Postposition type sloped rotating paddle wind turbine

A tilt-rotating, wind turbine technology, applied in wind turbines, wind turbine components, wind turbines that are in the same direction as the wind, etc., can solve the problems of large horizontal thrust of vertical columns, high cost, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

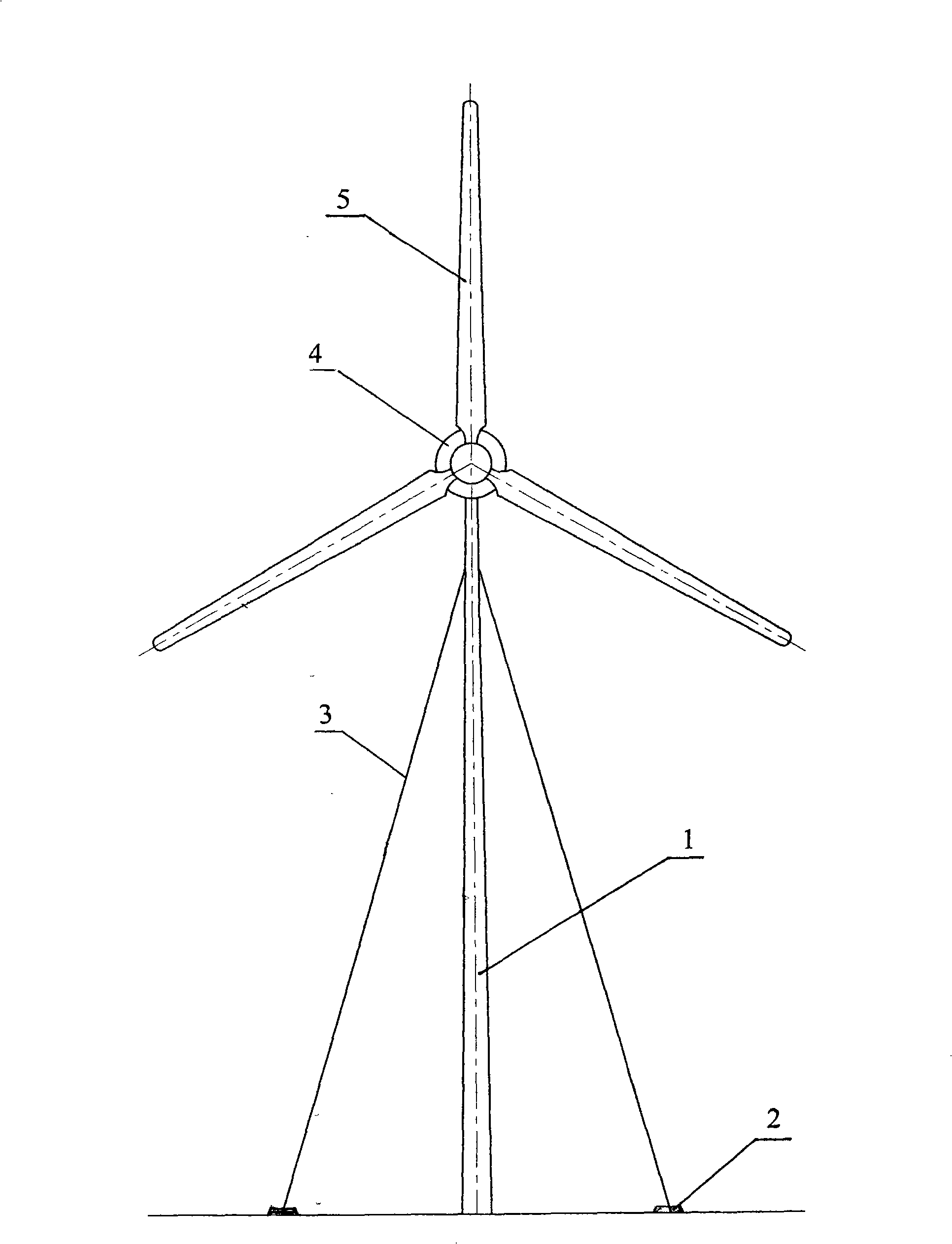

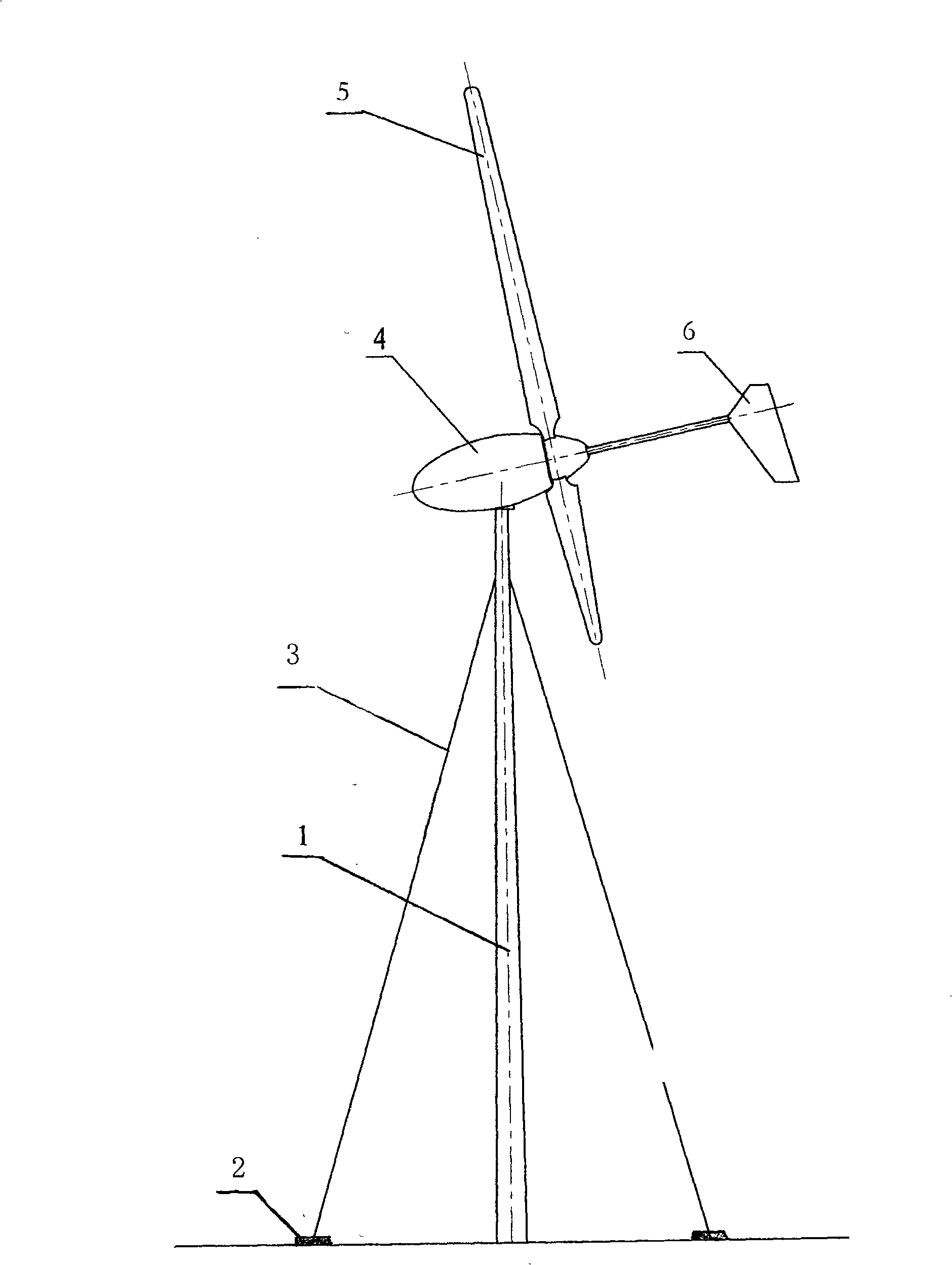

[0011] The column 1 of the present invention is vertically installed on the ground, with the root of the column 1 as the center, three ground piles 2 are arranged at equal distances around the root of the column 1, and cable-stayed steel cables 3 are arranged between the ground piles 2 on the top of the column 1. The top of 1 is inclined to set the wind turbine nacelle 4 and the equipment in the cabin. The angle between the axis of the wind turbine nacelle 4 and the ground is 30°. The wind turbine nacelle 4 rotates with an oblique axis, and the end of the wind turbine nacelle 4 behind the blade 5 is provided with a wind direction tail rudder 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com