Magnetic suspension paddle distance self-adjusting vertical shaft wind power generator

A technology of wind power generators and magnetic levitation, which is applied in the direction of wind power generators, wind power motor combinations, wind power generators at right angles to the wind direction, etc. It can solve problems such as poor wind resistance, complex structure, and increased driving force of the transmission drive system, and achieve The effect of reducing starting resistance torque, improving power generation efficiency, and increasing output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

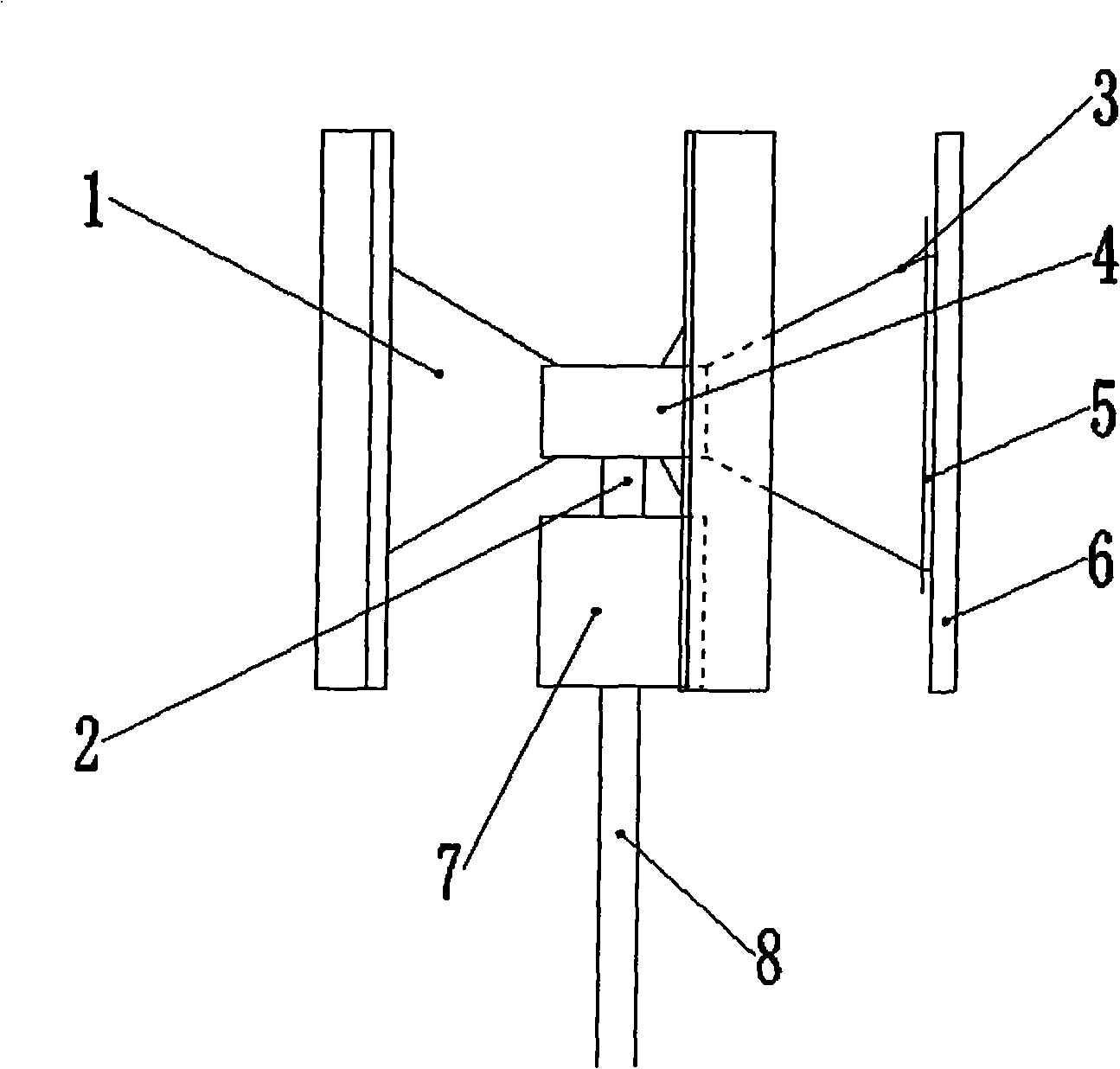

[0027] figure 1 Among them, the generator shaft 16 of the magnetic levitation wind power generator is made integrally with the impeller shaft 2 of the impeller 1, the generator shaft 16 penetrates into the motor housing 13, and the generator rotor 12 is installed on the generator shaft 16, corresponding to The generator stator 11 is arranged on the motor casing 13 of the motor, and the impeller 1 includes a plurality of blades 6, and each blade 6 is connected with a vertical vertical rod 5 through a hinge, and the vertical rod 5 is connected with two connecting rods 3, and the three become Triangular; two connecting rods 3 are fixed on the hub 4, and the hub 4 is fixedly connected with the impeller shaft 2 and drives it to rotate. The generator 7 is mounted on a tower 8 .

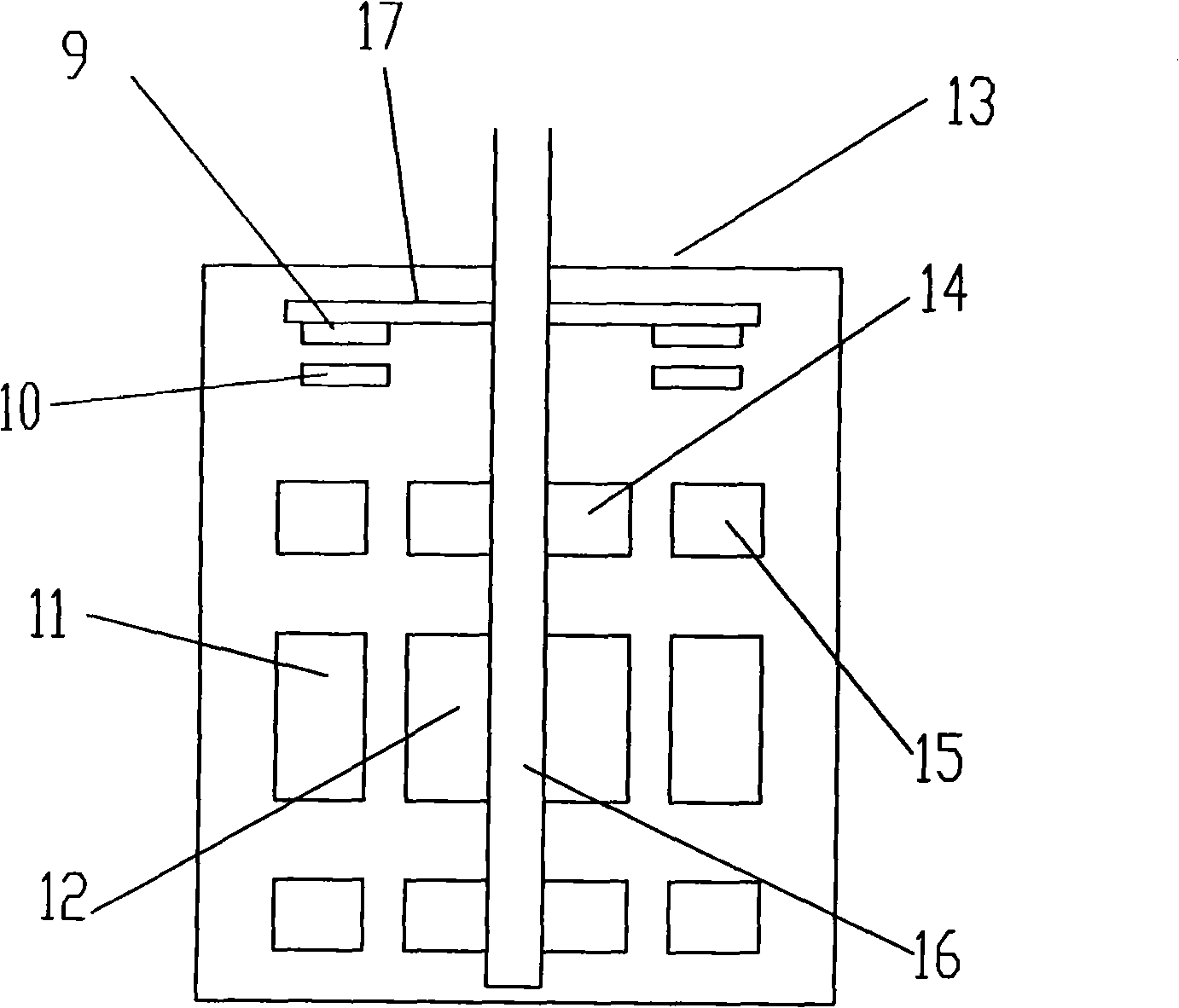

[0028] figure 2 Among them, the generator 7 includes a motor housing 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com