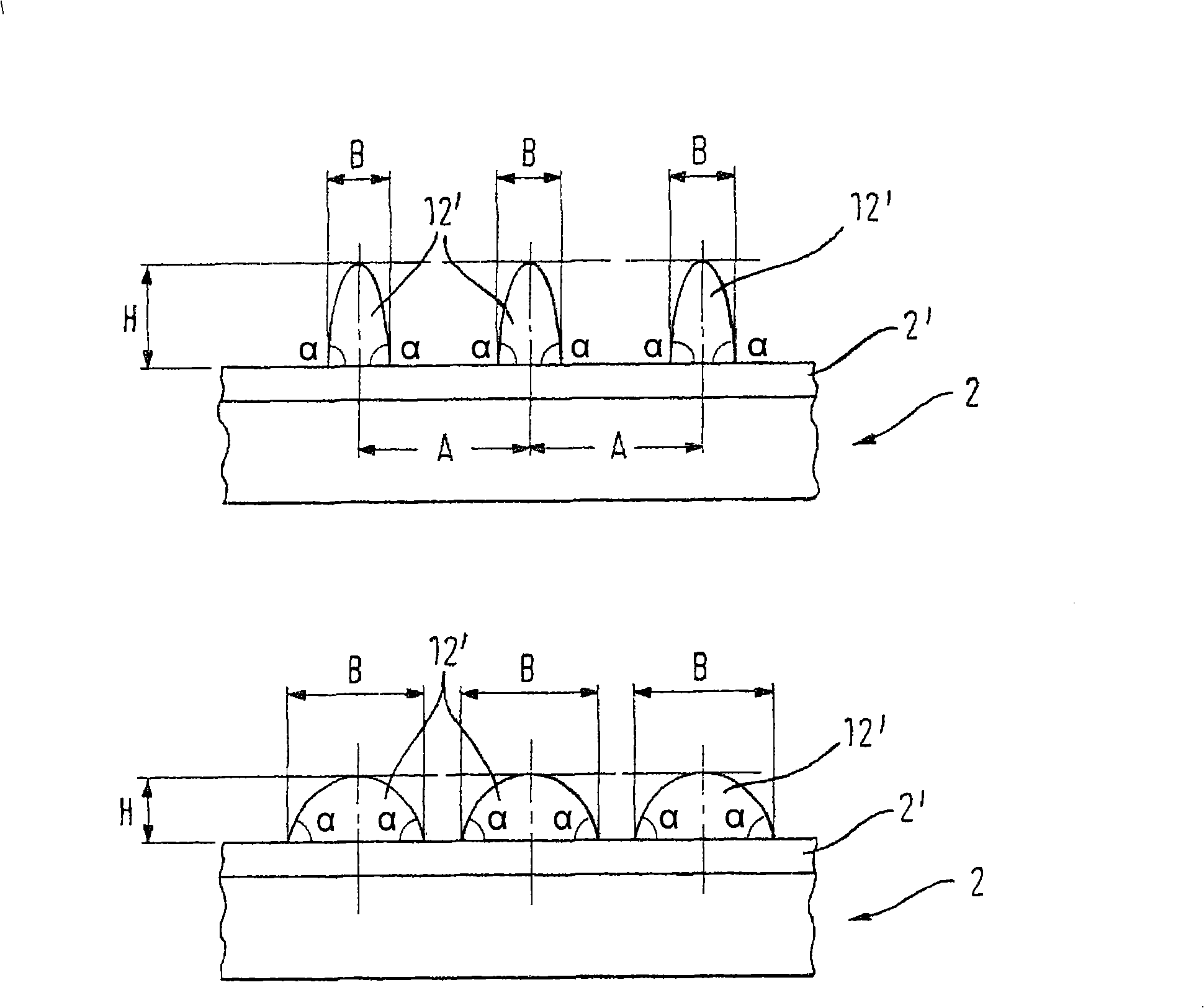

[0022] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

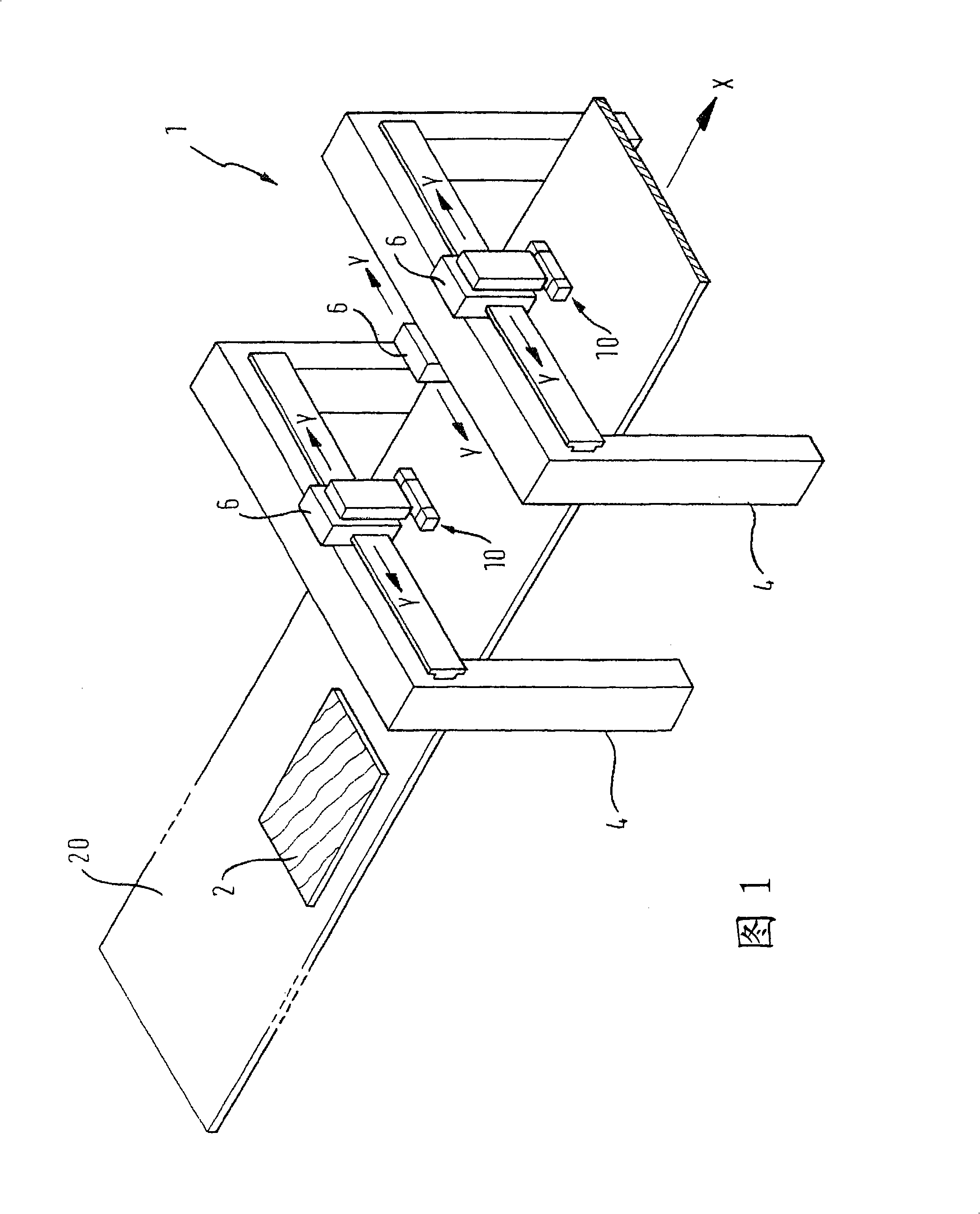

[0023] FIG. 1 schematically shows a device 1 according to the invention for coating the surface of an object 2 as a preferred embodiment of the invention. The object 2 to be coated can be, for example, a plate-shaped or strip-shaped workpiece frequently used in the furniture industry and preferably at least partially consists of wood, wooden materials, plastic materials or the like. However, it should be noted that the invention is also applicable to other types of workpieces or items.

[0024] The plant 1 firstly has a conveyor device 20 which can be designed, for example, in the form of a conveyor belt, a conveyor table, a conveyor chain, or the like. In this embodiment, two portal frames 4 are arranged above the conveying device 20 , and the portal frames 4 can also be configured as cantilevers (jib) or the like, for example. At least one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com