Optical pickup

A technology of optical pickups and optical discs, applied to instruments, optical recording/reproduction, head configuration/installation, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

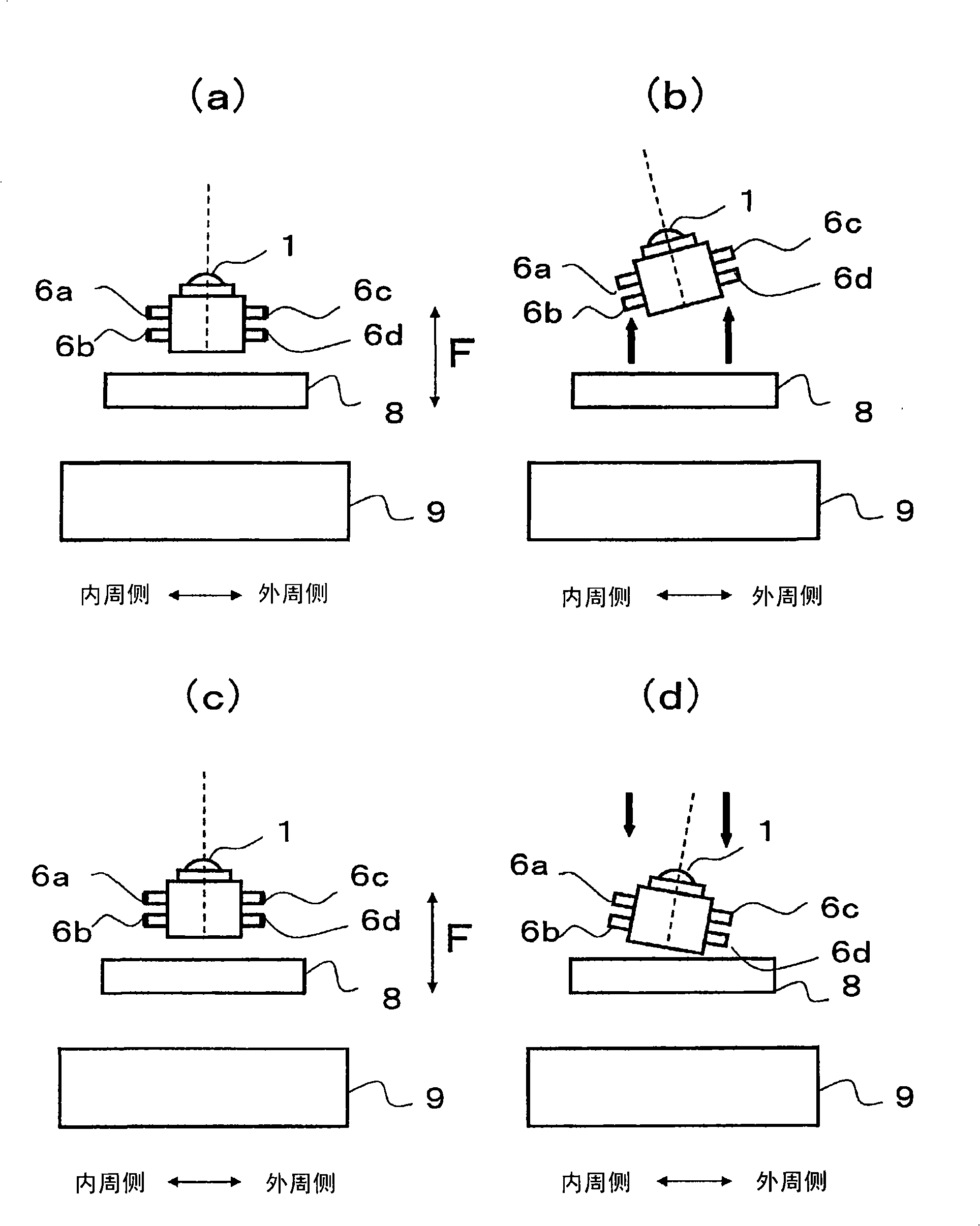

Embodiments of an optical pickup according to the present invention will be described below with reference to the drawings.

[0035]

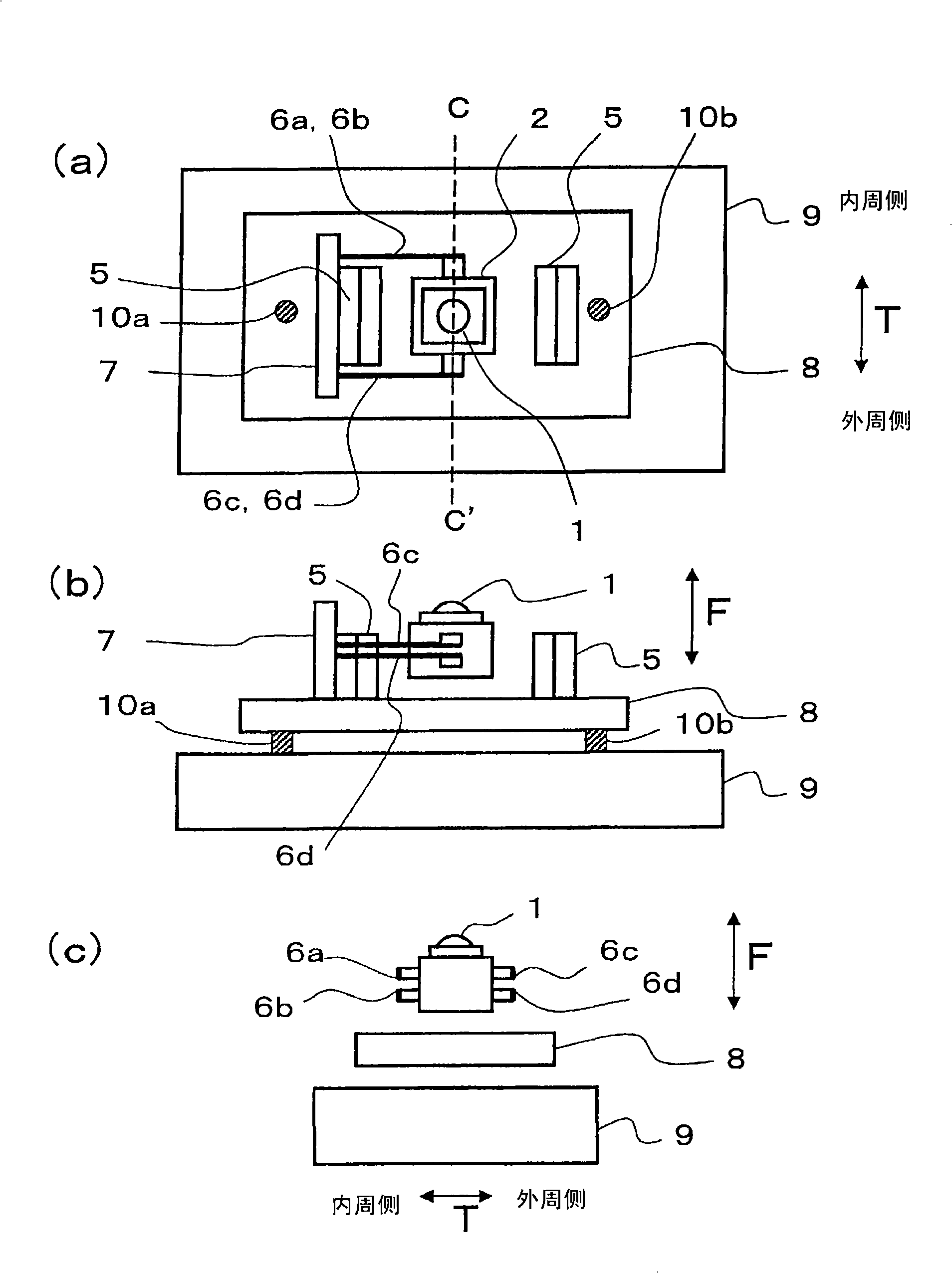

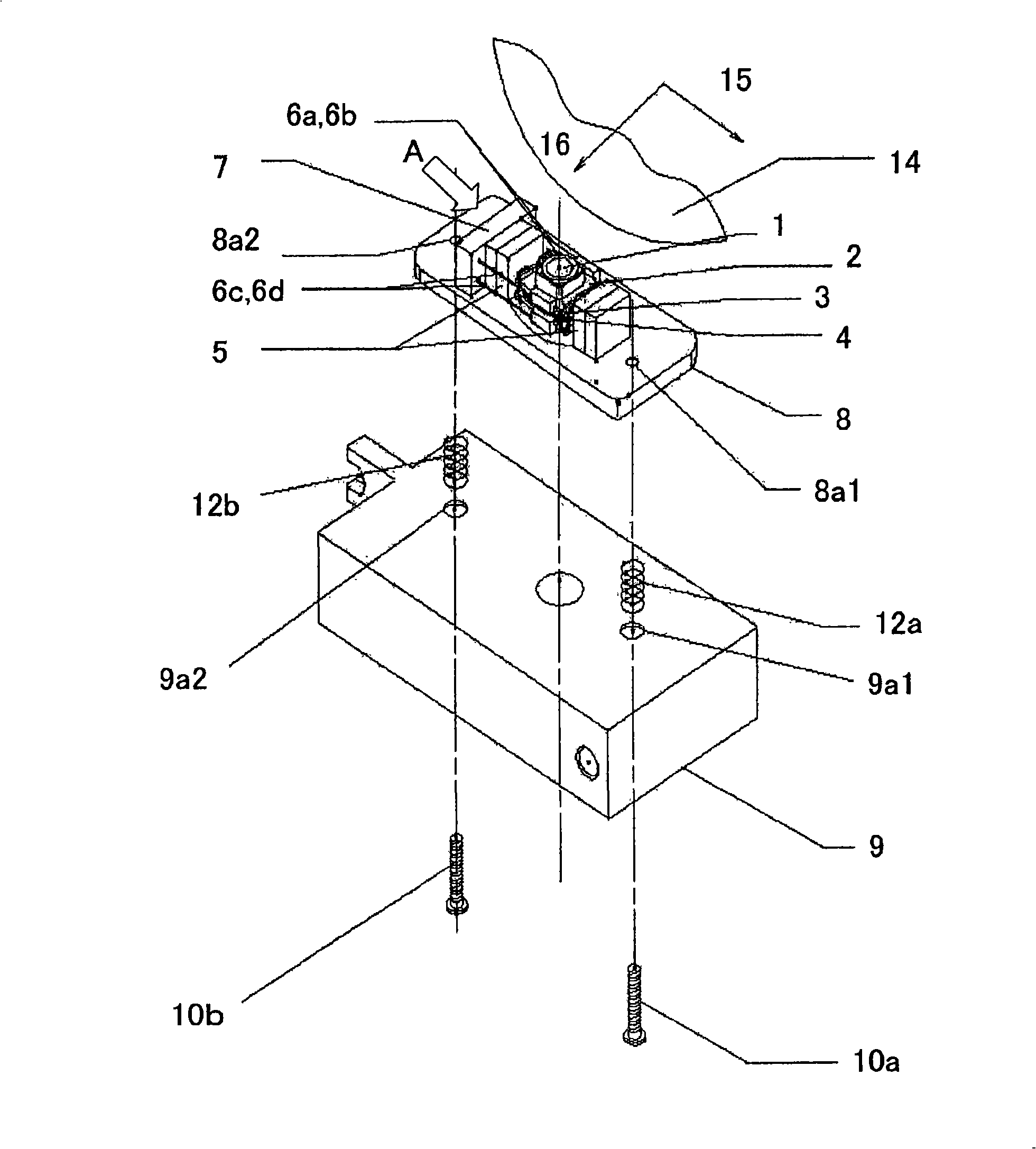

First, refer to figure 1 and figure 2 . figure 1 (a) is a plan view of the optical pickup of this embodiment, figure 1 (b) is from figure 1 (a) The side view viewed from line C~C', figure 1 (c) is figure 1 Cross-sectional view of line C to C' in (a). in addition, figure 2 It is an exploded perspective view of the optical pickup of this embodiment.

[0036]

figure 1 The shown optical pickup includes an actuator base 8 and an objective lens 1 supported by the actuator base 8 via four suspension wires 6a, 6b, 6c, and 6d. The objective lens 1, under the effect of the following lens driving mechanism (lens actuator), can resist the elastic force of the suspension wires 6a, 6b, 6c, 6d. bit. This displacement of the objective lens 1 is carried out in accordance with the instructions of the control unit in the optical disc device d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com