Structured thermal transfer article

A heat transfer and structuring technology, applied in heat transfer modification, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of poor volume thermal conductivity of coatings and difficult substrates on three-dimensional surfaces

Inactive Publication Date: 2008-11-12

3M INNOVATIVE PROPERTIES CO

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These coatings typically have poor bulk thermal conductivity and thus require precise thickness control, which is difficult on substrates with three-dimensional surfaces

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0067] metal precursor material

[0068] logo

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

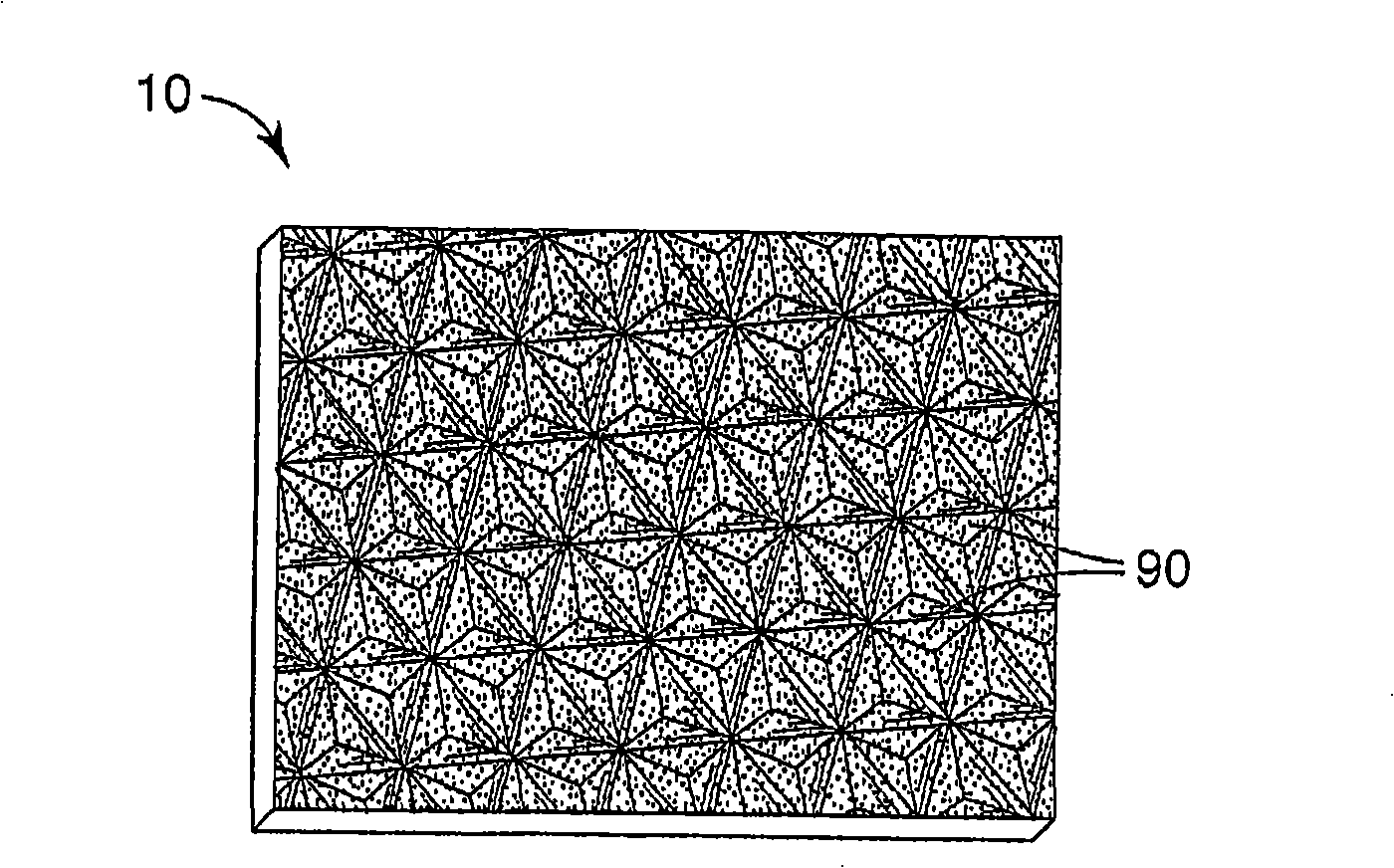

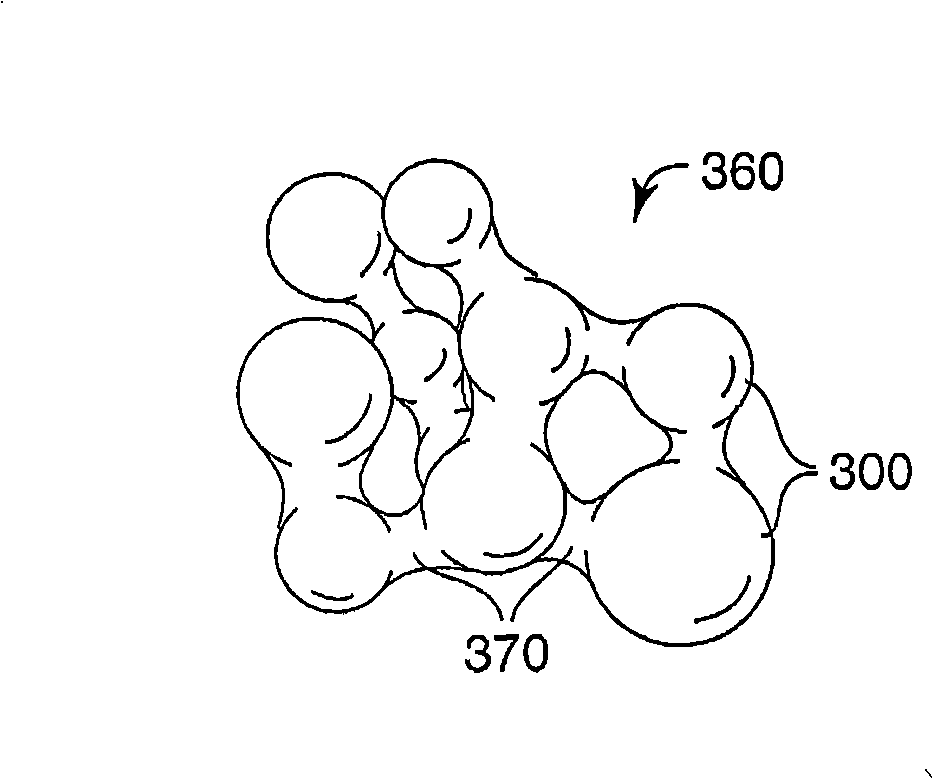

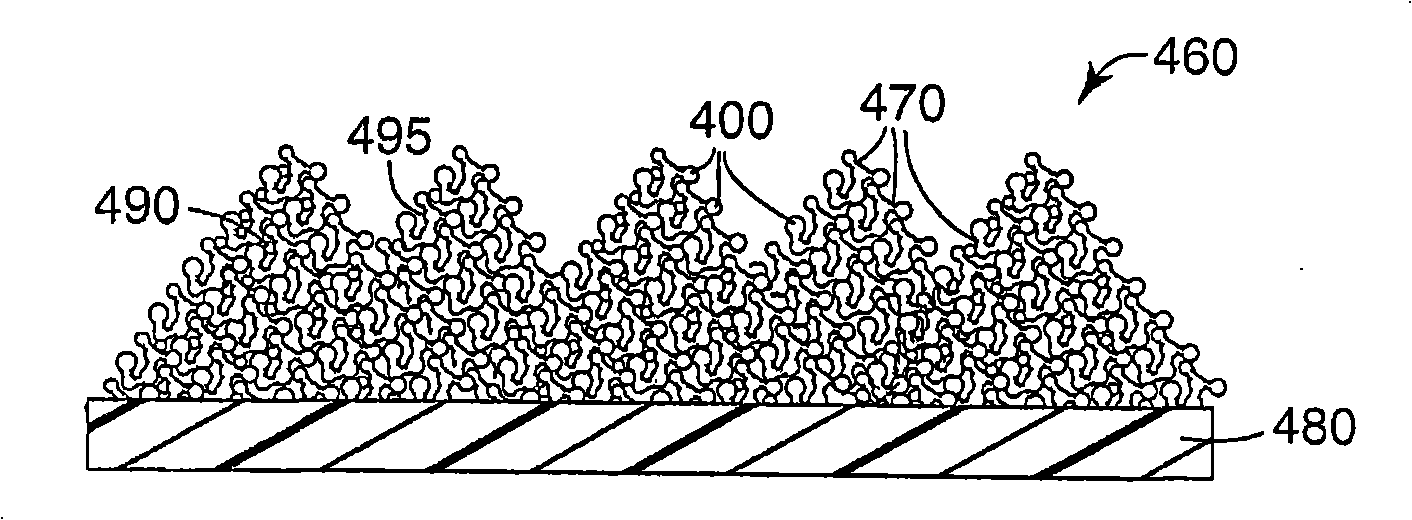

Structured thermal transfer article comprising a plurality of metal bodies and a plurality of interstitial elements disposed between and connecting the plurality of metal bodies to one another. The metal bodies comprise an inner portion comprising a first metal and an outer portion comprising an alloy comprising the first metal and a second metal. The interstitial elements comprise the alloy of the outer portion.

Description

technical field [0001] The present invention relates generally to structured thermal transfer articles. More particularly, the present invention relates to shaped porous metal articles and methods of making and using the same. Background technique [0002] A cooling system for a heat dissipating element includes an evaporating or boiling fluid. The steam produced is then condensed using external means and sent back to the boiler. In order to improve the heat transfer of the fluid at the boiler, porous boiling surfaces can be used. [0003] A variety of porous boiling surfaces can be used including, for example, coatings made by flame or plasma spraying. But controlling porosity and uniformly coating three-dimensional substrates can be difficult using these processes. Other known coatings include conductive particles combined with an organic binder. These coatings typically have poor bulk thermal conductivity and thus require precise thickness control, which is difficult...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F28F21/08

CPCH01L23/44H01L2924/0002H01L23/3733Y10T29/49393H01L23/3732H01L23/3736H01L2924/00F28F13/18F28F21/08

Inventor 菲利普·E·图玛加里·M·帕尔姆格伦

Owner 3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com